How to decorate a wall with plaster. DIY decorative plaster: types and methods of application, architecture and design (100 photos). "Rose buds" or arbitrary texture obtained using thick paper

Decorative plaster solutions, or decorative textured coatings, do not require further processing or surface finishing. They can be applied to walls and partitions made of any material - be it brick, concrete, plasterboard, wood or ordinary plaster. But the plaster hardens very quickly, so it is quite difficult to carry out finishing work with its help on a large surface.

In addition, the use of decorative plaster to finish a wall requires careful preparation of the surface (treatment with primer, putty, and grouting materials).

Typically, decorative plaster is produced in the form of a dry or ready-to-use thick mixture. The basis of such materials includes a polymer binder, filler (marble or granite chips, sand, lime), on which the texture of the future coating depends, as well as a liquid base - water.

Dry plaster in packages

Decorative plaster often includes other additives that provide additional properties (different surface structure, protective shock-proof properties).

There are also special, separately sold additives for giving decorative plaster a particular color.

Plaster with color additives

If the coating is made in the form of a dry mixture, it must be diluted with water in the required proportion. The plaster is applied quite quickly: first with a brush, and then with a spatula or other tool, or with a special tool immediately (which one should be indicated in the instructions for using decorative plaster). Such a tool can be a roller, brush, trowel, or trowel.

Stretching plaster is always applied using a trowel, working from the bottom up. This plaster is characterized by a denser grain structure. Externally, it is very different from ordinary plasters.

The use of decorative plaster provides many possibilities. For example, using various molding tools, you can additionally create different types of texture.

Plaster consumption is measured in kilograms per square meter of surface and usually ranges from 1.5 to 3 kg.

Decorative synthetic plaster is also used for finishing both interior walls and facades. Depending on the graining and direction of grouting of such plaster, you can create an individual structure for the walls of the interior. This plaster is usually used as a finishing coat, but can be additionally coated with paint.

Decorative plaster in the room

Grout mineral plaster is characterized by a high content of natural grains and does not contain artificial resin. It has a high ability to transmit water vapor. Used for external and internal work.

Before covering the walls with decorative plaster, apply a preparatory layer of ordinary plaster, consisting of spray and primer, along the beacons. The surface of the preparatory layer is scratched, giving it roughness for better adhesion to the decorative layer. A coating of decorative mortar is applied over a well-seasoned preparatory layer. Moreover, it can consist of two, three or more layers.

First, a spray of decorative mortar is applied to the preparatory layer, then a layer or layers of primer and, if required, a cover of the same mortar.

Creating decorative plaster from ordinary

Decorative plaster “Wave”

A variety of textures for future painting can be “depicted” on ordinary plaster. For example, “waves” look great on lime-sand plaster.

To reproduce them on the surface, apply a second layer of mortar in straight or curved strips to fresh or previously rubbed plaster, notched and moistened with water, and smooth it with a spatula. This way a wavy surface is obtained.

Plaster "Wave"

Plaster "Traverine"

To create travertine (lime tuff) on the wall, a thin layer of colored mortar is applied by throwing to the prepared plaster surface. After this, smooth it with a spatula or steel trowel. The result is raised islands on a smooth, worn-out background - the so-called decorative “stones”.

Plaster "Traverine"

About the process of applying this type of joke, watch the video:

Stone plaster

To create a “boulder-like” texture, apply a plastic colored solution to the ground, quickly level it with a trowel and then trim the surface with a hard hair or bristle brush. When trimming, the brush should be held strictly perpendicular to the surface. A hard brush is needed because only it gives clear, sharply defined “boulders”.

Stone plaster

Plaster "Dune"

Under the dunes, the colored solution is also first leveled with a trowel, and then a grater is applied with slight pressure and immediately torn off. The solution sticks to the grater and, together with it, is pulled away from the surface, causing roughness to form on the surface. Externally, these roughnesses are very similar to sand dunes. If you want the dunes to be wavy, you can not tear off the grater directly, but slightly move it to the side. To obtain the texture of small dunes, the solution is first allowed to set a little. After this, it is lightly rubbed, a grater is placed on the surface and it is torn off.

Plaster "Dune"

Watch how to apply Dune to a wall in a short video:

Plaster "Furrows"

The “furrow” texture is obtained using a grinder with semicircular teeth, which is made from a steel strip or wood. It is up to 30 mm wide with gaps between the teeth of 10-15 mm. The teeth of the hammer are sharpened in one direction. Apply a low-flow solution to the prepared soil, quickly level it with a trowel, then take the rule in your left hand and apply it to the solution that has not yet set. Now you need to place the small bit on the rule with your right hand and guide it with the sharpened side of the teeth forward at an angle of 45° to the surface. This way, even furrows are obtained. Their size and shape, naturally, depend on the shape of the teeth of the bait.

Plaster "Furrows"

Plaster “under a fur coat”

By spraying, throwing the solution through a mesh, shaking the solution from a broom or brush.

Methods of applying plaster “under a fur coat”

Spraying through a mesh and from a broom is carried out with any solution (even with coarse aggregate). Only a solution with fine aggregate is suitable for spraying with a brush. To get a dense spray without skipping, repeat it several times until there are no areas left on the surface not covered with the solution. You can also use a special spray device (it looks like a fan).

Spraying plaster under a fur coat

Spraying on the mesh is done like this. Stretch a mesh with cells from 2.5 to 10 mm (the specific size depends on the size of the texture) onto a wooden frame measuring 100 x 100 or 100 x 50 cm. Stretch the wire diagonally from the back of the frame. It is necessary to ensure that the mesh does not bulge or vibrate during operation. Attach the mesh to the wire and tie it. To ensure that the frame is always at the same distance from the wall, nail strips 10-25 cm thick to it.

Spraying plaster “under a fur coat” through the mesh

The frame is placed against the surface of the soil and the solution is thrown through the mesh with a spatula from a falcon. Passing through the mesh, the solution remains on the surface in the form of tubercles. To ensure that your texture is the same, try to apply the solution with the same force.

When spraying from a birch broom, hold it with your right hand, and in your left take a round stick with a diameter of 4-5 cm and a length of 50-60 cm. Scoop the solution onto the broom and hit it on the stick, shaking it onto the wall surface. The size of the resulting texture will depend on the thickness of the broom rods, the thickness of the solution and the force of shaking. While working, stir the solution from time to time so that it does not separate.

Spraying plaster “under a fur coat” with a broom

To get a finer texture, spray with a brush. It is better to use a stiff hair brush or (the best option) a bristle brush. The brush is held with the left hand and, having been dipped into the solution to half the height of the hair, is brought to the surface with the bristles up. Then they pass along the bristles with a stick or board (it is held in the right hand), and the solution flies off the brush onto the surface to be plastered. A thick texture will remain on the wall, similar to the pile of a fur coat.

Brush for applying plaster “under a fur coat”

To obtain a texture similar to snow flakes, spraying is done with flakes of a creamy plastic solution. The wall will be especially impressive if flakes of white mortar are applied to colored plaster. In this case, the colored solution is first applied, leveled and rubbed, and then sprayed over it. This must be done without waiting for the plaster to dry.

To create a texture with a sponge, apply a solution of a creamy consistency to the soil, quickly level it and immediately apply face blows to it with a sponge. After this, a relief remains on the surface of the plaster, the appearance of which depends on the shape of the pores of the sponge. To prevent the solution from sticking to the sponge, it must be moistened with soapy water and lightly squeezed.

Instead of a sponge, you can use a relief roller

To obtain relief patterns on an unhardened plastered surface, you can use special stamps or any convex objects: shells, dense leaves, branches, etc. Pieces of stone, brick, multi-colored glass fragments, shells can simply be pressed into the still soft plaster. It will harden and hold the mosaic together.

To give relief to the plaster, you can use a variety of objects.

Sgraffito plaster

Another method of decorative wall decoration using plaster is called “sgraffito” (scratched). This technique involves scraping off thin layers of specially applied colored plaster. If there are several such colored layers, the resulting pattern will be voluminous and multicolored, reminiscent of a fresco.

Wall finishing using the sgraffito method

Now let's move on to considering techniques for decorating walls using terrazite plaster. This type of plaster consists of a large amount of fluff lime mixed with white cement, white sand, marble chips, glass, mica and other materials. What makes terrasite plaster special is the addition of mica and anthracite fines (up to 10% of the volume of cement).

A type of terrasite plaster

Plaster-hatching

The “hatched” texture (straight or shifted strokes) with irregularities from 2 to 5 mm is obtained from fine-grained mixtures using a freshly applied solution. The solution (in the interval from 1 to 6 hours after application) must be processed by notching with nail combs or toothed scrapers. The applied cement mixture can be treated with a Troyanka or scarpel. Work on the hardened mortar begins no earlier than 6 days after its application.

Plaster "Rock"

The rock-like texture resembles crushed stone, and is made from hardened mortar with coarse aggregate, hammered with a chisel or tongue. The tongue and groove is driven into the mortar, thereby knocking out pieces and leaving indentations that form a uniformly grained surface. If the processing is carried out with a chisel or a scarpel, cutting off pieces of mortar, the surface will have the appearance of torn or chipped natural stone.

Technology of application and texture of stone plaster

Before processing, the surface of stone plaster is divided into separate “stones”. To do this, using a chalked cord, lines of rows of “stones” or rusticated “seams” are punched, as well as straps and other straight parts. After this, they begin to finish the plaster to suit one or another texture.

Texture “under a fur coat” performed with different tools. If you perform notching with bush hammers with large teeth, the result will be a coarse-grained texture, with small teeth - a fine-grained texture, and when forging with a tongue and groove, a particularly coarse-grained texture will be obtained. Keep in mind: with large and long spikes of bush hammer teeth, the texture is deeper and larger.

Under shading The work with grooves is done with a bush hammer, only instead of teeth it should have blades. The depth of the grooves will be determined by the size of the teeth. The first forging is carried along the line marked with the cord, and the subsequent ones are parallel to it. To obtain a texture with the entire surface divided into strips, you need to use a trojan or gear.

Bouchard and Trojan

Texture “under the dunes” on stone plaster it is done with a chisel. First, the surface of the wall must be cleaned with steel brushes or rubbed off with stones. And then from a well-compacted and rubbed surface of the plaster, you need to cut off a thin layer so that small depressions are formed.

Types of chisels

Under torn stone or roughly chopped sandstone invoice made with tongues, chisels, scarpels. First, apply a solution to the surface in a layer of 4-6 cm, compact it and divide the surface into “stones”. When the solution has set, they cut through or perform rustications, and then treat the surface as necessary to obtain the texture. A chisel or dowel is driven into the applied hardened plaster and pieces of the mortar are broken off in different places to form large irregularities. If you want to get the texture of hewn sandstone, use a chisel to chop off small pieces of plaster.

Fur coat finish and torn stone finish

Coarse-grained and fine-grained textures received in two doses. First, cement mortar is applied - in small or large throws - then a mortar for stone plaster is prepared and applied in a layer up to 10 mm thick over the set layer of soil. The top texture can be fine-grained or coarse-grained, depending on the filler.

Application of Venetian plaster

To achieve the best result, the surface to be covered with Venetian plaster should be as smooth as possible, uniform (white) and non-absorbent. You cannot apply plaster to wood and metal - over time, the coating will crack.

Venetian plaster

Tools for Venetian plaster

To prepare and cover walls with Venetian plaster, you will need the following tools:

- two brushes - maklovitsa and flute,

- roulette,

- long ruler

- level,

- pencil,

- syringe dispenser,

- measuring cups,

- containers for mixing materials,

- mixer,

- ladder,

- bucket with water,

- sanding paper (no. 120 and 220),

- sanding float,

- two stainless steel smoothers 250 and 200 mm wide,

- wide and narrow spatulas made of forged polished stainless steel.

It is advisable to round off the working edges of the tools and polish them with fine-grained sandpaper, completely removing scratches, burrs and other defects.

Before applying Venetian plaster, make sure the base is thoroughly prepared. If the base is not properly prepared, cracks may appear on the surface that cannot be repaired.

Stages of applying Venetian plaster

The depth and transparency of the coating is achieved using a special application technique.

The master applies several thin layers of coating to the wall, consisting of randomly located spots of material. The combination of many such spots and their layers creates the illusion of depth in the pattern of natural material. The number of layers varies from 2 to 10, but the total thickness hardly exceeds 1 mm. Each layer must be smoothed (pressed) manually with a spatula, float, or grater until a completely flat, smooth and glossy surface is obtained. Even an experienced specialist takes almost an hour to work with 1 m² of one layer.

The first layer is usually made of a material that contains finely ground marble chips. It is applied to the surface with a steel trowel or spatula in the same way as putty. After 4-6 hours, covering and glazing layers can be applied to this layer, which will create the texture of the coating pattern.

Applying the first layer of plaster

If you need to get a matte finish, then the second and subsequent layers are made of the same material as the first. The glossy surface is obtained using a finely dispersed material mixed with the selected dye.

When starting work, use a spatula to spread a small amount of material onto the working surface of a long trowel. Now start working from any top corner. Proceed in the same way as when applying finishing putty, applying the mixture in an even layer. Cover areas near the floor using a bottom-up motion. Press the trowel firmly against the wall, holding it at an angle of 10-15° to the surface. Make sure there are no gaps.

When the first layer has dried, begin applying the next one.

First, mix the coating material: add dye to it (if you bought a “semi-finished product”) and mix everything thoroughly again.

Next, apply a small amount of material along the edge of the short trowel with a narrow spatula and spread it in random strokes using short arc-shaped movements. Each movement should be approximately equal to the length of the iron. If a sag forms on the wall at the end of the movement, disperse it with a straight-line movement at an angle to the sag line. Alternate the movements of spreading and accelerating and randomly change their length and direction. Apply the coating on the floor using arcuate movements, starting from the bottom. Finish when an area of approximately 0.7 x 0.7 m is covered with the second layer.

Stage of applying Venetian plaster

Now level the coating in this area with long strokes of the trowel in random directions. Every 2-3 strokes, clean the ironer and wipe it with a damp cloth. Increase the pressure and tilt of the smoother plane to 20-25°. The result should be a uniform thin layer.

After 10 minutes, begin to smooth the coating with the edge of a wide (200 mm) spatula. Movements with a spatula from top to bottom should be slightly crossing. As gloss appears (this occurs from heating and polymerization of the material), release the pressure on the spatula. If this is not done, the resulting crust may be damaged.

To finally polish the surface, you need to smooth it with a clean trowel. At the same time, it is pressed firmly with both hands and held at an angle of 5-12° to the plane of the wall. When polishing an area near the floor, direct the strokes of the trowel from bottom to top and slightly cross them.

The next stage of applying Venetian plaster

When finished, proceed to apply the second layer to the next area, repeating all stages of the operation sequentially.

The pressure on the stroker is released at the beginning and end of the movement (as when scraping). This allows you to change the thickness of the material layer. When smoothing and glossing, the movements of the trowel should cross the boundaries of adjacent areas. To get the desired texture, change the size of the trowel, the length of the strokes, the spaces between them, as well as the force of pressure on the tool.

When working in corners, openings, ledges and other difficult places, direct the spreading movements from the border line into the area. If necessary, use a spatula instead of a smoothing iron.

While the second layer is still wet, begin applying the next layer in randomly placed spots. At the same time, the entire finishing cycle is repeated in sections. Apply as many layers (moleno of different colors) as needed to achieve the desired result.

If you accidentally damage the surface, use a narrow spatula to apply the first layer of material to the area and around it. When it dries, repeat the entire operation of applying the next layer.

You can use the room after all the work is completed within a day, but it’s better not to rush. The walls will dry completely in a week.

Venetian plaster

After all layers have dried, you can cover the walls with natural beeswax. It will enhance the shine of the coating and give the feeling of an optical illusion. Waxing gives the coating additional moisture resistance. There is no need to apply wax to some plasters produced today: all the necessary components are already contained in the material.

Wall decoration with decorative plaster: 10 types of textures with your own hands

To create antique interiors, you cannot do without decorative plaster, because the best solution for artificially aging walls simply does not exist. Amazingly cracked wall covering, traces of corrosion, patina - all these effects are unthinkable without a plastering solution.

Replacing decorative plaster with paint will not only “reduce the cost” of the interior visually, but will also reduce the number of exquisite design options by hundreds of times. Apparent savings will lead to additional expenses, because over time the paint will begin to crack and peel off from the walls, but this will not happen with plaster for at least ten years.

Compared to paper wallpaper, smooth decorative plaster looks much more prestigious. In addition, there is no need to calculate the number of rolls and make sure that they are from the same batch (due to the difference in shades). Wallpapering is not complete without adjusting the pattern, so there will be a lot of scraps. Due to uneven walls, the canvases will have to be overlapped, because that when glued end to end they will “lie” crookedly. A repeating wallpaper pattern initially cheapens the design, creating the impression of a serial design. Not to mention that the edges that bend over time make such walls look sloppy.

An ideal alternative to wallpaper from the point of view of convenience, versatility and economy is decorative plaster, which can be used without worrying about the listed details.

This amazing finishing material is sold in Moscow and other Russian cities through the Clavel-Trade trading network. The range of decorative plasters is regularly updated with new types. You can select an effect, order a product, get acquainted with its characteristics and see photos of finished coatings in interiors on our website.

Types of decorative plaster by composition and how best to use them

Depending on the recipe, decorative plaster is divided into 4 types:

limestone (Venetian), the main components of which are lime and micro-marble. Its extinction period is estimated at two to three years, which determines the strength and durability of the coating. The creation of modern interiors with “marbled” wall decoration is not complete without a finishing material based on slaked lime, prepared for at least 3 years.

Silicate plaster. In addition to “liquid glass”, the plaster mixture includes natural fillers - marble, sand, talc. Thanks to them, plaster has a unique quality - to maintain its original appearance, despite exposure to moisture.

Acrylic decorative plaster. Eco-friendly water-based latex combined with ground marble and a silicate mineral called wollastonite is excellent for finishing facades and walls inside buildings. If finishing technology is followed, the service life of acrylic-based decorative plaster reaches 15 years.

Silicone plaster is similar in composition to acrylic with the addition of polysiloxane polymers, in other words, silicones. The coating of these components withstands weather surprises, including fluctuations in humidity and temperature changes, which is why silicone mortar is used for facade work.

You can make truly profitable purchases by visiting the salons of the Clavel-Trade network. The assortment always includes lime, silicate, acrylic and silicone plasters, which will help create any type of decor both in interiors and for exterior use.

Types of textures

Decorative plaster differs not only in composition, but also in the different tactile properties of the coating.

Which interior plaster is smoothest to the touch: Venetian, textured or structural?

One of the most pleasant to touch is the Venetian one. It is used to create a perfectly even, smooth coating. Using a lime-based composition, it is easy to imitate a marble surface with the inherent warmth of stone and mirror-like smoothness. In contrast to the prices for the most budget finishing with natural stone, the cost of walls with Venetian plaster is an order of magnitude lower.

Whether the surface will be very or slightly rough when using structural plaster depends on the size of the filler particles included in the composition: silicate, dolomite, barite or marble. If they do not exceed 1 mm, then you will not be able to feel the relief with your hand. Larger fillers (from 1 to 3 mm) will make the coating textured and slightly rough to the touch.

Due to mineral additives, structural plaster masses have high strength indicators, so they are rarely used for interior decoration. They are mainly used to cover facades and walls in high-traffic areas: corridors and entrances.

Textured plaster creates a very smooth and pleasant to the touch relief. It is formed due to the high viscosity and plasticity of such a material. The particles included in its formulation with a diameter of 0.1 to 0.5 mm are responsible for the microrelief of the coating, however, it will not be rough: only velvety.

Is it expensive to decorate walls with decorative plaster?

What does the price of the finishing coating consist of?

The first thing you should pay attention to is the thickness of the layer. Everything is simple here - the more abundantly we plaster the walls, the greater the material consumption will be. For a rough calculation, you can use the following formula - 1 additional millimeter of coating thickness requires one kilogram of plaster per square meter.

The second is the number of layers needed to create a certain effect. In this case, the labor costs of the master and the time required to complete the entire “pie” increase, because Each new layer requires careful drying.

Plastering the walls yourself can be cheap, but then you will have to forget about creating an exquisite designer interior.

The cost of finishing work is also influenced by the quality of its execution - the higher the qualifications of the finisher and the more time he spends on creating the desired effect, the higher the cost of execution will be.

The complexity of the finishing project and the exclusivity of the implemented effect will require additional costs. The same applies to the saturation of the color scheme, because the more intense the color of the walls, the more colorant you will need.

Today, decorative plaster is gaining popularity in wall decoration at home, which allows you to obtain different textures and implement many different ideas for interior design. To do this, there is no need to purchase expensive components and compositions.

In this article we will look at different manufacturing optionsDIY decorative plaster from ordinary putty. Let's find out the features of the material and decide on the types of putty mixtures. We will also dwell on the advantages of decorative plaster fromDIY putty.

Decorative putty plaster is a wide field for experiments and non-standard design solutions. You can create different textures and stylistic solutions with your own hands, including:

- Apply stains and colored spots to the work surface in a chaotic manner.

- All kinds of images on a smooth plane.

The process of applying textured putty plaster at home should begin with preparing the working tool. The picture shows the entire range of necessary equipment for the upcoming work.

You can add to the tool kit:

- sandpaper;

- sponge;

- tassels;

- roller and other accessories for wall processing.

The use of a particular tool depends on the type of structure being created. Before starting work, we need to remember what is included in the process, what stages await us:

- Work planning.

- Preparation of the working surface.

- Creation of a specific texture.

- Finishing the walls.

Advantages of decorative putty plaster

Speaking about the advantages, we should note the acceptable cost of the product and long service life. This is the ability to select the required proportions and prepare them. Easy to apply and further maintenance. Last but not least is the issue of ecology.

This mixture is suitable for treating walls in rooms with high humidity. The plastic solution has antibacterial properties. Putty plaster makes it possible to apply an original design to a smooth surface.

Types of putty mixtures

There are many ways to treat walls. We will focus on the two most common putty mixtures:

- Under a stone.

Bark beetle is a common decorative plaster that you can make yourself. Most often it is applied to the outside of the walls. For this you will need:

- A universal cement-based material for exterior use.

- Marble chips or other fine filler.

- Water dispersion paint.

- And also a primer.

This plaster is done by hand as follows:

The dry mixture is thoroughly mixed with crumbs in a proportion of ¼ and diluted with water to the consistency of thick sour cream. The composition is applied to the wall in a thin layer. Movements are rotational-translational and using a small spoon.

Grouting can be done in two ways, as shown in the figure. The process is carried out after the applied layer has set in 5-7 minutes. The final stage involves priming and painting.

Do-it-yourself stone finishing with decorative plaster is suitable for rooms and building facades. This is a new finishing material, which includes:

- Quartz ground to sand.

- Mica in the form of dust.

- And additives as dyes.

The work process is, first of all, thorough cleaning in order to achieve a level of adhesion. Otherwise, it will not be possible to achieve the required adhesion between the plaster and the wall.

How to make decorative plaster yourself

To create decorative plaster from simple putty, you need to take 6 kilograms of powder and mix with two liters of water using a mixer.

Next, add 200 grams of PVA glue and mix again. The solution should be paste-like and not run off the instrument. If the finished mixture is intended to be applied in a damp room, it makes sense to add a little cement to the composition.

Thus, you can make decorative putty for walls with your own hands.

You can purchase ready-made polymer compositions in the retail chain. If dry mixtures are initially used, they are diluted with water, following the manufacturer’s recommendations. The mixture should not be too thin and not too thick.

You can mix the composition manually and/or using a mixer or a drill with an attachment.

When adding color, you need to remember the proportions in order to prepare putty of a similar shade in the workflow. Otherwise, the color will be uneven and light joints may appear on the working surface.

If the composition of the filler involves the use of sand and/or stone chips, you should remember the proportions. Crumbs can be added no more than 10-15% of the total volume of the mixture.

If you ignore the specified proportions, the applied composition may peel off and will not adhere firmly.

Applying the base layer

Working with a decorative surface involves initially applying a simple pattern. This is a kind of learning for a beginner, an opportunity to understand what he can do. The workflow steps are as follows:

- Markings are applied to the wall or part of it, and the necessary parts are sealed with paper masking tape.

- First we prepare and then apply the putty using a spatula. The thickness of the applied layer should not exceed 10 mm.

- The applied solution should set a little and only after that you can start decorating the surface: step by step.

note!

We decorate each section from top to bottom, and not vice versa.

Creating a decorative surface

You can create a decorative surface using:

- roller;

- notched trowel or trowel;

- other available means.

Read about it below.

Roller work

A special grooved roller is used for this work. Medium pile length. It is available with a ready-made corrugated surface, but the price of the product is high. Therefore, at home you can use a regular foam roller with large pores. If you wish, you can use a sharp knife to cut out different patterns on the roller. You can build such a tool yourself by wrapping a coarse cord or an ordinary plastic bag around the tool.

Working with a notched trowel and trowel

You can use a spatula:

- With U-shaped teeth.

- Or V-shaped teeth.

It all depends on the size of the stroke and the direction of work. Retail offers the purchase of shaped, rubber tools with teeth. They can be used to treat the surface and imitate the texture of wood.

Using a regular trowel you can create a unique design. It is necessary to press and move the tool away from the wall, creating a “fur coat” texture on the putty. And if you smooth out part of the relief during the process, you can get an imitation of stone plaster.

Working with improvised means

To apply a drawing to the wall at home, you can use the means at hand, namely:

- With combs.

- Film.

- A crumpled piece of paper.

- Foam rubber.

Applying a pattern with crumpled film gives the effect of silk. Combing the moistened surface with a comb will give you an original weave, while working with a piece of sponge will give you a grainy surface.

Painting, varnishing

Colored plaster can be used for finishing facades and carrying out interior work. The working surface is pre-primed and allowed to dry completely. Painting putty can be covered with one or several layers. Let's take a look at one of the simplest ways:

- Initially, the wall is painted evenly in one general tone. To do this, use a roller and a long pile or roller.

- Then the painted surface must dry completely, after which it is covered with a second layer. In this case, the working tool is replaced. The second layer is applied with a short-nap roller. This allows you to paint over the protruding parts of the relief, nothing more.

- After the applied second layer has dried, acrylic varnish is applied to the wall to fix the dye and add gloss, to which, if desired, glitter is added - these are glitters.

Roller texture embossing patterns

You can create a textured surface with your own hands using a roller. The thickness of ordinary decorative putty should not exceed 3-5 millimeters. A thicker layer may crack. The mixture is distributed by random movements with a spatula, as shown in the figure.

Using a stencil roller you can create spectacular patterns. Stencil printing is the most common way to create textures and designs on the wall.

Advice!

Wet the roller every time you apply a pattern.

Secrets of the masters

Applying plaster from ordinary putty has its secrets, which professionals and our consultants share.

Before work, the surface should be prepared. The preparation process includes:

- Surface cleaning.

- Degreasing.

- Removing minor flaws.

- Cementing crumbling areas.

On a note!

The putty has poor contact with concrete and practically does not adhere to oil-painted walls.

To avoid negative consequences, it is necessary to coat the concrete with a primer, and apply notches to the remaining paint, maintaining an interval of 50 mm. If you doubt the quality of the wall or its previous covering, you can use a special mesh. You just need to stick it on the surface.

Remember,

that a highly diluted composition hardens quickly.

Working containers and equipment, including spatulas of different sizes, must be thoroughly washed after work.

It is not advisable to take long breaks in work, otherwise the texture will not look the same.

It is necessary to paint the prepared areas 24 hours after the applied material has dried.

For your information:

When calculating the required amount of paste, less material is used for smooth plaster than for an uneven surface. In numbers, this is approximately 9 grams per 1 m2 .

For creative people who want to create an original drawing, it is recommended to use different combinations of materials: both standard tools and improvised materials. This was discussed above. Particular attention should be paid to the finishing of the walls and the mixture should be applied to a minimum thickness.

With the help of decorative plaster it is easy and simple to create expressive and unique patterns on the surface of the walls. Admiring the effectiveness of the facade, we can conclude that only specialists can perform such a task. However, it is not. The main role in creating original reliefs is played not by the skill of the specialist, but by the material he uses: decorative plaster.

Types of decorative plaster

It contains special substances: fillers. They help create a beautiful drawing. No special or expensive tools are required for this. But it is necessary to choose the right plaster mixture and know the technology of its application.

The composition of decorative plaster mixtures differs from the composition of conventional ones not only by the presence of filler. If the material is intended for facade (exterior) work, it also includes additional components that ensure increased resistance of the facing surface to moisture, temperature changes, and ultraviolet radiation.

Pattern effects that can be achieved using special techniques for applying decorative plaster:

- aging;

- cracking;

- adding volume;

- rough surface texture;

- "silk";

- planes with different relief depths.

There are three types of decorative plasters:

- mineral;

- textured;

- structural.

They all have their own characteristics, both in terms of composition and application rules.

Mineral decorative plasters

The basis of mineral plasters is natural. Crumbs and dust of various valuable types of stone are used as filler: granite, marble, onyx, malachite. Includes quartz sand of different grain sizes. Cement and gypsum act as binders. Cement-based plasters are classified as façade plasters. Mixtures with a gypsum binder are used exclusively for interior work.

Mineral decorative plaster “Bark beetle” 2 mm. Premium quality. For outdoor use

All types of mineral plasters must be prepared for use by adding the dry mixture to water in the proportion specified by the manufacturer.

The finished mixture can be applied to the wall in several layers. The final stage of work is finishing with wax or painting. Wax serves as a protective and decorative coating.

Since all types of mineral plasters are diluted with water, they do not have a long “lifespan” of the mixture. Therefore, it is recommended to prepare enough mixture so that it can be worked out before it begins to harden. One of the advantages of mineral dry plaster compositions is that they have a much lower price than ready-to-use acrylic ones.

Textured plasters

Textured plasters are dough-like mixtures that can be tinted to any color during the mixing process, or coated with paint after the finishing layer has been applied and hardened. This type of plasters is characterized by unsurpassed plasticity, which allows you to create real masterpieces on the walls.

This effect is achieved due to the mixtures of natural fibers included in the composition, which can be cotton, linen, or wood. Some manufacturers use ground brick as a filler. Using mixtures of this type, you can create relief paintings, bas-reliefs and panels.

The popular “Venetian” plaster is not a separate type of decorative plasters, but belongs to the category of textured mixtures. It is called “Venetian” because of its special composition, which allows the use of a special application technique, which provides a spectacular wall pattern.

Structural plasters

Plasters of this type are heterogeneous granular masses. The binders are potassium silicate (silicate plasters), synthetic latex (latex plasters), and cement-lime composition. There are two types of structural plasters:

- water based;

- solvent based.

Hence the classification of these mixtures: water-soluble and organo-soluble. The main representatives of this type of finishing mixtures are “Bark Beetle” and “Shuba”.

They are the ones most often used in finishing facades. The reason is simple: these mixtures are easy to apply, form an attractive surface pattern, and have excellent wear resistance. In addition, they have one more advantage: reasonable price.

To dilute solvent-based mixtures, white spirit is mainly used. It should be noted that it does not dissolve anything in the plaster mass. He dilutes it to the desired consistency. Therefore, experts call any liquid added to the finishing composition not a “solvent”, but a “thinner”.

Acrylic plaster "Ceresit"

Pebble plaster "Ceresit"

Among structural mixtures, acrylic plaster is the most popular. Its distinctive feature is that it is ready for use immediately after purchase. These mixtures do not require dilution with water or solvent. This fact is their undoubted advantage. In addition, acrylic plasters are much more elastic and durable.

They have higher adhesion rates (adhesion to the base) than mineral and solvent-based structural ones. Acrylics can be applied to almost any surface: wood, brick, concrete, aluminum.

In sealed packaging, acrylic plasters retain their properties from 6 months to 1.5 years. Some manufacturers produce mixtures with a shelf life of up to 2 years. Another advantage of acrylic compounds is that walls treated with them can be painted.

“Small bark beetle”, decorative acrylic plaster for exterior and interior use

The only drawback of these mixtures is their lower vapor permeability than mineral ones. However, it is sufficient to use this material to construct a “wet” facade, which is also a heat insulator.

Specifications

Prices for various types of decorative plaster

Decorative plaster

Techniques for applying decorative plasters

Mineral plasters must be prepared for use by diluting with water. On average, up to 30% liquid is required. All manufacturers indicate the required proportions on the product packaging. Mineral mixtures are applied in two layers.

The use of any plaster compositions requires careful surface preparation. The walls must be inspected for the presence of deep cracks, and make sure that the load-bearing surface is strong enough and does not require major repairs.

The next stage of work is priming. To perform this task, use deep penetration primers intended for external finishing work.

Plastering of the facade begins from the corner of the building. The work is carried out in stages, gradually applying the mixture to small areas. The first layer is the base layer. It is applied with a spatula so as to avoid overlaps and obtain as smooth a surface as possible. For leveling, you can use a spatula with a wide blade or a rule.

The main work on decorating the facade occurs at the next stage of work: when applying the second layer.

Tools for creating a decorative surface

To apply decorative plasters, special textured rollers are used. They differ from ordinary ones only in that they are equipped with rollers with a relief surface.

Depending on the material the roller is made of, there are several types of rollers:

- wooden;

- rubber;

- plastic;

- leather;

- pile.

Standard sizes:

- with a roller width of up to 30 cm (short rollers);

- with a roller width of up to 50 cm (medium length);

- with a roller width of 50 cm (long rollers).

All types of rollers can be roughly divided into textured and structural. The latter have a more relief surface than the former. Textured ones are designed to create an imitation of marble, natural stone, textiles. “Bark beetle” and “Shuba” plasters are applied using textured rollers.

Structural rollers are designed to produce a pronounced relief pattern, consisting of a repeating rather complex pattern. Externally, it creates the effect of voluminous wallpaper. The decorating technique using these tools is more complex than when using textured rollers.

Working with structural ones requires extreme care and attention. The rollers of these tools are usually made of wood or plastic. The use of such rollers requires compliance with several rules.

- Surface decoration is carried out using a base layer that has already hardened and leveled. For application use a liquid mixture. If you work with a dense composition, the recesses of the relief texture of the nozzle will quickly be filled with the mixture, so it will not be possible to obtain a pronounced pattern.

- The pattern is applied in stripes by rolling the roller in the direction from bottom to top or top to bottom.

- Each subsequent strip should fit tightly to the previous one, but not overlap it.

- When decorating walls, they try to avoid putting pressure on the roller. In this case, the relief of the pattern will be of the same depth.

- During work, the wall surface is moistened using a sprayer or a paint brush.

- The roller is periodically dipped into a container of water, washing off the adhering plaster mixture from it.

Prices for textured rollers

Textured rollers

How to get the “Marsiniada” invoice

To obtain the “Marsiniada” texture, structural plasters are used. Using this technique, they create a stylish and effective pattern that is suitable for decorating walls indoors and outdoors.

According to the instructions, the structural mixture Desan Versagele is required for plastering. However, the surface pattern is obtained using a special technique, and not due to any features of the composition. Therefore, to create the “Marsiniada” texture, you can use any suitable structural plaster.

Execution technique

Step 1. Open the container with wet plaster and thoroughly mix the composition with a spatula.

Step 2. Using a trowel or stainless steel spatula, apply the mixture to the wall, trying to obtain a uniform layer up to 5 mm thick.

Step 3. Immediately after applying the plaster, it is covered with thick plastic film. Smooth out all the waves with your hand so that the film sticks to the plaster mixture.

Step 4. Perform a series of movements with the palm, trying to displace part of the film without leaving a fingerprint. In this way, a thin layer of plaster is spread over the entire surface of the wall. Make sure that no air bubbles remain under the film.

Step 5. Wait for the relative hardening of the plaster mixture (at least 12 hours).

Step 6. Carefully remove the plastic film.

Step 7 After the walls have completely dried (after 24 hours), treat the surface with fine-grained sandpaper.

Step 8 Using a dry paint brush or rag, remove dust from the wall.

Step 9 Apply a layer of finishing primer with a brush or roller.

To more reliably protect the plastered surface, you can apply a layer of varnish or paint to the wall. To perform this task, use any most convenient tool: spray gun, roller, paint brush.

An important point: rub the varnish or paint over the plaster with a soft foam sponge until it dries. This allows you to fill all the recesses of the relief pattern and gives the surface a finished look. While working with a sponge, periodically rinse it thoroughly with water and wring it out. You can apply several layers of varnish or paint. In this way, the desired shade of the façade color is obtained.

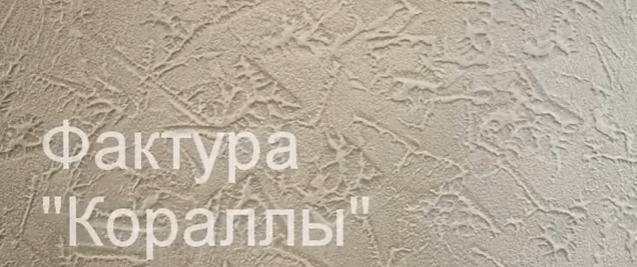

How to get the “Corals” texture

To obtain the “Corals” pattern, structural plasters with fine or medium-grain filler are used.

Step 1. Open the container with the composition and mix it thoroughly.

Step 2. An even layer of plaster mixture is applied to the wall. Use a trowel, trowel or stainless steel spatula.

Step 3. Smooth out the applied layer using a spatula with a wide metal blade.

Step 4. Take a spatula with a rectangular blade and gently press it against the wall surface. This is an important stage of work, so you need to be extremely careful.

To obtain a drawing, follow the following technique:

- apply the spatula to the wall with the entire area of the sole;

- remove the spatula with a jerky movement;

- apply the spatula to the wall, changing its direction: perpendicular or oblique relative to the previous imprint;

- tear off the stuck trowel sole from the plastered wall.

Step 5. After 15-20 minutes, use the same tool to slightly smooth the pattern, leveling its relief.

Step 6. After 24 hours, the wall is treated with fine-grained sandpaper.

Step 7 Apply a protective composition: finishing primer, varnish or paint.

This way you get a beautiful relief pattern “Corals”. The print density can be any. But the most effective pattern is one without overlapping prints.

Video - How to apply decorative plaster with your own hands

Video - Decorative plaster, granite chips based on natural stone

The order was for painting and plastering work in a kitchen with an area of 8 sq.m. It was necessary to plaster, putty the walls and apply decorative plaster. The master did everything carefully, I liked the quality. Satisfied. There was a technical break - we were waiting for the walls to dry. Decorative...

I also did the plaster quite quickly. It was critical for me to get everything done on time before the end of September. The master met the requirements. Everything is fine.

Grade 5Pros: In 9 days on an area of 100 m2 we received: perfectly leveled walls, snow-white ceilings and columns, pearlescent decorative plaster, wet silk and textured travertine plaster, divinely glued designer vinyl wallpaper with a selection! Bonus Lyudmila restored to...

voluntarily began slopes in the bathtub, after the door was vandalized by installers. We received all this luxury for adequate money, according to a pre-agreed estimate. Cons: There are simply none Description: I would like to express my deep gratitude to Lyudmila for the implemented design project! Lyudmila is proficient in all types of decorative plaster application and works with different manufacturers of decorative coatings, skillfully combining them, so for little money she has achieved a very effective renovation of walls and ceilings. The master is truly of the highest level, the work was completed before the agreed time, for an absolutely reasonable price. During the work, you could come to her for advice on what would be better and how to do it, and you always received a qualified answer. Luda is very economical in her approach to materials, almost everything is left, and even the wallpaper (of which very little was purchased))). There is nothing to say about the order after the renovation; of course, everything is clean and tidy. Over the many years of building a house, for the first time we encountered such a golden man, we really had a perfect renovation. I recommend it to everyone, you won’t regret it, a master of deeds and words! Hurry up, otherwise I'm afraid Luda will soon be in great demand!!!

Grade 5+It was necessary to perform decorative plaster on the ceiling in a room of 20 sq.m., install moldings and a cornice with lighting. Andrey Valentinovich did an excellent job! All finishing stages were followed. Before starting work, the master presented a 3D visualization of what the room would look like...

finishing. Also, the master carried out a competent calculation of finishing materials. During the work, Andrey Valentinovich proposed design solutions to hide the imperfections of the walls. The work was completed on time, payment was made after completion of all work, without prepayments. We were very pleased with the result of the work. Our ceiling is now a work of art! Thank you very much Andrey Valentinovich!

Grade 5+Our order was for decorative plaster and ceiling painting. Eduard Gennadievich worked for us as a master. An excellent master, his hands grow from the right place. He worked calmly, in no hurry, measuredly and professionally. We are very pleased with the result. Thank you master!!!

Grade 5I really enjoyed working with Ilya. I chose a specialist based on his work. In the photographs of his work I saw what I wanted to see in my new apartment. I contacted Ilya to apply decorative plaster to the walls. I liked that Ilya took a very responsible, competent and creative approach to...

task. He promptly arrived at the site and took all measurements, provided several paint options, and kept in constant contact with us. Ilya proved himself to be a highly qualified professional, although the cost of this service is far from the highest. He offered his options and listened carefully to our wishes. In a lively discussion, the final version was born, which satisfied all family members. We are very pleased with the result. Ilya is a polite, intelligent, pleasant young man. Understands and feels the customer without further ado. A true professional in his field. Anyone who is still looking for a specialist in decorative plaster, do not waste time, contact Ilya.

Grade 5+Natalia, Lyubertsy, Kotelniki

Order services: Decorative plaster.

Placed an order to remove decorative plaster from a wall and prepare the wall for a new application of a decorative element to the walls. The master arrived and told us that we were mistaken and that in fact we had not Venetian on the wall, but decorative plaster covered with craquelure varnish. Calmed me down...

He said that he would complete the task, and immediately said how. At the same time, he did not at all “powder his brains” about how complex and difficult all this is. I just sat down and relaxed, and the master gave the result within 1 day. The work and professionalism of the master is assessed as the maximum possible according to any of the ratings! He's smart!

Grade 5+