Electric heating of water supply pipes. Heating the water supply pipe in winter

An ideal solution for a summer house, garage, garden plot!

Easy installation and connection.

- Durability and reliability.

- No control system required.

- All you need to do is just plug it into a power outlet.

A set of heating cables for heating pipes (pipelines) EBECO FROSTVAKT is used to protect domestic and industrial water pipes (plastic and metal, with a diameter of up to 100 mm) from freezing during negative temperature, indoors and outdoors.

Snow defrosting systems must remove snow from outdoor objects and must not clog anything at all temperatures and particularly after defrosting. It is also necessary to ensure that melted snow can freely penetrate into the sewer. Area Heating system Composition.

Heating part; armored or reinforced heating cable; fasteners; energy distribution system; automatic system management. In other words, it's small weather station, which controls the activation and shutdown of the system. In addition, this ensures maximum energy savings.

You can also use a heating cable to heat downpipes and downspouts (the connection of the heating and conductive cable should not be inside the pipe), drainage systems air conditioners, soil in greenhouses and heifers.

The “Pipeline Protection” pipe heating cable consists of a self-regulating heating cable Ebeco EBtrace F10, equipped with a 2 - 3 m (depending on the power of the set) connecting cable and a detachable connection, designed for 220 volt sockets with grounding (Euro plug). Day off thermal power self-regulated heating element cable - polymer matrix, depending on heat removal environment. Thus, there is no risk of overheating of the heating cable for heating pipes and pipelines.

To calculate the required power, it is necessary to estimate geographical position object and system requirements. To calculate power in places such as bridges and loading platforms, you need to add 50%. By correctly calculating the values and selecting the system components, the system only works when it actually goes to sleep or when the temperature is close to zero.

To reduce heat loss, thermal insulation material must be installed after the heating cable. If this is not possible, it is recommended to use maximum power. Installing the system on the outer steps prevents them from icing up. Before laying the cable, it is recommended to take care of the thermal insulation of the steps, especially if the bottom is open. When installing a heating cable from a surface, you must remove stones and sharp objects that may damage the cable. The cable is laid on the finished surface and covered with tiles or other coverings.

Can only be used on thermally insulated pipelines, i.e. After laying the heating cable, the pipeline or pipe fittings (taps, tees, couplings, flanges, water meters, etc.) must be thermally insulated. In this case, the heating cable for heating pipes can only be covered with a material that can withstand temperatures from 65C (for example, mineral insulation) thickness of at least 30 mm.

When calculating the cable length, you need to estimate that it will require more vertical transition from step to step. Since heating cable is only installed on horizontal stair treads, for the system to operate as efficiently as possible, the edge of the cable should be as close to the edge of the step as possible. In addition, the design must anticipate and coordinate where the drainage water, otherwise she will freeze very much from the stairs.

One of the most important advantages of such a heating system is that it automatically lays sidewalks, stairs and other open spaces and takes care of your condition 24 hours a day. In the case of platforms, the system can be installed either over the entire surface or only on the tracks. We recommend using the first method as it can be difficult to remove ice and snow from the ruts.

Pipe heating self-regulating cable can be carried out by laying the cable both outside the pipe and from the inside.

Pipeline heating outside is carried out on newly laid water pipes or on water pipes that can be accessed. In this case, the heating cable is fixed to the bottom surface of the pipe or wound in a spiral around the pipe (depending on the diameter and specific conditions at the site). The cable is attached to the pipe using aluminum tape to transfer heat from the cable evenly over the entire surface area of the pipe (aluminum tape must be wrapped around the entire heated section of the pipe). After this, pipe insulation such as Thermaflex, Energoflex, etc. is put on the pipe.

To securely fasten the laid cable, it is fixed at a certain distance with a special mounting strip. The minimum cable bending diameter is 6 hook diameters. After installing the system at an external site, it is necessary to draw up a cable routing plan and indicate the position of the connectors and terminations, heat sensor and heating cable lines.

Heating cables can be secured at connections using clamps. Carefully tighten the cap so that the heating cable does not reciprocate, as overheating of the cable and malfunction may occur if pressed. In addition, the cable may overheat if the laying surface is poorly balanced. The surface is uneven and the overall efficiency of the system will be reduced. As mentioned above, it is also important to ensure good thermal insulation. It is recommended to use modern, certified materials with mechanical strength - emulsion polystyrene foam, hard mineral wool etc. It is necessary to ensure that the heating cable does not touch or insulate the thermal insulation, as it may overheat.

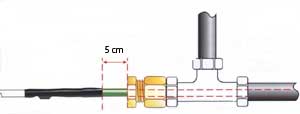

If there is no access to the pipeline and it is impossible to provide it, the pipe is heated with a self-regulating cable from inside the pipe. In this case, at the point where the heating cable enters the pipe, a tee or saddle is installed (for all types of plastic pipelines, we recommend saddles) with a 1/2” or?” outlet. After installing the saddle or drilling a hole in the pipe, a pipe insert is screwed into the saddle, into which the heating cable is inserted according to the attached instructions. ATTENTION! Pipelines with a diameter of 20 mm and below are heated only from the outside.

The heating cable must be laid in accordance with the manufacturer's recommendations. The wiring harness has been installed by a qualified electrician. Do not lay the heating cable yourself, try stretching it through the connecting or end sleeve and immediately load up to 25 kg.

It is not recommended to install the heating cable when low temperatures air, as the cable insulation becomes rigid and increases the risk of damage. If you still need to work, the problem may be resolved by the time you connect the cable to the network. In this case the cable must be disconnected.

|

Heating cables prevent damage to pipelines even in the most very coldy. Cables for heating pipes HTS-GLOBAL (Switzerland) and Kima (Sweden) allow them to be installed both outside and inside pipes with drinking water. Heating of pipes with cable is necessary primarily to protect against freezing of domestic and industrial water pipes laid openly outside the premises, in a cold basement or buried at a shallow depth above the freezing point of the soil. Thermal insulation on pipes at low temperatures cannot prevent them from freezing, but only slows down this process. They will help you get rid of the problems of freezing water in pipes self-regulating HTS-GLOBAL (Switzerland) And resistive Kima (Sweden) cables. |

||

|

Installing the cable inside the pipe.

|

Transition coupling.

|

|

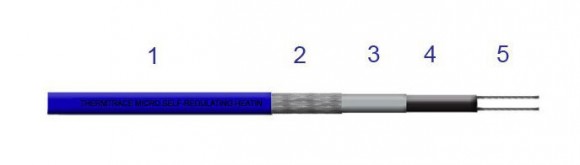

- Self-regulating heating cable for heating pipes 17TTM-2-VOT (Switzerland)

(can be installed outside or inside the drinking water pipe)

Cable power on insulated metal pipe at a temperature of 5 o C = 17 W

Rated operating voltage: 220V

Application area: pipe heating, cable systems heating of pipelines (designed to be placed inside a pipe, including drinking water)

Can be placed inside or on the surface of the pipe.

Price 1m.p.: 480 rub. cut off from 1 linear meter.

♦ Ready-made kits for installation inside a pipe:

1. The kits are made on the basis of a self-regulating heating cable 17TTM-2-VOT (Switzerland)

The length of the supply cable is 1.7 m. Europlug.

not included.

2. Kitsbased on resistive cableKima Therion (Sweden)

Supply cable length - 1.5 m. Without plug.

Adapter brass coupling, Ø ½’, not included.

♦ Ready-made kits for installation outside the pipe:

3. Kits based on NELSON EASYHEAT PGE resistive cable with built-in thermostat (USA)

The length of the supply cable is 2 m. Europlug.

4. Self-regulating heating cable for heating pipes 20TTM-2-VO (Switzerland)

(The heating cable is placed on the surface of the pipe.)

Cable power on an insulated metal pipe at a temperature of 5 o C = 17 W

Maximum temperature: 65 o C

Rated operating voltage: 220 V

Application area: heating of pipes, cable heating systems for pipelines.

Suitable for pipelines laid as outdoors, and in the ground.

Price 1m.p.: 450 rub. cut off from 1 linear meter.

HEATING CABLES FOR PIPES HEATING

To heat pipes, both resistive and self-regulating heating cables are used. Note, however, that a self-regulating heating cable is often the most preferable. This is explained by ease of design and installation, as well as cost-effectiveness during operation due to the main design feature self-regulating cable. Namely, the ability to reduce the power output as the temperature rises. Based on this, it is possible to use a self-regulating cable on pipes of small length and diameter without installing a thermostat. We should not forget about such an important advantage that a self-regulating heating cable provides - it eliminates the possibility of cable burnout. It should be noted that when installing heating pipes with drinking water, when using a self-regulating cable produced by HTS-Global, it can be installed both outside and inside the pipe, for which there is a corresponding certificate.

Cable pipe heating systems, in addition to the heating cable, include thermostats with temperature sensors, mounting devices for installing the heating cable on the surface of the pipe or adapter glands (plumbing coupling) in the case when the self-regulating heating cable is installed inside the heated pipe.

Protection of pipelines with a heating cable is becoming increasingly popular, because at a relatively low cost it allows you to avoid freezing and damage to pipes in winter period and solve other problems in different areas industry.