How to properly insulate a second floor attic. Subtleties of attic insulation in a house with a cold roof. How to properly insulate an attic with rolled materials

Thermal insulation of a residential building will always be the main task solving the heating problem. After all, you must agree that it is not the house that is heated that will be warm, but the one that retains this heat. No matter how good the heating is, without thermal insulation, efforts will be in vain. And to reduce heating costs and make your home truly warm, you need to think about saving heat.

After insulating their home, many begin finishing the attic. Is this necessary? Yes, because it is through the ceiling that a lot of heat escapes. And if you insulate it, the ceiling will not let heat out. From physics lessons, everyone knows that warm air goes up to the ceiling. And if it allows heat to pass through, then such air will simply escape outside. Thanks to this article, you will learn which insulation to choose for your attic to reduce heat loss.

What is home attic insulation?

What is the work involved in insulating an attic space? The technology is quite simple: insulating material can be laid on the floor, in the space between the floor beams and, additionally, between the roof rafters. If we talk about insulating a room located at the bottom of the attic, then it is enough to insulate the floor. If you want to store something in the attic or use it as an attic from time to time, the roof is also insulated.

What materials can be laid in the attic for insulation? In this article we will look at the different options and their pros and cons. Let us immediately note that there are several types of insulation:

- Slab.

- Rolled.

- Sprayable.

- Bulk.

Each of the insulation options is good in its own way. We will select the optimal insulation materials that are suitable for this purpose. You must understand that the choice is yours. Our site will offer you only a list of proven materials for attic insulation, which have won many positive reviews. So, we will consider the following options:

- classic - mineral wool;

- indispensable polystyrene foam;

- expensive, but very high quality polyurethane foam;

- simple and cheap bulk materials such as expanded clay, sawdust or slag.

What are they? What is the technology for laying each insulation and its advantages? Let's find out further.

Insulation with mineral wool

Perhaps only the grandmother in the village has not heard of mineral wool, and that is not a fact. This is the most common insulation for home insulation, which is used both for independent insulation and by professional teams. I would especially like to note basalt wool, which does not burn at all and has excellent characteristics. Why do people love mineral wool so much? Let's look at its positive aspects.

- Ecological cleanliness.

- The property holds its shape well.

- Light weight that does not load the structure.

- Low level of thermal conductivity.

- It is not spoiled by rodents.

- It doesn't burn.

- Soundproofing.

- It has a “breathing effect”, creating a good microclimate.

- Relatively low cost.

- Easy to work with insulating material.

Why is this attic insulation so good? Mineral wool is sold both in slabs and in rolls. It holds its shape well, and you can easily insulate the attic floor, as well as the roof. It is enough to lay mineral wool in the space between the beams and cover everything with hydro- and vapor barrier. This is very important, since the main disadvantage of the material is that it is afraid of moisture. It will destroy the insulation, which over time will lose its original properties.

You can see the technology for laying mineral wool in the video.

Foam insulation

While the grandmother from the village might not have heard of mineral wool, she is definitely familiar with polystyrene foam. One of the simple and affordable insulation materials that is widely used by builders. The main advantage of polystyrene foam is its low cost along with good performance. It is much denser than cotton wool, so it is easier to work with polystyrene foam. It lends itself well to processing and fits into the right place. What else can be noted?

- Low thermal conductivity (lower than mineral wool).

- Low cost.

- Affordable price.

- Soundproofing.

- Insensitive to moisture.

- Easy to install.

- Keeps its shape well.

However, the low cost affects other aspects. Foam plastic has more disadvantages. For example, it burns very well. One spark is enough and the material will immediately begin to melt. In addition, it is non-vapor permeable; you will not get a breathable effect for the walls. And if it is not properly protected, then rodents will seriously wear away the material.

Nevertheless, polystyrene foam is and will remain one of the popular insulation materials. Fires are an infrequent phenomenon; in the attic, the breathing effect is not so important, and if you protect the material, then rodents are not a problem. For the price this is a great option.

PPU insulation

One of the most expensive insulation options due to the complexity of the process. PPU is a representative of sprayed materials, such as penoizol. The insulation technology, at first glance, is simple: just spray the composition from the unit onto the surface, it will increase significantly and fill all the cracks. On the one hand, this is true, but the catch is that such equipment is not easy to find. And it’s not even a matter of the availability of units, but the ability to use them. Such work is trusted only to experienced specialists who have access to the equipment.

The components that make up polyurethane foam are mixed in the unit in an ideal ratio, and the finished composition is sprayed onto the surface, which increases in size. Why is this expensive method so good?

- Environmentally friendly material.

- Light weight.

- Lowest thermal conductivity.

- A monolithic structure is created without seams, which can become cold bridges.

- Insensitive to moisture.

- Adhesion to almost any surface.

- Biostable.

- Soundproofing.

- Rodents do not eat it.

- The quality of insulation is at the highest level.

As you can see, there are really many advantages of insulation. But they are compensated by some factors. Firstly, an insulated attic will not breathe. Secondly, you cannot do the insulation yourself without specialists. Thirdly, such pleasure for the attic will be expensive. Whether it's worth it is up to you to decide.

Insulation with bulk materials

This option can be called the simplest and “quickly” without any problems. All that is required is to pour the selected insulation of a certain layer. What can I use?

- Expanded clay.

- Sawdust.

- Slag.

Expanded clay

The insulation material consists of balls that are poured onto the floor. You realized that it won’t work to insulate the walls. It is divided into fractions: expanded clay sand, crushed stone or gravel. What is the feature of the material?

- Does not burn.

- Environmentally friendly.

- Durable.

- Frost-resistant.

- Has high strength.

- Light weight.

- Sound and heat insulation.

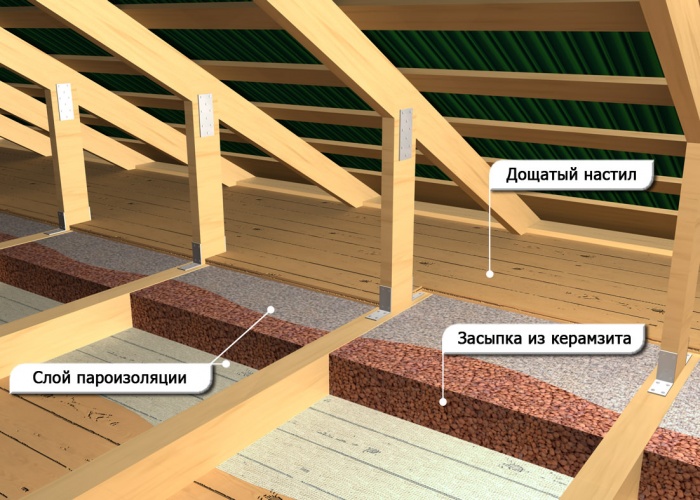

The insulation material is poured over a layer of roofing material, at least 15 cm thick. It all depends on the attic floor and the properties of thermal insulation. So that you have the opportunity to walk on the floor surface, you can make a concrete screed on top, the thickness of which is about 5 cm. All that remains is to arrange the flooring from wood, chipboard or other material.

As for sawdust and slag, the technology is almost identical. The laid material will retain heat, but not as well as the options above. But the labor costs for the work are minimal. If you don’t want to bother, then this is a good alternative to conventional insulation.

Let's sum it up

As you can see, the variety of materials for attic insulation is really large. Each of them is good at something. If you are on a budget, you can use foam. And when you have the means, then choose between mineral wool and polyurethane foam. Some combine insulation materials, eliminating the disadvantages of foam plastic. How? The bottom layer is made of thick foam, and a thin layer of mineral wool is placed on top. Simple and fireproof. However, remember, no matter what insulation you choose to cover the attic, adhere to the technology for its installation. This is the only way to achieve high-quality attic insulation.

Preface. The attic serves to protect the house from cold, moisture and scorching rays of the sun. In addition, heat escapes from the house to a greater extent through the attic. Therefore, the question is “what is the best way to insulate an attic in a private house?” - the owner decides first. We will also look at the issue of insulating an attic in a private house with our own hands in this article and show a video tutorial from the Isover company.

How to insulate the attic floor of a private house

Often the attic, due to its disorganization, remains unused. But it is from the attic that you can make an excellent lounge or bedroom if you choose the insulation wisely and equip the attic yourself as a living space. These issues can be resolved independently, or you can invite a team of builders who can offer several options for insulating the attic of a wooden house, as well as ventilation devices for the attic floor.

The gables and attic floor are insulated using various types of insulation. But more often, three types of insulation are used to insulate the attic. Let's look at the advantages and disadvantages of each:

– Organic derivatives (polyurethane foam);

– Insulation based on mineral wool;

– Bulk insulation such as expanded clay.

Let's figure out what is the best way to insulate the attic of a private house

Insulation of attic with polyurethane foam (PPU)

Polyurethane foam is the most popular insulation for roofs, gables and attic floors. Among its advantages is low thermal conductivity with small thickness. Its use is especially relevant here, because the load on supporting structures is reduced and a significant part of the space in your attic is saved.

PPU is applied by spraying, which creates a monolithic structure that perfectly protects the home from cold and moisture, and also prevents heat from escaping from the house. Polyurethane foam does not absorb moisture and is resistant to mold, preventing the penetration of insects and rodents.

Insulating the attic with polyurethane foam increases the strength of the entire roof due to the creation of a single sprayed structure, without gaps or cracks. Also, polyurethane foam has high strength and wear resistance - its service life exceeds 30-40 years. PPU does not require the creation of moisture and vapor barrier, since it itself perfectly performs the functions of its moisture protection.

Insulation of house floors with mineral wool

Mineral wool is suitable for insulating attic floors and attic floors, as well as for insulating walls and roofs. However, insulation with mineral wool implies the creation of external wind and moisture protection using waterproofing. Mineral wool has a structure that perfectly allows steam to pass through, so on the room side the insulation must be protected with hydro- and vapor barrier.

Mineral wool is laid in the form of rolls or mats. Typically, mineral wool is laid between the rafters, and on the floor - between the joists. Inevitably, seams form between fragments of material and structures. They must be thoroughly foamed and sealed with adhesive tape. For central Russia, a layer of insulation of at least 200 mm is required.

Mineral wool has considerable weight - the load on supporting pillars and ceilings increases significantly. Therefore, before insulating the attic with this material, you should make sure that the supporting structures and roof are reliable. You ask - is this all that can be used to insulate an attic? How were attic floors insulated before the invention of polyurethane foam and mineral wool?

Insulation of the attic floor of a house with expanded clay

Expanded clay is a bulk insulation material; it is perfect for insulating attic floors because it creates a ventilated space while retaining heat. Expanded clay is lightweight, safe and environmentally friendly in terms of flammability. Thanks to the manufacturing technology, expanded clay is strong and durable, resistant to moisture, high and low temperatures.

Expanded clay varies in granule size. Attic insulation with expanded clay is often carried out in the floor area. From the inside, expanded clay needs a vapor barrier coating. The material needs a frame, and this “eats up” part of the attic space. A special “box” is usually created on the floor, into which expanded clay is poured, and a wooden floor is laid on top.

More often, insulation with expanded clay and insulation of the attic with sawdust is complemented by mineral wool or polyurethane foam, especially for horizontal surfaces. You shouldn’t choose just one option to insulate an attic in a private home – you should wisely combine materials. For horizontal surfaces it is better to use bulk insulation; they are cheaper and more convenient to install.

Insulation of attic floors with sawdust and polystyrene foam

Sawdust insulation can be used as one of the methods of attic insulation. But this method is no longer in demand today as before. The main disadvantage is the flammability of the material, which is not suitable for the roof of a house. Insulating an attic with polystyrene foam is easy to implement, but it also has a significant drawback - a fire hazard and the release of toxins during combustion.

Comparison table for thermal conductivity of materials

Video: how to insulate an attic in a private house

The issue of building insulation is now more pressing than ever. Most people start with insulating the walls, but end there; however, as you know, warm air tends to rise and escape through the roof, so insulating the attic floor plays an important role. Like all construction work, insulation should be carried out efficiently. But how to insulate an attic floor to get the maximum benefit?

When choosing insulation for an attic floor, it is important to take into account its heat-shielding properties, strength, and resistance to external factors. The type of flooring will also play a role: concrete and wooden floors have their own characteristics. So, how to insulate an attic floor?

Popular insulation for attic floors

Types of insulation:

- Basalt mineral wool.

- Expanded clay.

- Styrofoam.

- Sawdust.

Mineral wool

Most often, attic floor insulation is carried out using mineral wool. What are its features and why is this insulation so popular?

Mineral wool is laid between the wooden beams of the attic floor

Advantages of mineral wool:

- High thermal insulation. For example, to insulate an attic floor with mineral wool, you will need a layer thickness 3.5 times less than when using expanded clay.

- Easy to install material. This insulation is not difficult to use even for those who are doing insulation for the first time.

- Fire safety. Mineral wool is not easily flammable, therefore, if a fire occurs, it does not serve as a rapid carrier of fire, which, for example, cannot be said about polystyrene foam.

- Long service life. If you lay the mineral wool correctly, it will not roll down and will not create cold bridges.

- Affordable price.

It is thanks to all these advantages that insulating an attic floor with mineral wool is a widely used method of saving heat in a room.

However, this insulation also has disadvantages. In particular, due to its ability to absorb moisture, the insulating layer of mineral wool may no longer provide the same thermal insulation as before. Also, when insulating the attic floor with mineral wool, it is important to follow safety precautions. Mineral wool fibers can cause irritation if they come into contact with the skin, so you should work with it in thick clothing, goggles, a respirator and, of course, gloves.

Expanded clay

Another material for insulating attic floors is expanded clay. Although this insulation is rarely used, it still has a number of advantages.

Expanded clay is a very popular thermal insulator in the past.

Advantages of expanded clay:

- The cost of insulation.

- Good thermal insulation performance. However, to achieve a truly good result, the thickness of the expanded clay layer should be about 35-40 centimeters.

- Fire safety.

However, expanded clay as an insulation also has significant disadvantages:

- More weight compared to other insulation materials. Thermal insulation of a wooden attic floor creates a load on the beams, so when choosing expanded clay, this point should be taken into account.

- Inconvenience during installation. Lifting large amounts of expanded clay into the attic can be a lot of work.

Styrofoam

Polystyrene foam is one of the best materials for insulating walls, so some people decide to use it for thermal insulation of the attic floor. And although polystyrene foam has advantages, it is still not recommended for use.

Attic floor insulated from below with foam plastic

Advantages of polystyrene foam:

- Waterproof. This is a plus compared to the widely used mineral wool.

- Affordable price.

- Easy to install. Lifting sheets of foam plastic and laying them on the attic floor is not difficult.

Despite these advantages, polystyrene foam as insulation has a number of significant disadvantages.

Disadvantages of polystyrene foam:

- High flammability. If the fire reaches the insulation, it is unlikely that it will be possible to extinguish the fire.

- Intolerance to high temperatures. At a temperature of +60°C the material deforms, at +80°C it begins to melt, which causes the release of toxic substances, and at +210°C the foam ignites.

- Fragility. Polystyrene foam can crumble, which reduces its thermal insulation properties.

In view of these disadvantages, especially the unsafety in case of fire, it is better not to use polystyrene foam as insulation for a wooden attic floor. After all, the combination of foam plastic with wooden beams is very dangerous. However, this insulation can be used for thermal insulation of concrete floors.

Sawdust

This method of insulation was very popular earlier, before the advent of modern thermal insulation materials. It is not without its advantages, although they are very insignificant compared to other insulation materials.

Advantages of sawdust:

- The absence of toxic substances, as well as the natural origin of the insulation.

- Relatively affordable price.

If we talk about the disadvantages of sawdust, we can note:

- The need to prepare a solution consisting of sawdust, cement, lime and water. All other insulation materials are purchased ready-made.

- Large weight, which creates additional load on the floor.

- Large thickness of the insulation layer.

Important! Having analyzed all the advantages and disadvantages of different insulation materials, many come to the conclusion that mineral wool is an ideal option, because it has high thermal insulation properties, is fireproof, easy to install, and also has an affordable price. As for its disadvantages, hygroscopicity can be compensated for by installing a vapor barrier and waterproofing, and the inconvenience when laying mineral wool can be compensated by compliance with safety regulations.

Installation process

Having decided on the material for thermal insulation, the question arises: how to properly insulate the attic floor? If we talk about mineral wool, what density should it have and what layer of insulation will be best?

Selecting the layer and density of mineral wool

It is better to do insulation with mineral wool in two layers

In short, the larger the layer of mineral wool, the better. However, you need to remember that mineral wool has its own coefficient of thermal conductivity. The lower this coefficient, the higher the thermal insulation properties, and, therefore, it is possible to lay a smaller layer of wool or have greater insulation efficiency. Mineral wool with a thickness of 15-20 centimeters is often used, however, to ensure increased thermal insulation, a 30-centimeter layer of insulation can be used. It is also worth noting that with equal insulation thickness, two layers of mineral wool are always better than one.

You also need to pay attention to the density of mineral wool, because it varies: from 30 kg/m3 to 220 kg/m3. Thermal insulation properties practically do not depend on density. Denser insulation is used for facades and floors under screed. Mineral wool with a density of 35 kg/m 3 is also suitable for attic flooring, because the insulation will be located on a horizontal, non-loaded surface.

Vapor barrier

Since mineral wool tends to absorb moisture, you need to start insulation by laying a vapor barrier material.

Vapor barrier - the first layer of insulation

Important! It is best to lay a layer of vapor barrier under the wooden beams, because otherwise they will be very susceptible to rotting. However, if it is impossible to install a vapor barrier film under the beams, they need to be impregnated with solutions that protect against rot and mold.

The best option is to lay a continuous layer of vapor barrier, but due to the size of the attic this is not always possible, so all joints must be taped with special tape to ensure tightness. The edges of the vapor barrier must be raised above the level of the future insulation and taped with the same tape.

Thermal insulation

When working with heat-insulating materials, you need to wear special clothing

Next comes the installation of insulation. It must be laid so as to completely fill the entire space between the wooden beams. If we are talking about mineral wool, then it does not need to be pressed or squeezed. It should completely cover the space between the beams, leaving no cracks or gaps. It would also be a good idea to cover the floor beams themselves with heat-insulating material, because they can serve as a kind of cold bridges.

When laying mineral wool, it is very important to protect yourself, and especially your respiratory tract, from insulation fibers. Therefore, you need to use a respirator, as well as gloves, goggles and long sleeves.

Waterproofing

We complete the insulation of the attic floor with waterproofing and subfloor installation

Due to the property of mineral wool to absorb moisture, waterproofing must be laid over the layer of mineral wool. This is also necessary if a concrete screed will be poured over the insulation.

If the attic is constantly used, a subfloor can be made on top of such a heat-insulating “pie”. Its role can be a concrete screed or OSB slabs. If the attic is practically not used, then you can simply lay boards on top of the existing beams. Then, if necessary, go up to the attic, moving around it will not create difficulties.

As you can see, insulating the attic floor is an accessible task, even for those who have never done it. You need to decide on the material for thermal insulation, although most often it is mineral wool. When installing a heat-insulating “pie”, it is important to remember the need for vapor barrier and waterproofing. This will allow you to achieve high results in insulating the attic floor.

Video: we discuss the floor structure in detail

Review of the structural details of the attic floor insulation device. What is a sufficient layer of insulation for a cold attic? What are the specifics of the work on laying thermal insulation for the attic floor?

When installing the roof of a private house, a space is formed between the roof and ceiling floors of the room, which is called the attic. It can be used as a storage room or a living room or office can be arranged there. In any case, it is worth paying attention to the insulation of the attic space in order to avoid heat loss and the safety of the wooden roofing.

Useful insulation

In practice, no construction innovation in the field of insulation can compete with mineral wool, which has already been proven over the years, which is ideal for insulating a country house. Due to the fact that mineral wool is made from hard rocks, its abilities reflect the thermal insulation properties of the stone. Meter-thick stone walls were replaced by brickwork. It has the following characteristics:

- thermal insulation;

- sound insulation;

- fire resistance;

- vapor permeability;

- environmental friendliness.

The thermal insulation coefficient of insulation is 0.038–0.045 W/Km, which is a rather low indicator. Thus, a protective layer of mineral wool with a thickness of 100 mm can be compared in terms of thermal insulation with brickwork with a thickness of 1170 mm. In this case, the sound insulation coefficient is 0.95 with a maximum value of 1.

Insulating a home with fiber insulation meets all fire safety requirements, since it does not burn at all and can withstand high temperatures.

For a wooden house, the vapor permeability of the thermal insulation material is also a very important indicator.

In this case, you cannot do without mineral wool. It has good vapor permeability and is used for installation of ventilated facades. And the last property of cotton wool is its environmental friendliness: the materials used in production do not have a harmful effect on humans and the environment.

If you plan to install mineral wool in the attic, then before starting work you need to decide on its type (glass wool, mineral wool, basalt slabs), the density of the material (varies in the range from 30 to 200 kg/m3) and the required quantity.

All this must meet the requirements for attic insulation.

Nuances for work

The floor in the attic is also the ceiling of the house, through which heat is lost from the room. Moisture from the warm air below constantly penetrates into the attic and has a negative effect on the fiber insulation.

When wet, it loses its thermal insulation properties, and with prolonged exposure to moisture it quickly collapses. The negative impact of moisture is also noted on the structural elements of the roof. Condensed water on the inside surface of the roof flows onto the rafters and beams. This leads to the destruction of supporting structures.

To protect mineral wool and the internal surfaces of the roof from water vapor, a vapor barrier made of moisture-proof material is used. It is laid between the ceiling and the insulation. It is important that the integrity of the waterproofing is not compromised.

To avoid further formation and accumulation of moisture in the attic, you need to properly organize ventilation. It is arranged through vents placed on the ridges and cornices, as well as through slatted and dormer windows. Ventilation will be quite intense if the ratio of the sum of the areas of the ventilation openings is from 0.2 to 0.5% of the attic area.

Isolation process

Working with insulating wool requires compliance with safety rules and the use of special PPE. If the attic space will not be used as a living room, then it must be made ventilated. Before you start insulating with mineral wool, you need to install ventilation gutters. They are attached under the roof with brackets to the roof frame.

If insulation is carried out using rolled material, then laying a vapor barrier is not necessary, since the wool is in a polyethylene cover. The mineral wool strips should be laid tightly and the edges taped.

In the case of using slabs, insulation is carried out on a pre-laid waterproofing coating.

You need to start insulating with cotton wool from the point farthest from the door, gradually moving towards the exit. If obstacles arise, the canvas or sheet must be cut, and in the next part of the insulation a cutout should be made in the shape of the obstacle. It cuts perfectly with a utility knife. If gaps appear, they need to be insulated with leftover material and scraps. Try not to be overzealous when compacting and bending the mineral wool, as this will negatively affect its heat-insulating ability.

If lighting fixtures are installed in the attic floors, they must be covered with special caps. Although the cotton wool does not burn, the device heats up during operation, and conditions may be created for the wooden floor to catch fire. Next, all that remains is to cover the thermal insulation by installing the floor in the attic. It can be plywood, plasterboard, chipboard or OSB board.

Arrangement of the attic

The roof of the finished attic has the appearance of a layer cake. Exterior covering is a roofing material designed to protect a home from precipitation. From the point of view of thermal insulation, it does not provide any effect. The upper waterproofing barrier is roofing material or a special film that is capable of retaining water, but is vapor permeable. It is laid in such a way that water flows through it to the outside. Next comes a layer of insulation, which forms a thermal insulation barrier.

The vapor barrier is designed to completely protect the installed insulation layer from moisture and steam. This polyethylene film is truly completely vapor and waterproof. Everything ends with a decorative coating to give aesthetic appeal and protection from mechanical damage.

The greatest difficulty in insulating an attic space is installing a waterproofing layer on insulation of a complex shape. The difficulty lies in bypassing all the load-bearing elements of the roof and organizing its exit under the roof to discharge water. It is very important here to maintain the integrity of the layer. The joints and fastening points must be taped, and secured between the rafters with staples or vertically nailed slats.

The insulation is placed tightly between the rafters and, together with the hydrobarrier, is secured with slats, which will later serve as a support for the finishing. It is recommended to insulate with mineral wool formed into sheets or slabs, since it is more resistant to caking and shedding during operation compared to rolled wool.

Final finishing

The material for the final finishing of the attic can be any sheet material that can protect the insulation from damage. Most often, plasterboard, chipboard or OSB boards, as well as wooden lining or plastic are used.

Installation is carried out on slats that secure the thermal insulation to the roof. You can assemble a separate metal frame from profiles, but this will require additional space in the attic and will once again compromise the tightness of the waterproofing.

Properly installed attic insulation will not only help conserve heat, but will also protect roofing and ceiling elements from premature aging.

August 27, 2016Specialization: Capital construction work (laying a foundation, erecting walls, constructing a roof, etc.). Internal construction work (laying internal communications, rough and fine finishing). Hobbies: mobile communications, high technology, computer equipment, programming.

If you live in an apartment building, then you have hardly ever thought about insulating the attic. Moreover, you would hardly have guessed that there was such a technical room in the building, unless, of course, you ran to the roof as a child.

However, in a village house or country cottage (which I am currently building for my son), the roof space plays a huge role. Often an open expansion tank of the heating system, ventilation pipes, and chimneys are installed there. And sometimes they equip living quarters - attics.

Therefore, I will not talk for a long time about how important thermal insulation measures are for this room, but will simply tell you how to insulate the attic of a private house using the example of my own son’s country house.

I think the technology described will be useful to everyone who is building or is planning to build a home outside the city with their own hands.

Materials for thermal insulation

Attics have been insulated for as long as I can remember. My great-grandfather and grandfather used hay and straw, sawdust and shavings for this purpose, and some in their village used dry leaves from trees.

Dad was already a more “advanced” builder and cold - in a private house and at the dacha he insulated the attic with expanded clay and old soldier’s blankets. By the way, expanded clay granules are also used in modern construction.

Now I will not tell you which option is better from the above, since I can offer more technologically advanced and effective thermal insulation materials for insulating the attic.

However, before this, I will note what technical characteristics must be inherent in the heat insulator so that it can be used for the described work:

- Light weight. The material after installation should not place a large load on the attic floor, roof trusses and load-bearing walls.

Otherwise, more durable building materials will have to be included in the project during construction, which increases the amount of the final estimate.

- Safety. The material used for insulation should not cause harm to human health.

Therefore, both the floor of a cold attic and the roof must be insulated with heat insulators that do not release hazardous chemical compounds into the air. Especially if you plan to arrange a living room there in the future.

- Easy to install. The less effort you need to spend on installing thermal insulators, the better, right?

In addition, there is not much space in the under-roof space of some houses, so it is not very convenient to work there. I always try to buy materials that do not require the use of complex equipment when laying them.

- Low thermal conductivity coefficient. The better this indicator is, the smaller the layer of thermal insulation material should be used. Accordingly, the internal space of the attic will not be reduced much.

Again, I think this is important, since I plan to make an attic in the attic at my son’s dacha. But I think you are not very interested in laying thermal insulation 20-30 cm thick.

- Hydrophobic properties. In attics, the air often has high humidity, which reduces the efficiency of the heat-insulating layer.

I advise you to choose materials that are either treated with water-repellent compounds, or those that do not change their technical characteristics as a result of getting wet.

- Fire safety. The roof is where there is a risk of fire due to improper installation or a clogged chimney pipe.

Therefore, when choosing a material, I would give preference to those varieties that do not ignite under the influence of open fire and do not support combustion.

Of course, I was unable to choose the ideal insulation that 100% meets all the listed requirements. But I’ll still tell you about those with whom I had to work.

So, I insulated the attics:

- polyurethane foam;

- polystyrene foam;

- mineral wool;

- expanded clay.

I'll tell you about them in more detail.

Polyurethane foam

The raw material for the manufacture of this heat insulator is plastic. Insulating an attic with polyurethane foam is a pleasure, but this requires special equipment. The fact is that the insulator is applied by spraying, for which compressors are used.

But you don’t need to buy screws, adhesive mixtures, lathing, and so on. And the polyurethane foam itself is applied very tightly, leaving no gaps through which cold air can penetrate into the under-roof space.

After hardening, the insulation becomes rigid, therefore it further strengthens the structure. The material has antiseptic properties; mold, mildew and other microorganisms do not multiply on its surface.

If you need to insulate a ventilation pipe in the attic, you can also use polyurethane foam. Just not sprayed, but in the form of ready-made shells with a protective layer of aluminum foil. They simply need to be secured to the pipelines using adhesive tape or plastic ties.

The biggest disadvantage of the material in question is its high price. However, if you consider the total cost of the work, you can save money, because additional hydro- and vapor barrier is not required in this case.

Styrofoam

This insulation, as well as polystyrene foam, which is similar in technical characteristics, is widely used for insulating rooms under the roof. I personally prefer polystyrene foam produced by extrusion. It is more durable, does not burn, has a low thermal conductivity coefficient and is not damaged by rodents.

The cost of insulation is quite affordable, and anyone, even the most inexperienced summer resident, can install it in the attic. Polystyrene is processed with hand construction tools and secured with dowels.

Mineral wool

Fibrous heat insulators are a universal material. Mineral fiber-based insulation comes in rolls, slabs, in the form of a dry mixture, and so on. They are perfect for insulating attic floors and roofs.

The basalt fiber from which mineral wool is made has a very high melting point. Therefore, this insulation can be used for installation on chimneys, the surface of which can become very hot.

There is one point here. The insulation is not waterproof and can lose its heat-protective properties when wet. To avoid this, when insulating, it is necessary to install hydro- and vapor barrier membranes. Or buy those varieties of mineral wool that are treated with special water-repellent compounds.

The bottleneck of some types of mineral insulation is environmental friendliness. In the manufacture of basalt mats, a certain amount of formaldehyde resins is used, which can be harmful to human health. Especially during the installation process.

Expanded clay

Granules of this material, as I already told you, were used by my father when insulating his first dacha. Expanded clay has a low thermal conductivity coefficient and weighs little. However, it is free-flowing, so it can only be used to insulate the floor of the roof space.

But the installation process itself does not require any tricks. You just need to pour it on the floor, and then protect it well from moisture with a moisture-proof membrane. If you are going to later equip the attic, you can cover it with a screed on top, and then lay a decorative covering.

Do-it-yourself insulation of the attic space

We’ve sort of decided on the most popular thermal insulation materials, now I’ll tell you how to properly insulate the under-roof space so that you can build an attic there in the future.

Let's deal with the question of how to lay insulation under the sheathing, because this method will allow you to stuff your chosen decorative material on top without any problems.

In my son’s attic, I decided to use mineral wool, but I’ll tell you right away about polystyrene foam, since the working technologies are similar, and foam plastic is easier to work with if you are a novice builder.

The entire insulation process consists of several stages:

- Preparation;

- waterproofing;

- laying the heat insulator;

- vapor barrier;

- arrangement of sheathing and installation of decorative cladding;

- insulation of utilities;

- floor insulation.

I'll tell you about each stage in more detail.

Preparatory activities

Let's start, as usual, with preparation, because it is unlikely that your attic is already ready for construction work.

After all, in almost 100% of cases this room is used as a trash storage facility, where all unnecessary things are demolished (and sometimes taken from the apartment). The attic of my son’s dacha was clean, since the house was new, but in my home, while clearing out the rubble, I found old books, clothes, several family heirlooms (which my wife did not consider such) and much more.

In addition, if you have tried to insulate before, I advise you to get rid of all traces of this process. For example, remove sawdust, scraps of felt, construction debris, and so on from all crevices. Believe me, I have insulated attics more than once and I know how important it is.

By the way. And drive away all the spiders from the attic, and then clear the room of cobwebs. After all, you will be building an attic for yourself or your children, and not for any insects.

Last moment. Bring the necessary tools into the attic and provide lighting. It’s unlikely that you have sockets there, so you’ll have to run an extension cord with a light bulb. Although these measures seem obvious to you, since I had to return to the city for an electric one, since not a single extension cord at the construction site reached from the distribution panel to the attic.

Waterproofing

A waterproofing membrane is needed in order to protect the thermal insulation layer itself and the room under the roof from excess moisture. This is especially important if the roof was laid a long time ago (for example, you are insulating the attic of an old house) and the roofing materials used are not the most modern.

The moisture-proof film is installed directly on the rafter structure. It needs to be stretched and overlapped so that after finishing work a sealed layer is formed. You can fasten the material with a construction stapler with staples.

Laying insulation

Thermal insulation material, as I already said, must be mounted on a pre-assembled sheathing. However, if you want to save a little money, there is no need to construct a separate frame. Its role will be perfectly played by the roof rafter system.

In the latter case, in order to press the material and be able to install decorative sheathing, you will only need to install a light counter-lattice at some distance from the surface of the heat insulator. Then you will get a small ventilation gap that removes excess moisture from the insulating layer.

So, the scheme of work for laying insulation is as follows:

- Mineral wool rolls must be cut so that their width matches the distance between the rafter supports. After this, lay it under the roof surface, gluing it to the surface or temporarily securing it with wooden slats.

- To make installation easier, you can use mineral mats. Their width should be slightly greater than the distance between the rafters, so that after installation they will snap into place and not fall out.

- The foam must be cut as accurately as possible so that it fits closely to the installation site. The gaps between the insulation panels will greatly reduce the effectiveness of insulation measures, so they need to be filled with foam.

Vapor barrier

After laying the insulation, you need to install a vapor barrier membrane. It will protect the insulating material from penetration of moisture generated during human activity.

For vapor barrier, special films are used that prevent the heat insulator from getting wet, but do not prevent air infiltration through the enclosing structures. As a result, a microclimate that is comfortable for living will be formed in the attic, if you look at it from the point of view of humidity.

So, after installing the insulation, it is necessary to attach a vapor barrier to the rafter supports (which act as sheathing). This should be done using a stapler, carefully pulling the film.

The edges of the material overlap each other to prevent the mineral wool from getting wet. To further insure yourself against surprises, I recommend sealing the seams with adhesive tape.

Vapor barrier films allow air to pass in only one direction. Therefore, before installation, make sure that you have turned the membrane to the desired surface.

Counter-lattice

Having finished with the films, you can begin to complete the finishing operations of the walls (or the roof, depending on how you look at it). I will use for this, but in the same way you can fasten OSB boards, drywall, lining, and so on.

Here, too, there is an opportunity to significantly save on the purchase of materials and reduce the time for carrying out all work. The fact is that the main parts of the sheathing will be powerful rafter legs, and all you have to do is make cross members that will serve as additional stiffeners for the sheathing.

The material for the transverse frame can be a wooden strip or galvanized profile. The essence will not change. The parts just need to be screwed from above to the rafters so that they are located at right angles to them. The step between adjacent elements depends on the decorative finish; I made it 30 cm so that the cladding does not sag under load.

The decorative finish itself also depends only on your imagination. I'm going to glue the wallpaper on top for now to save money, and then I'll come up with something more beautiful. You can do the same.

Just before gluing the wallpaper, do not forget to putty the seams between the sheets of plywood and perform other necessary operations (primer, etc.).

Insulation of utilities

If you do not plan to create an attic, you definitely need to insulate the ventilation ducts in the cold attic, as well as, if there are heating, water supply and smoke exhaust pipes (the term you came up with).

Of course, you can use mineral wool for this, wrapping it around the pipes, wrapping it with roofing felt and securing it with wire. But why complicate your life if you can buy ready-made shells for pipes of the required diameter (made of polyethylene foam, polyurethane foam, polystyrene foam, and so on). They just need to be snapped onto the pipe and secured with tape to be sure.

The cost of such insulators is low, so you definitely won’t go broke.

Insulation of the attic floor

The floor is a horizontal surface, so it can be easily insulated with bulk material. For example, expanded clay. But since I started working with mineral wool (foam plastic), I won’t buy expanded clay, I’ll limit myself to what I have at my disposal.

So, the attic insulation technology is as follows:

- First you need to clean the surface of dust, accumulated debris, foreign objects, and so on.

- Then install the support joists. I make them from wooden blocks with a section of 20 by 10 cm. You can select the height of the logs based on the thickness of the thermal insulation material you have.

- The entire surface is covered with a layer of waterproofing. Be sure to ensure the tightness so that the mineral wool does not get wet, as this may affect its technical characteristics.

- Cotton wool is placed on the waterproofing layer. Choose a material that is specifically designed for insulating horizontal surfaces. For example, Izover KT37.

- The vapor barrier membrane is again stretched on top, onto which the facing material is stuffed. I used plywood, which I plan to cover with linoleum.

If you do not plan to use the attic as a living space, then you can not insulate the roof, but only insulate the floor. In this case, you need to pay attention to some features:

- Wood for joists and cladding must be treated with hydrophobic, fire-retardant and antiseptic compounds to maximize its service life.

- For entry, it is better to use an insulated hatch to the attic, since it is this structural element that is often the source of large heat losses.

Now we can say with confidence that the insulation of the floor (or ceiling from the cold attic side) has been completed in full. And in order to achieve maximum efficiency of thermal insulation measures, I still advise making an insulated hatch with a ladder, as described in the video in this article.

Conclusion

As you can see, there is nothing scary or difficult here. If you liked the material or have any questions, you can ask them in the comments. I would also be grateful for stories about how you insulate the attic in a private house with your own hands.