Gates accordion entry scheme. Automatic garage doors with remote opening: which ones to choose? Making entrance swing gates with your own hands

Buy a good garage structure in our time - the pleasure is not cheap. Do-it-yourself garage doors are cheaper to make, but certain knowledge and skills are required. It is also desirable to have welding skills. Therefore, how to make a garage door with your own hands is a question that needs to be thoroughly understood. And then it will be possible to start the task at hand.

Near a private house

Most users choose them for their compact size.

Advantages: convenience, protection against hacking, universal in use. Flaws: high price, folding structures are prone to damage.

swing gate

The photo shows a swing version of the design.

In the suburban area

Sliding gates

Rollback option

Overhead gate

These are the most practical and convenient vertical designs. When opened, the sheet of metal rises up and lies horizontally in the form of a visor. The design of such a mechanism is simple. The canvas is attached to the frame and moves around the axis, changing the horizontal position to the vertical one. Folding gate convenient in operation.

lifting structure drawing

Advantages: resistance to corrosion and burglary, do not require additional space.

Feature Comparison

Guided by the indicators in the table, we can say that the choice is only for the buyer. It all comes down to cost and reliability. For example, swing and sectional models are good to install in a home garage, but they are not suitable for garage cooperatives, as they have a low degree of reliability.

Up-and-over garage doors are suitable for any building, but their main drawback is their high cost. Due to the low price, swing gates are suitable for a private garage. If necessary, they can be insulated, automated and reinforced with an additional sheet of metal. In addition, it is not difficult to weld garage doors at home.

Frame device diagram

The frame is made from metal corner, which is welded around the entire perimeter of the doorway. Thus trim the slope inside and out. Between themselves, the inner and outer corners are welded with metal strips in several places. You should get a frame frame.

After the frame is ready, collapsible hinges are welded on the sides. The lower part must be connected with an outer corner, and the upper part with a frame frame. This design is also suitable for a garage from

With the development of construction and production technologies for private households, new ideas and designs come, devices appear that were previously used only in the industrial sector and objects of national importance. We are talking about a very interesting retractable gate system that saves the owners from having to open and plow inconvenient swing doors of classic designs.

We choose how to make a gate only with our own hands

In addition to inconvenience in handling, bulky sashes swing gate ny structures "eat" a decent piece adjoining territory or spaces in front of the gate. If there is not enough free space in the yard, it makes sense to build a gate with your own hands according to one of the most compact and easy-to-use schemes:

- Entrance gate in the form of a retractable structure. At proper planning schemes and devices of the sliding panel, such a system will take a minimum usable space site;

- Folding or sectional systems. According to the device, such structures resemble a screen or horizontal blinds.

For your information! All of the above options are much more difficult to assemble and install the gate with your own hands than the classic two-leaf swing gates.

The installation of retractable systems requires a high assembly culture and careful fitting and adjustment of all components, but the benefits obtained more than cover the time and effort spent.

Retractable structures are divided into cantilever schemes and roller gates on wheels. While superficially similar, the systems are structurally different in the way they support the front edge of the movable panel.

In cantilever versions, the leaf hangs "in the air" during the entire time of movement of the moving part of the gate structure, from the moment of contact with the roller catch of the lock on the pole. As a rule, low and light cantilever gates with a small overhang of the movable panel are built according to this scheme.

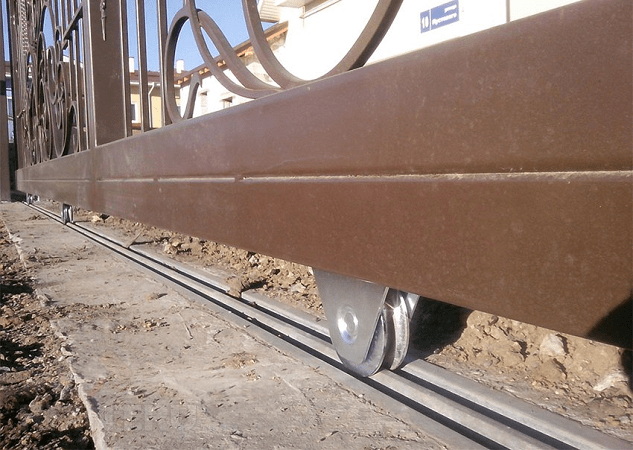

Roller options are made according to the scheme with a supporting wheel mounted on the lower beam of the moving part of the gate. The use of a wheel makes it possible to make the blocking panel arbitrarily massive and high, but at the same time it will be necessary to regularly clean the guide support bar laid in concrete base. Most often, sliding roller wheel schemes are used for passage with a width of more than four meters, for example, a territory industrial facility or a car park, where trucks and construction equipment constantly runs.

For the home version of the sliding gates are more suitable cantilever structures, easy to manufacture and reliable to use.

We build cantilever gates with our own hands

The design of cantilever gates is based on the standard principle of "latches". In fact, the whole structure consists of four nodes:

- Movable panel mounted on a guide bar;

- Brick or metal pillars and a fixed gate or fence panel, forming a "pocket" into which the movable panel and drive are removed;

- System of clamps and guides along which the door panel moves;

- An electric motor with sensors for the position of the movable sash and locking mechanisms.

Important! The device of cantilever gate structures is no more difficult than any other types of gates, but before assembling it with your own hands, you should understand the device of industrial cantilever systems.

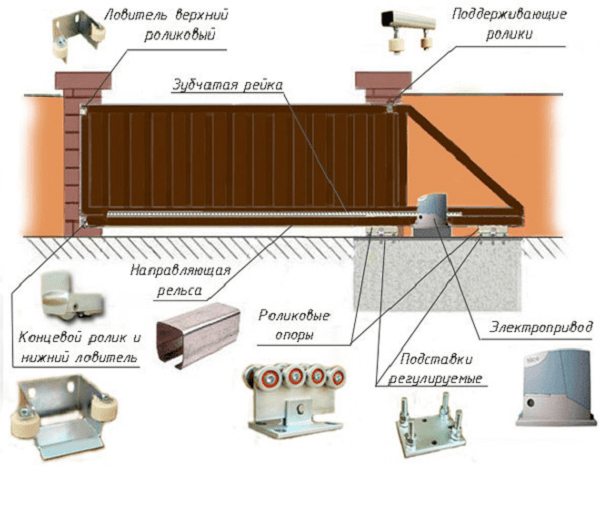

Features of the gate device

The most important part of the cantilever gate design is the electromechanical drive, consisting of an electric motor with a planetary gear and a drive gear, and gear rack fixed on the lower bearing beam of the movable panel. The entire drive structure is mounted on a massive concrete base reinforced with a steel bar. Often, the design of the drive with a concrete "cushion" is brought closer to the "pocket" of the gate, so as not to interfere with the movement of the car.

The movable part of the structure is made in the form of a panel or frame mounted on rollers. When a signal to close is given, the electric motor drives the toothed bar through the gearbox, and the panel smoothly leaves the gate “pocket” along the roller bearings until it comes into contact with the traps located on the opposite side.

We build the base and supports for cantilever gates

The design of the base of the cantilever gate is somewhat different from the usual swing or folding schemes. The whole device is divided into two main parts: the control and the receiving. The design of the first half includes a fixed part of the gate or fence, which forms the so-called "pocket" with an electric drive, a columnar support and guide rails - a place where the movable panel enters when the passage is opened. The second part is a pole with stops-clamps. Its function is to capture and fix the panel in a fixed state.

The specifics of the operation of the gate structure requires the manufacture of a powerful concrete base under the first half, compensating for the overturning moment that occurs when the wings are opened. For this, a concrete pad is made, reinforced with a steel bar, at least one and a half meters deep and about two meters long, as shown in the diagram and photo.

When pouring the mortar into the concrete base of the pillow, it is necessary to lay the embedded element made of channel No. 20 with reinforcing posts. After that, vertical bearing pillars can be laid out of brick or cast from concrete to the height of the future gate structure. During the construction of pillars with inside reinforcing metal plates are laid.

Installation of wiring and welding of the cantilever gate frame

For the normal functioning of the gate, the structure will need to be supplemented signal system and a circuit of two photocells that control the position of the movable gate leaf in the closed and open state. The wiring must be laid according to the diagram shown in the photo.

A little more complicated than laying the wiring is the manufacture of a movable frame with a balancer. The frame drawing is shown below. The frame of the movable panel is welded from a profiled pipe 60x40 mm according to the specified dimensions. To increase the rigidity of the frame, a tubular profile of a smaller section of 30x20 mm is first welded inside along the perimeter of the pipe, and diagonal struts are installed. How to make a roller support can be found in the video:

In some cases, experts recommend making a movable panel on the gate from a corner with your own hands, and then scalding it with a thick profile of 60x40 mm. In this case, a ready-made mating plane is obtained on the frame from the shelves of the corner, on which it is easy to fix the cladding made of corrugated board or sheet iron.

After welding, the frame is subjected to sandblasting or emery, treated with an anti-corrosion compound and painted with automotive enamel to match the color of the gate and fence. In the lower and upper parts of the pillar, you will need to install locks on the gate with your own hands, on which the shackles for padlocks are attached. At the same time, experts recommend equipping the upper lock with a latch, and hanging the lock on the lower stopper. The upper lock is relatively easy to open with your hands, but it is almost impossible to reach the lower lock from behind the fence.

Do-it-yourself accordion gate

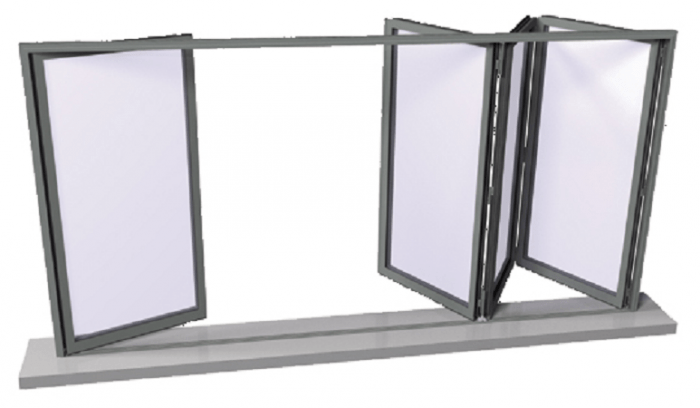

If there is not enough space on the site to install conventional swing or modern sliding gate systems, you can use original design folding or sliding gate. Both options allow you to save as much space as possible inside the site and the territory in front of the passage, which is especially important if the carriageway passes almost close to the gate.

The design works on the principle of an accordion - interconnected door hinges separate panels.

Each panel is a welded frame made of a profiled pipe measuring 60x20 mm or a corner with a shelf width of at least 50 mm. On the upper and lower end surfaces of the frames, guide pins or axles are welded, with the help of which the panels are installed in two guide rails of the gate opening.

Panel frames are made by welding on a conductor box knocked down from boards. Thus, it is possible to achieve the maximum match of all panels in size and shape. It remains to connect the panels with door canopies and install on the guide rails.

One of the panels, most often the extreme left or right, is made in the form double frame. This is done to hang the doors of the gate, as in the photo. For this, first on inner surface profiled pipe of the frame, door canopies are welded, after which the wicket frame welded in advance is installed and the location of the mating halves on the door frame is fixed.

The frames of sections or panels are most often lined with corrugated board or polycarbonate, the material does not fundamentally affect the operation of the gate. It remains to paint and install constipation.

Conclusion

Like all complex drive mechanisms, sliding gates require constant care and maintenance. If the jammed drive of swing gate structures can be simply turned off and the leaves manually opened, then for retractable, especially heavy wheel-roller systems, manual opening without additional mechanisms is quite difficult.

When you are about to buy a folding gate, there are only a few basic things to consider in order to make the right choice. First of all, these are the dimensions of the future design. Do it yourself correct measurements quite difficult, there is always a risk of making a mistake, so it is better to call a specialist for this. Typically, companies offer measurements to be performed free of charge, which is doubly beneficial for the client.

We also recommend that you study the main advantages of existing structures and already proceed from what goals you are pursuing. It is important that products meet the required level of strength, reliability and durability. Not less than important point– choice of automation. It must withstand the maximum load level in your case, and also serve for a long time. Depending on the budget, you can choose both imported and domestic brands. This is already enough to pick up a high-quality accordion-type system, and experts will advise you about everything else.

We will send the material to you by e-mail

WITH significantly increase the comfort of operation of automatic garage doors with remote opening from the remote control. However, the existing designs of garage doors have different budgets for the construction and operation of these communication systems. In principle, the opening mechanism can be mounted on both roller shutters and hinged sashes. In the latter case, the resource decreases, operating costs increase.

Types of garage doors

To choose an automatic garage door with remote opening for your own needs, you need to study existing designs. Most often, several types of gate leaves are used:

- hinged - until recently considered a classic, two canvases open on hinges, the maximum angle is 180 degrees;

- sectional - consist of hinged panels that crawl up under the garage ceiling when opened;

- roller shutters - the design is similar to the previous version, however, the panels are very narrow, which allows them to be wound on a drum rigidly fixed above the garage opening;

- lift-and-turn - the canvas is one-piece, moves when opening along a complex trajectory in two planes;

Lifting and turning canvas - a fairly rare type

- folding "accordion" - the canvas is made of several vertical wings, movably fixed relative to each other, usually opens in two directions, the panels are placed perpendicular to the opening near the bearing walls;

Gate type "folding accordion"

- sliding - are used only in industrial garages or in the areas of private owners, they usually have one long sash that slides off along the wall.

Each structure can be equipped with an electric drive to move door leafs from home, car interior.

Related article:

The principle of operation of the system, schemes

Due to the variety of designs of operators, automatic garage doors with remote opening should be designed before building a vehicle storage building. This will save you from alterations, making changes to the power frame of the building. However, the need to automate the process of opening the valves may arise during the operation period. Therefore, it is necessary to consider all existing options.

swing gate

When operating, designing swing leaves of automatic garage doors with remote opening, several drives can be used:

- underground - Bottom part the gate is attached to the drive, the upper one hangs on a standard hinge, the performance of the system depends on the alignment of the hinges, the installation is extremely difficult for an amateur;

- linear - installed indoors in the opening, actuated by a contact switch or remote control, suitable for sashes weighing up to 3 tons;

The advantage of these designs is the use of existing garage canvases, which somewhat reduces the initial investment.

There are many more disadvantages of automation schemes for swing doors:

- when choosing an underground mechanism, it will be necessary to concrete the pit, seal it to avoid water accumulation;

- the doors open outward, so it is necessary to clean the adjacent territory, the presence free space;

- the windage of the gate is maximum, therefore, restrictive chains are used to prevent spontaneous opening, drive failure.

However, hinged canvases are usually made of sheet steel, so vandal resistance and building safety are higher than other existing options.

sliding gate

Unlike existing structures automatic sliding gate for a garage with remote opening, they are most often equipped with a ground rack and pinion mechanism. A worm rack with teeth is fixed on the sash, a gear is put on the electric drive pulley, which moves the structure. So there's always enough underneath big gap, which must be sealed with corrugation, rubber, and other methods.

A significant disadvantage is the movement of the long structure sideways. Therefore, such gates are used with a sufficient width of the facade of the building. Instead of a rack and pinion drive, chain modifications can be used, but they are noisier. To increase the resource top part sashes are often hung on an additional traverse.

Overhead gate

In the absence of free space under the ceiling of the room (ceiling), sliding modifications cannot be installed. Therefore, the car owner chooses a lifting and turning panel, which can be made independently according to frame technology(styrofoam inside the bars) or from a sandwich. Spatial rigidity, geometry stability is higher here, there are no articulations of panels.

However, there are side guides, rollers along the edges of the web. Transformation mechanism, mounting scheme individual elements the most complex of all existing drives. Measurements will have to be made repeatedly; if the builders make mistakes, it is necessary to correct the geometry of the opening. Therefore, it is better to order the installation of a specialist m.

Important! It is very difficult to install a built-in gate in a lifting and turning canvas. The cables occupy almost the entire rear surface of the panel at the bottom.

Related article:

Sectional doors

The most popular for automating the process of remote opening are sectional structures. The electric drive scheme is necessarily duplicated by torsion springs for manual operation. Self installation difficult but accessible home master- each product is accompanied by detailed instructions.

The advantages of sectional structures are as follows:

In the event of a power outage, the gate leaf can be lifted manually. However, the presence of a minimum lintel is a prerequisite for installing the system.

Roller shutters (roller shutters)

Steel, aluminum long panels-lamellas make up a roller shutter, which is wound on a shaft inside a special box, both with manual and mechanical actuation of the system. Therefore, it is enough to mount an electric drive at the end of the shaft in order to fully mechanize the process, leaving the possibility of manual control of a metal vandal-proof curtain.

Roller shutter motor

The benefits are in budget price, quick installation, saving the roadway, the tightness of all nodes with special elements. Roller blinds are highly maintainable, curtains can be replaced if necessary, a new interior of the facade of the building. The drive mechanism does not need to be removed.

Folding gates "accordion"

Private owners of "accordions" from vertical folding sections are used very rarely. Drives for automating the opening process are completely similar to swing structures, with the exception of underground electric motors with levers.

The disadvantages also lie in the need for free space in front of the front facade of the building, cleaning the adjacent territory. Casements are made of sandwiches, polymer panels, windows, gates, ventilation ducts are built into them. Structures with minimal load bearing walls because they are light in weight.

Save Time: Featured Articles Every Week by Mail