Ion exchange resin for water softening principle. Ion exchange resins: application. How effective are they in water purification? See what “Ion exchange resins” are in other dictionaries

A common problem faced by most residents of large cities is the quality of drinking water.

Yes, it’s not very often that dirty, rusty water flows from taps, or liquid that stinks of hydrogen sulfide, but this is a pressing issue, and without the proper level of water treatment, using such water for drinking and domestic purposes is problematic for a number of reasons.

Hard water that has not gone through the stage of purification and softening causes significant harm to your water heating devices - washing machine, dishwasher, electric kettle. When working with hard water, these devices will fail much earlier than the manufacturer intended for normal conditions operation.

This is explained by the fact that a layer of scale forms on the heating elements, which provokes accelerated corrosion of the metal.

1 What is the technology for softening water using ions?

Most effective way Today, water softening is carried out using the ion exchange method. When treating water using the ion exchange method, it is possible to operate as efficiently as possible. It’s not for nothing that this method of water treatment is so popular both in everyday life and in industry.

As you know, water hardness is caused by calcium and magnesium salts dissolved in it. The essence of the ion exchange method is that certain chemical reagents, which are called ion exchange material, or simply ion exchangers, tend to regulate the ionic structure of water in the desired direction.

This allows you to replace mineral hardness salts with other chemical structures that do not impart undesirable properties to water.

To perform water treatment using this method, special filter installations are used that are filled with ion exchangers through which water is passed.

When hard water penetrates through an ion-exchange material, most of the electrolyte ions dissolved in it are replaced by the same amount of ion-exchange ions, resulting in a change in the chemical structure of the water itself and the chemical reagent.

1.1 Pros and cons

2 Equipment required for work

The technical features of the equipment, as well as its price, depend primarily on the scope of its application: filters for Wastewater can be enormous in size, while devices for household use have fairly compact dimensions.

As for prices, the minimum cost of a device for home water treatment is at least $300.

Today, all ionic softening filters are available in two main form factors:

- Small stationary filters with a replaceable cartridge;

- Ion exchange columns are large, plumbing-connected devices that generally have an automated resin recovery process.

Column-type filters have the following configuration:

- Working capacity - made in the form of a sealed tank or cylinder, which is filled with ion-exchange resin;

- A valve with an electronic processor that controls the water supply;

- Container for restoration material - basically has the shape of a tank into which salt is poured.

The operation of such softening devices is fully automated: the processor supplies water to the column, which, entering the ion-exchange medium, releases ions of hardness salts to the resin, after which the water, already purified, is supplied through the outlet hose to the water-consuming devices.

When the ion exchange resin is depleted and needs to be regenerated, the device injects a small amount of liquid into the reagent tank, which, after being saturated with brine, is returned back to the resin. Circulation continues until the system is completely restored.

In general, water treatment columns household use and industrial devices for filtering wastewater, differ from each other only in size working capacity and the type of reagents used.

2.1 Recovery of ionic resin in the cartridge

In filters with cartridges, resin restoration is carried out manually, this is done as follows:

- The water supply to the filter is shut off and the internal pressure is released.

- Remove the resin cartridge.

- We clean it of dirt by rinsing it under running water.

- If the cartridge is disassembled, then the resin is poured into a separate container and covered with saline solution; if not, then the entire cartridge is lowered into it. Brine We make it at the rate of 100 grams of salt per 1 liter of water. We will need approximately 2-4 liters of liquid.

- Leave the resin in the solution for 6-8 hours, then drain it and rinse the resin with clean, pre-filtered water 2-3 times.

- The cartridge is being installed in its original position.

- In the first liters of water passed through the filter, after the resin has been restored, you may feel a slight taste of salt - this is normal; it will disappear within half an hour.

The operating efficiency of ion exchange filters will be maximum if the certain rules according to the quality of the supplied water:

- The liquid must not be contaminated with microbes.

- Prohibited from high content active chlorine and hydrogen sulfide.

- Optimum temperature of treated water: 5-40 degrees Celsius.

- Flow pressure: 2-7 kgf\cm2.

- Concentration mechanical contamination should not exceed 1 mg/l.

2.2 Operating principle (video)

Ion exchange resins are small translucent spherical granules. The color of the resin granules generally depends on the composition of the resin: for example, strongly acidic cation exchange resins are bright yellow or brown, while weakly basic anion exchangers are white, opaque granules. The main application of ion exchange resins is the removal of hardness in water treatment plants for energy enterprises. Ion exchange is based on the removal of ions from water passed through a layer of resin, which replace sodium cations, protons or hydroxyl groups located on the active groups of the resin.

Resins differ both in their principle of action (cation exchange, anion exchange) and in their structure (gel, macroporous). The choice of a particular resin for a particular process is determined by the nature of the impurity removed from the water.

Classification of ion exchange resins

1. By composition. There are anion exchangers and cation exchangers. As their names suggest, cation exchangers have a cationic functional group, and anion exchangers have an anionic one. Accordingly, cation exchangers exchange (and extract from water) cations, and anion exchangers exchange anions.

2. By type and strength of functional groups and degree resins are divided into:

Strong acid cation exchange resins - used for water softening and desalination.

Weak acid cation exchange resins - used to eliminate temporary hardness, as well as high alkalinity of water.

Strong basic anion exchange resins are mainly used for desalination of water with a very high salt and silicon content, which is caused by high speed exchange of strong base anion exchangers. This method is superior in speed and energy consumption reverse osmosis.

Weak base anion exchange resins are most often used for desalting organic compounds, including sucrose, whey, glucose and more.

Apholytes have several types of functional groups (anionic and cationic) in different or equal proportions in one resin - they are mainly used for desalting water in one step. The ratio of certain functional groups is determined by the ratio of the removed ions in the source water.

3. According to the structure of granules: polystyrene, gel and macroporous. Mixed structures such as polystyrene-gel and polystyrene-macroporous are also possible. Can be used to purify water from lime.

Gel-type resins, when in contact with water, swell more than others, at which time their volume increases by one and a half to two times. Ion exchange in gel-type resins occurs quite quickly, but in speed these resins are definitely inferior to resins with a macroporous structure, which, unlike gel resins, do not swell as much.

4. According to the exchanged ion in its original form: sodium, hydrogen, etc. Most often, in the original form of the resin, the exchanged cations are sodium or proton for the cation exchange resin, and chlorine or a hydroxyl group in anion exchangers.

5. According to the degree of uniformity of granule sizes There are monodisperse (most of the granules have the same size) and polydisperse (the size of the granules is distributed over a wide range).

To regenerate ion exchange resins, the following are used: regeneration salt (for resins in sodium form), acid (for resins in H-form), sodium hydroxide solution (for resins in OH-form).

Since the quality of drinking water is getting worse every decade, scientists invented an ion exchange resin or anion exchange resin back in the 60s of the last century. This substance is a polymer that is very small in size. They are produced in the form of balls with a diameter of up to 1 mm. On appearance this material resembles beluga caviar.

By its nature, this substance is insoluble; it can easily enter into exchange reactions with ions of other solutions. Also, some types of ion exchange resins can provoke the process of oxidation and sorption.

The main document that regulates the quality of these substances is GOST 20301-74 “Ion exchange resins. Anion exchangers. Technical conditions".

The principle of operation of the substance

The principle of the main operation of filters with ion exchange resin is aimed at purifying and softening hard water, that is, water where the amount of heavy metals is increased. Balls of special polymers of this resin initially contain “free” ions. These particles have the ability to trap ions of other substances.

When the ion exchange resin interacts with another liquid, its particles begin to swell. The balls can increase in size up to 4 mm.

In production, water purification plays one of the most important roles. Therefore, large filters with ion exchange resins for water were used in the past. Water must pass through several stages, since the filter consists of several layers: main, exhaust and fresh. On each of the filter layers, water releases heavy metal ions and harmful substances. For continuous cleaning and efficiency of filters, it is recommended to change them at least once every 4-6 months.

Basic properties of ion exchange resin

When purification occurs with an ion exchange resin, the water loses:

- . harmful chemical elements and their connections,

- . particles of potassium and magnesium, substances that can form scale,

- . heavy metals, etc.

Ion exchange resin Water softening can significantly reduce its hardness. Therefore, the use of such a filter in living conditions will help:

- . remove scale from plumbing fixtures and heating elements in a kettle, cauldron or geyser,

- . reduce hair fragility, dry skin, flaking,

- . relieve or reduce scalp irritation, remove dandruff,

- . descaling electric heating elements will help reduce electricity consumption,

- . reduce the use of detergents by up to three times,

- . remove bluish deposits from faucets and taps in your home.

The use of ion exchange resins in everyday life is quite safe, since these substances are non-toxic. They are not capable of spontaneous combustion or explosion. Cartridges with these resins are installed in front of heating devices, for example, in front of a water heating boiler, boiler or instantaneous water heater.

To ensure that filtered water reaches the entire house, the filter is installed together with carbon filters. In this case, a three-stage purification degree is used.

Production of ion exchange resins

Ion exchange resin for water softening is obtained as a result of two chemical reactions. It is susceptible to polymer-like transformations and the polymerization process.

To obtain this substance by polymerization, special monomers are used that contain ionic groups. And for polymer-analogous transformations, these particles are directly introduced into inert polymers. Manufacturers of ion exchange resins also make this material using the polycondensation process. But such an ion exchange resin has lower quality characteristics.

To produce cartridges with ion exchange resins, the polymerization of three substances is used:

- . styrene,

- . acrylic acid derivatives,

- . vinylpyridine.

Application

As has already become clear, ion exchange resin is a substance that can significantly improve the quality characteristics of water. Purified water becomes completely safe for human health; it does not leave scale on appliances, which allows you to save on electricity and the purchase of new household appliances.

The characteristics of the ion exchange resin allow it to be used both in everyday life and in large production companies. They are used in:

- . Food Industry,

- . pharmacology,

- . medical industry,

- . chemical industry,

- . heavy industry,

- . everyday life

Filters with such cleaning materials use:

- . in boiler rooms,

- . during the production of bottled waters, low-alcohol drinks, beer and vodka products,

- . at sugar factories,

- . at nuclear power plants.

Features of packaging and storage

According to GOST 20301-74, ion exchange resins must be packaged in plastic bags, having previously been packaged in vinyl leatherette bags. Permissible weight one sealed bag can be 50 kg. It is also permissible to package these substances in propylene cans or containers.

It is worth noting that during transportation or storage, the proximity of cation exchange resins to anion exchange resins, as well as any oxidizing agents or solvents, is not allowed. This product can only be stored in dry and well-ventilated areas where the air temperature will not be lower than +2°C. Bags with ion exchange resins can be stored at a distance of 1 meter from heating devices. The shelf life is 12 months from the date of production.

The price of ion exchange resin in Russia is quite different, but average cost This cleaner costs 120-150 rubles per liter.

Each manufacturer sets its own price. For example, one of the most popular brands are considered:

- . Purolite,

- . Lewatit.

The price of a 25 kg bag of Purolite ion exchange resin is 6,500 rubles, 25 kg of Lewatit ion exchange resin will cost a little less - 4,640 rubles.

To provide high level To purify water at home, you must use a three-stage filtration system. This system includes a cartridge mechanical cleaning, softening (which uses an ion exchange resin) and post-treatment from activated carbon.

The resource of such cartridges is approximately 5-7 thousand liters, so it is enough to replace them once a year with new ones. But there is one important point: the effectiveness of a cartridge with an ion exchanger directly depends on the level of hardness of the incoming liquid and its full use is only possible with regular regeneration.

Ion exchange resins: general description

These are compounds in the form of small balls, usually amber in color. They are able to capture magnesium and calcium ions from aqueous solutions and replace them with sodium (or hydrogen) ions. As a result, the liquid acquires a normal level of hardness.

Such materials have been widely used in water treatment processes since the 60s of the last century. This is one of the affordable, environmentally friendly and quick ways filtration. It allows you to get rid of scale and achieve good foaming upon contact with detergents and get drinking water without foreign impurities.

In household filters, gel-type ion exchangers are most often used (for example, KU-2-8 cation exchanger, Dowex, Relite, Lewatit, etc. They have chemical resistance, osmotic stability and do not release harmful impurities into the purified water.

Since the capacity of ion exchangers is limited, it is necessary to restore it in a timely manner. To do this, the ion exchanger is immersed in a solution containing excess sodium ions. In this case, the process will go in the opposite direction: sodium ions are absorbed, and calcium and magnesium ions are released into the solution. Table salt is usually used as a regeneration compound.

How to regenerate resin using table salt?

To do this, close the inlet tap to shut off the water supply to the filter, and turn on clean water to relieve pressure in the system housings. Then you should take out the mechanical cleaning cartridge and thoroughly clean it of dirt by rinsing it under running water with a brush, and also wash the filter flask. After these procedures, install the mechanical cleaning cartridge in place.

Then you need to get the cartridge with the ion exchanger. The procedure for its regeneration depends on the type of filtration system: in simple filters the contents can be poured out and regenerated in a separate container, in more complex filters the restoration is carried out without removing the granules.

In the first case, pour 2 liters of a 10% solution of non-iodized table salt into the resin (100 g of salt per 1 liter of water) and let it brew for 6-8 hours. After this, the ion exchanger is washed clean water 2-3 times and go back to sleep.

The second option involves pouring resin directly into a 2 liter cartridge of 10% saline solution, after which the cartridge is placed in a washed flask and another 0.5 liter of solution is poured in and left for 8-10 hours. After this time, the liquid is drained and the ion exchanger is again immersed in 2 liters of solution. To eliminate excess salt, the granules are then washed with 2 liters of clean water.

Important point! Resin restoration can be carried out repeatedly, but gradually it becomes contaminated with impurities contained in the water and loses its ion-exchange capacity. Therefore, the ion exchanger cartridge must be replaced approximately once a year (depending on the intensity of use and water hardness).

There are many ways to make drinking water as safe as possible. Once upon a time, our grandparents did not hear about filtration systems. Today's ecology has complicated the situation with drinking water. Continuous cleaning heating devices from scale deposits makes you aware of water hardness and think about the quality of drinking water.

Removing hardness salts that are deposited on household appliances, possibly with the help of special softeners. Many filtration systems use ion exchange resin to soften water. Let's take a closer look at the types of resins, their operating principle and why they are used in the cleaning system.

Classification of ion exchange resins

In the fight against calcium and magnesium salts excellent option There will be reagent-free water softeners. Most of softening filters work using reagents. Water gets the right composition thanks to the filter mass and reagents. The latter can also restore filter media. The basis of the ion exchange filter is resin.

Ion exchange resin for water softening is used in many areas:

- cleaning;

- demineralization;

- silicon removal;

- selective filtering.

The resin is based on ion exchangers - insoluble polyelectrolytes. There are artificial, natural and synthetic resins.

Ionites have the form of a charged framework with ions opposite sign. When the framework ions come into contact with ions of a different sign, the ion exchangers change.

The direction of charge leads to the division of ions into ampholytes. Negative cation exchangers with positive aonites are added to them. Cations are attracted to cation exchangers, and anions to anoites.

The frame can have a different base: chemical, non-chemical, mineral-organic. It is a combination of organics and synthetic ion exchangers. If the frame is helium, then it contains macroporous or helium ion exchangers. They are active in the swollen state with an increase in volume up to 3 times. However, their resource is running out. When all cross-linking bridges are eliminated, the resin ceases to soften water.

There are resins with a uniform distribution of bridges - isoporous ion exchangers. With greater absorption, they increase greatly in volume.

The swelling of the helium base ion exchangers is caused by the opening of the granules like a flower bud. The helium structure does not have continuous walls and is not homogeneous. The disadvantage of helium resins is their inability to absorb large organic matter and ions. During filtration, “resin poisoning” can occur—clogging of pores.

Today, macroporous ion exchangers are the most used. Their advantages are a small change in volume, adsorb well, have long-lasting exchange reactions, high filtration rate, durable and rigid. Pores in microporous resins result from artificial process: Addition of fatty acids, alcohols and heptane.

If we compare existing species ionites, then you can see:

- macroporous ion exchangers are stronger than helium structures;

- helium anion exchangers perform worse than helium cation exchangers;

- polystyrene aonites are weaker than acrylic ones.

Working principle of ion exchange resin

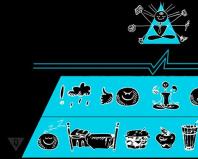

Filter circuit ( classic version direct flow technology)

IV - source water; OS - treated water; R - reagent

Softening resins began to be used only in the second half of the last century and quickly became obsolete. It was done in the 20th century maximum number discoveries in the field of water purification. The peak of popularity of ion exchange resins was in the 80-90s. Then they began to be replaced by membranes and reverse osmosis. Today, water softening resins are popular in purification systems, but do not occupy a leading position.

To better understand the principle of operation, ion exchange resin can be compared to caviar. An inexperienced person may confuse it with a beluga at first glance.

It was previously said that resin for water softening can consist of three types of ion exchangers: anion exchangers, cation exchangers and aonites. The most common aonites. The essence of the division is that each type can replace exclusively ion exchangers of the same name.

Anion exchangers may have a strong or weak base, as well as intermediate and mixed. Cation exchangers have weak or strong acidity. The strong base of anion exchangers allows exchange at any acid-base balance, weak - only up to 6. Strong acidity cation exchangers can be exchanged at any pH, and weakly acidic ones - up to 7.

Thus, the ion exchange resin softens the water, but almost does not purify it from other impurities. It can completely eliminate stiffness. It is possible to pass the water through the filter several times to make it softer. With each cleaning, the sodium concentration increases, great importance which is dangerous for the human body.

Ion exchangers can have a salt or mixed form. The salt base is made up of sodium and chloride compounds, and the mixed base is sodium chlorine or hydroxyl chloride.

Ion exchange resins are used in pharmacology, the food industry, at nuclear power plants for condensate purification, etc.

Sometimes tableted salt is additionally used to soften water. But regular table salt in tablets washes out the ion exchange resins from the filter. Over time, the resin will crack and lose its filtering abilities.

Salt tablets can restore the ion exchange resin. They sell it in large bags of 25 kg.

How to choose?

Traditional ion exchange resins: carboxyl resin, sulfonic cation resin

Today, in many stores on the shelves it is easy to find resin for ion exchange filter. If the brand and reputable manufacturer of the ion exchange resin is already known, then it can quickly be found on the Internet.

The main indicator of performance is humidity, not absorption. The resin contains chemically bound moisture. Removing it leads to the destruction of the ion exchange resin for water softening.

Next, you should pay attention to the ion capacity - working, volume, weight. Volume and weight are standard specifications, which are determined in laboratory conditions. They are always indicated in the product passport.

It is impossible to measure the working capacity. It depends on the shape and depth of the filter resin layer. The input parameters of the purified water are also important.

You should pay attention to the filtration speed, recovery level, particle size, etc.