Construction company sip. Advantages of purchasing a house made of sip panels on a turnkey basis

Construction

Construction of houses from SIP panels at a price of 4,800 rubles per sq.m.

Total special offers: 40

Pros of use

Prefabricated houses made from SIP panels are the most popular among prefabricated houses. In all countries, the construction of SIP houses has become fashionable, since high quality behind low price- this is the most profitable option.

One of the most important advantages that prefabricated houses made from SIP panels have is the speed of construction. In just a few weeks, owners will be able to celebrate their housewarming if they use this construction technology.

One of the most important advantages that prefabricated houses made from SIP panels have is the speed of construction. In just a few weeks, owners will be able to celebrate their housewarming if they use this construction technology.

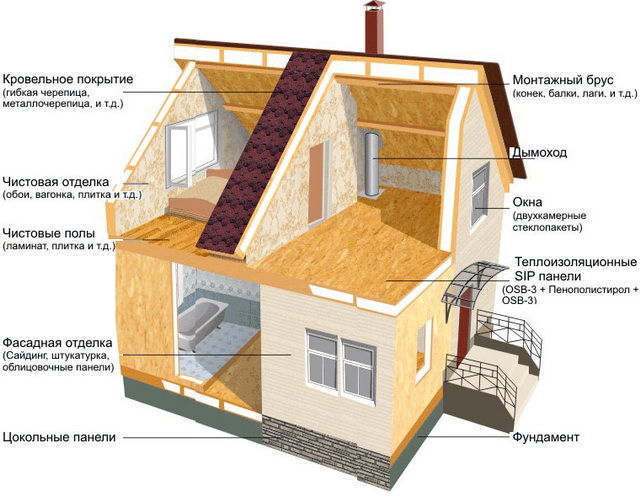

Prefabricated houses from turnkey SIP panels are built using the technology of connecting individual modules produced at the factory, which are assembled into a house body at the construction site. Held complete installation houses made of panels, together with the construction of the roof of the structure.

SIP panels are not just a popular trend today, this technology meets all the requirements and standards of housing construction. The demand for the construction of houses from sandwich panels is due to the low price, which is economically beneficial for those who do not want to live in a cramped apartment.

SIP panels are not just a popular trend today, this technology meets all the requirements and standards of housing construction. The demand for the construction of houses from sandwich panels is due to the low price, which is economically beneficial for those who do not want to live in a cramped apartment.

The construction principle is very simple

In the 3D video you can watch the stages of building a house:

In order to build a house using SIP technology, kits are provided to the construction site components future home, and directly on the territory allocated for the house, the assembly of all components begins.

Thanks to the properties endowed with these modules, it is possible to create luxurious houses from SIP panels that have a fairly attractive appearance, while the exploitation of housing is significantly high, meeting all the requirements of a residential building.

Thanks to the properties endowed with these modules, it is possible to create luxurious houses from SIP panels that have a fairly attractive appearance, while the exploitation of housing is significantly high, meeting all the requirements of a residential building.

Construction using SIP technology can be used for any purpose - you can build a beautiful country cottage from SIP panels, a summer cottage Vacation home, compact one-story houses or build a new village. Also frequent orders are the construction of individual structures, one-story warehouses, workshops of any size, garages, etc. All this is possible thanks to a completely simple design.

What is needed for construction

First of all, you need a project, which you can choose on our website in the section “projects of houses from SIP panels” or order an individual design according to your dimensions.

First of all, you need a project, which you can choose on our website in the section “projects of houses from SIP panels” or order an individual design according to your dimensions.

Next, according to the project, in our production we prepare a house kit with all the necessary building materials for building a house according to the project. On the house kits page, you can familiarize yourself with the kit options. The EcoEuroDom company provides the opportunity to order just a frame for self-construction of a house, as well as a frame and turnkey construction of a house from SIP panels, the prices of which also vary depending on the selected options.

If you want to build a house on your own, then when you order a set of materials, our specialists will prepare for you detailed instructions on assembly and will provide consultations on construction to avoid possible mistakes.

If you want to build a house on your own, then when you order a set of materials, our specialists will prepare for you detailed instructions on assembly and will provide consultations on construction to avoid possible mistakes.

You can find out more about self-assembly in the section - House kit "Assemble it yourself".

Material characteristics

The construction of houses from SIP panels has become in demand due to the quality and specific features of the material that is used as modular SIP panels. Such SIP panels have significant differences from other materials that are also used in the construction of houses.

The construction of houses from SIP panels has become in demand due to the quality and specific features of the material that is used as modular SIP panels. Such SIP panels have significant differences from other materials that are also used in the construction of houses.

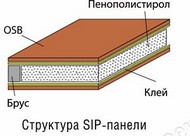

The basis of the design building element SIP panels lie on two wooden slabs or OSB boards, between which a dense layer of insulation - expanded polystyrene - is laid.

The dimensions of the completed element of a house made from sandwich panels depend entirely on the components, namely the type of slab and insulation. IN complete assembly the module does not exceed the dimensions of 1.25 × 2.8 m. Individually, the constituent elements have the following dimensions:

- OSB board - from 9 to 12 mm.

- expanded polystyrene - from 100 to 200 mm.

A panel-frame house using SIP technology is of high quality due to the properties that the SIP panel has:

A panel-frame house using SIP technology is of high quality due to the properties that the SIP panel has:

- savings on lifting equipment and construction equipment due to the fact that the SIP panel is lightweight and can be easily transported to the site of construction work;

- SIP panels are not influenced external factors thanks to a special coating that repels water. This feature of the slab makes it possible to build prefabricated houses from SIP panels at any time of the year and in any weather conditions.

- have an irreplaceable physical trait - they are malleable to processing. The required shape can be easily cut from the slab, while the slab will retain all its qualities of strength and reliability of the structure as a whole;

- Thanks to its structure, the stove retains heat in the room as much as possible. The SIP panel has low thermal conductivity, so we can safely talk about saving on energy resources when heating in winter;

- slabs are an environmentally friendly material. Such material can compete with natural wood.

Frame houses using SIP technology have maximum usable area, thanks to small sizes SIP panels. Thin walls occupy much less living space than walls made of blocks or bricks.

Characteristics of a house made of SIP panels

- Heat saving. Houses using SIP technology have high heat retention rates.

- Strength. The construction of houses from sandwich panels proves in practice that they can withstand destructive natural phenomena (earthquake, tornado). The construction of houses from SIP panels even provides the possibility of constructing high-rise buildings.

- Savings not only on building materials, but also on the finishing of internal and external surfaces. The evenness and clarity of structures makes it possible to avoid unnecessary plastering, leveling, etc.

- Saving on foundation. Houses using SIP technology require simple foundation due to the low weight of the structure.

- Speed. When building a house, sandwich panels allow you to quickly create the structure provided for by the project.

Why clients turn to EcoEuroDom:

- A house made of SIP panels, built by the EcoEuroDom company, will last longer than a house made of brick, laminated veneer lumber, or foam block. The prefabricated house is strong and durable, as proven by use in a wide variety of climates!

- In the production of sandwich panels we use only OSB-3 sheets produced by German company Glunz. Practice has shown that for all technical specifications, geometry and environmental friendliness, only OSB data are the best on the world market.

- Heating costs are 7-8 times less than standard heating brick house. A house from the EcoEuroDom company fully pays for itself within 10 years only by saving money on heating.

- The houses do not shrink, which allows you to install windows, doors and move into the house immediately after construction.

- At least 20 times faster than traditional methods. Installation of a house by EcoEuroDom, depending on the complexity of the project, is carried out within 2-4 weeks.

- The cost of a house from "EcoEuroDom" is 30-70% lower than when built from timber, foam-aerated concrete blocks or bricks. There is no need to use any heavy construction equipment.

- The technology for constructing low-rise buildings from SIP panels does not impose any restrictions on architectural and planning solutions, and allows the implementation of a wide variety of projects.

- If the family budget is limited, you can assemble the house yourself. In addition to assembly drawings, you will receive step by step instructions, in which the processes are described in detail down to the last detail. This option is especially relevant for those whose budget is limited and for customers from distant regions.

Alexey Shamborsky, 03/29/2016

The technology of building houses from SIP panels has been used for several decades in North America. Such construction is also common in Europe. The popularity of this technology is due to the reliability of the design, high speed construction, regardless of weather conditions, with good thermal insulation properties. The ease of assembly makes it possible to build a house from SIP panels with your own hands without the involvement of a large team and heavy equipment.

Features of this technology

You can be convinced that this type of construction is feasible by looking at the photo report below on the completed construction work. The information below shows how to build a house from SIP panels yourself.

For complete clarity, it should be noted that the concept of SIP panel came from in English- SIP (Structural Insulated Panel) translates as structural insulated panel (see photo).

Houses made from such sandwich panels cope with both lateral loads (hurricane winds) and the weight of snow on the roof.

The main stages of building a house from SIP panels

If construction is planned on land where there was nothing previously, the placement of a house on the site will be associated solely with the personal preferences of the owners, and with the placement standards regarding land boundaries. If there is a pipeline nearby or sewer drains are installed, care must be taken not to interfere with communications during the construction process.

Markings are made for the foundation.

![]()

Construction of the foundation

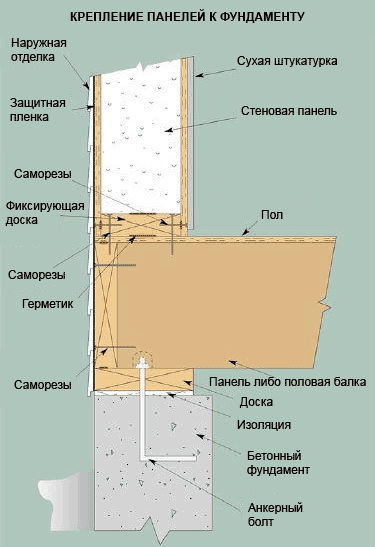

The light weight of a house made of sandwich panels allows you to minimize the cost of building a foundation. A massive structure is not needed here. Lightweight buildings made from SIP panels can be installed on following types foundations:

- tape;

- pile-screw;

- slab

Of course, you can equip the basement floor.

Here it was decided to build a house without a basement. First, with the help of heavy equipment, they equipped the site and made a small deepening under the foundation. When the recesses are made according to project documentation, arrange the formwork and fill it with concrete mortar.

Cinder blocks are installed on the strip foundation, which are reinforced and filled with concrete.

![]()

In this situation, 988 blocks were used. It turns out to be a rather high base of the house. This helps protect your home from moisture and insects. Instead of cinder blocks, you can simply use concrete to fill the base.

Arrangement of the lower level

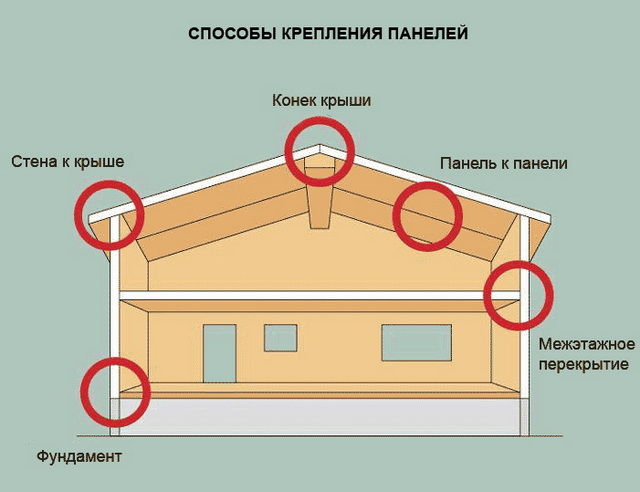

SIP panels are considered to be very durable. You can easily find a video of a truck driving over such a panel, and it does not deform at all. Therefore, the floor in the house is made from this material. Only first, waterproofing is laid on the foundation. The first panel is placed on it, aligned with the corner of the foundation. The joints between the panels are filled with foam. A connecting key is also installed there. The second panel is attached close to the first. The connecting dowels to which the panels themselves are screwed will add rigidity to the entire structure.

When laying panels, you need to check the level. If there are deviations, they must be eliminated. The end part of the laid panels is covered with strapping boards; foam is used to fasten them. As a result, the floor of the first floor will externally resemble a monolithic panel.

Laying communications

Pre-prepared technological holes are used for laying communications. This is both a water supply system and a sewerage system.

This work must be carried out before laying the finished floor.

Arrangement of internal partitions

Usually internal partitions installed simultaneously with the construction of load-bearing walls.

Houses made from SIP panels are especially popular today. Canadian technology allows the construction of durable buildings at minimal cost.

Let's talk about the features of SIP panels. This modern material consists of OSB boards, between which there is a layer of insulation. Typically, polystyrene foam is used as a layer for heat and sound insulation.

OSB boards of wood origin. They are designed directly for construction. For OSB, chips are suitable, the length of which is 15 cm maximum and the thickness is 0.7 mm. They are laid in three layers. During the production process, the surface is specially treated. This guarantees the material's resistance to water and fire. Protection against rotting is also guaranteed.

The slabs are as environmentally friendly as possible. Main material for production - wood. OSB is not afraid of humidity and temperature changes. The boards hold screws and nails perfectly. No pre-drilling is required.

The connecting element in the process OSB production The slabs become waterproof type resin. The chips are pressed under high pressure and at high temperature. Expanded polystyrene acts as insulation.

Production of SIP panels - indeed difficult process, which can only be performed by professionals.

Expanded polystyrene

Expanded polystyrene is a gas-filled material. It is made from polystyrene and derivatives. Styrene copolymers are also used.

Styrene granules are initially filled with gas. Then it dissolves in the mass of polymers. Next, the mass is heated using steam. As a result, the original granules increase significantly in volume. They completely occupy the mold and eventually sinter.

Expanded polystyrene has optimal properties thermal insulation. He is not afraid of moisture. Stable performance is guaranteed in regions with humid and cold climates.

Expanded polystyrene does not contain substances that feed microorganisms, so mold, bacteria, and fungus do not form.

SIP panels

For the manufacture of SIP panels, environmentally friendly material is used. At the same time, they fully meet safety requirements and regulations.

The material contains no harmful components. During operation, clean air is maintained in homes.

Today, almost all elements of the future building are manufactured at the factory. The house is just being assembled on the customer's premises. This work takes a maximum of two weeks.

Let's talk about production

The production of SIP panels is carried out in stages. First, OSB sheets are laid on the machine. Special guides allow you to position the material perfectly evenly.

Using a special station, the required amount of glue is applied to the sheets. For high-quality gluing, water is distributed. Then polystyrene foam is laid. Glue is placed on it again. The third layer becomes the second OSB board. An OSB sheet for the next panel is laid on top, since several boards can be pressed simultaneously using the machine.

When the polymerization of the adhesive is completed, the panels are moved to a special table and then to the finished product warehouse.

Basic SIPs are sawn according to drawings. A circular saw is used for this. Finally, a groove is formed on the panels using a machine.

If you are interested in the production of SIP panels, the Moscow region is an excellent region for this.

Ask a Question

Fill out an application on the website. Our manager will contact you to clarify details.