How to make a drilling machine with your own hands. How to assemble homemade tabletop drilling machines? Drilling machine based on asynchronous motor

Using a conventional hand drill, it is almost impossible to manually drill a strictly perpendicular hole in a thick block or perform a series of precise parallel drillings. Buying even an inexpensive drilling machine for this purpose is extremely wasteful if similar work is episodic in nature.

Exist special devices for factory-made electric drills, expanding their capabilities in this regard. Click on the small pictures on the right to view them in more detail.

Their use allows you to turn a drill into a kind of drilling machine. Of course, you can get one of these devices by choosing it for your tool, but you can make a drilling machine from a drill with your own hands. Let's consider several approaches to solving this problem.

Do-it-yourself drilling machine from a drill, drawings

Detailed drawings of such a device cannot be found even on the Internet. This is partly explained by the multiplicity of approaches and technical solutions, and partly by the simplicity and availability of methods for solving this problem. Let's analyze those that we managed to find.

This one is perhaps the most detailed and detailed. The main advantage of this arrangement is the absence of any gear pairs that ensure vertical movement of the drill along the stand, which is the basis of the device. The spring-loaded holder moves along the stand by the distance between it and the lower stop, minus the thickness of the compressed spring. To prevent its rotation in the horizontal plane, there is obviously a groove in the rack along which the screw 16 moves. The location of the tool in the holder is determined based on the parameters of a particular drill.

Even easier to implement on your own is a drawing of a wooden stand for a drill.

Not all sizes are shown on it, due to the fact that they are not of fundamental importance. And the lever feed system, as in the previous case, will ensure strictly parallel movement of the electric drill along the rack. Holding the tool in the upper position is achieved due to friction forces in the grooves and on the side cheeks of the holder and is regulated by the tightening force of the screws.

If you have a spare pair of screws, perhaps from an old vice, it can also be used for the tool feed system in a homemade electric drill stand.

For small drills, you can also use a regular threaded rod Ø 16-20 mm with a corresponding widened nut, which are sold in hardware stores.

Simple designs of homemade stands for a drilling machine

We have selected for you easy-to-make, but in our opinion interesting designs of stands for homemade drilling machines based on an electric drill.

Such wooden stand can function successfully without a lever, and the tool is raised and lowered either by the handle of the tool itself, or by the upper part of the box in which it is secured.

An interesting design is in which the system of 2 levers is replaced by 1 with a longitudinal groove along which the thrust screw moves.

A productive method is to combine materials for stands to turn an electric drill into a drilling machine. Thus, the main material for their manufacture is wood, but the most wearable components are made of metal, which radically extends the service life of the entire device.

An interesting design using industrially produced furniture runners as guides:

The high precision of their execution has virtually no backlash.

The process of creating a stand for an electric drill is greatly simplified if you have a photo enlarger of any model at your disposal. It is unlikely that it will ever be able to serve you for its intended purpose, but it will make an excellent drilling machine. After all, it already has in its design both guides and a gear rack for moving a rather heavy head along them, instead of which a holder for a drill should be hung.

No less productive is the option of converting old Volgov or Zhiguli rack jacks into a drilling machine rack. After all, you do not need their entire height for the normal operation of such a device, but only a small space of the screw.

To do this, you just need to slightly modify the lifting lever, in which to secure the drill, and the thrust pad.

And here is the video:

You can do it even simpler by rigidly securing the drill to the top of such a jack, and placing a work table on the lever. Do not lower the drill for drilling, but lift the workpiece itself, especially since the lower part of the screw in such jacks is the least worn.

And in general, the same principle can be applied to fairly large and powerful drills, securely fixed in any way on a powerful stand of the future machine. And you can make a small lifting table in the image and likeness of what is shown in the video:

Or use a small diamond-shaped car jack for the same purpose, providing it with a reliable base and replacing the upper stop with a working platform with a vise or a prism.

Moreover, both the first and second can be made removable, and in long time intervals between drilling work the jack itself can be used for its intended purpose.

More powerful drill press designs

And yet, when we talk about a drilling machine, we mean something more thorough than described in previous section, and the material for such devices should be metal, even if we are talking about very small machines for low-power power tools, like this one:

And even such a primitive design significantly expands the capabilities of a hand drill. But how to make an almost full-fledged drilling machine with your own hands, without using complex technical solutions for this? Of the simplest, the most reliable design seems to us to be this:

Its biggest drawback is the ability to freely rotate the holder, and with it the drill, around the stand, but if you use square or rectangular pipes instead of round ones, this drawback will be eliminated. The main thing: very carefully select the size of the gaps between the stand and the movable bushing of the drill holder frame.

A slightly different, but no more complex technical solution for feeding the tool to the part being drilled was implemented by a home craftsman from the video:

In conclusion, about choosing a drill

If you are just planning to select a specific drill model with the possibility of using it in conjunction with the device, the designs of which we described above, then:

1. Give preference to a tool with a power of at least 1 kW.

2. Choose a model with a removable handle, secured with a circular clip around the girth. They have a convenient wide cylindrical part on the body for mounting in a holder.

3. Choose a tool that has multiple speeds or smooth speed control.

4. The button on your drill must have a lock in the on position.

5. It is better to connect the drill on the stand to the network through a socket or extension cord that has a power button, and firmly fix it on the frame in a place convenient for emergency shutdown.

Dear readers, if you have any questions, please ask them using the form below. We will be glad to communicate with you;)

A home drilling machine (simply a drill) is equipment that anyone who has ever made anything feels an urgent need for. Craftsmen sometimes make drilling machines with 2-speed gears, workpiece tables with more than 3 degrees of freedom, and even two-axis CNC drilling and milling machines, see fig. below. But in this publication we will look at making a drilling machine with our own hands - one that simply drills and mills - but accurately, cleanly, and confidently maintains its accuracy for a long time subject to occasional short-term overload: stable processing accuracy is the main requirement for metal-cutting equipment. Which in amateur designs is carried out, unfortunately, most often only due to a random coincidence of circumstances.

Metal or wood?

Wooden drilling “machine” monster

Beginners always think that woodworking is easy and simple. The spoiled workpiece will be suitable for small crafts or fuel. Perhaps that's why in Lately There is a real craze: homemade machines with critical wooden parts. As a result, monsters are sometimes born that would probably surprise even Archimedes, see fig. on right. However, remember: the best achievable accuracy on wood is +/- 0.5 mm. In metal cutting, the default maximum permissible error is 0.375 mm (in England and the USA 0.397 mm = 1/64 inch). At this point, the question of using wood as the main structural material of the machine is closed without discussing the fact that, they say, wood is also orders of magnitude lighter than metal, deformed, worn out and damaged. Well, for lovers of deep inner self-satisfaction in products - free will for their money and work.

Drill device

Fantasy is an indispensable condition for any creative success, but in mechanical engineering it is useless without accurate calculations and comparison with solutions proven by experience. The history of machine tool construction goes back thousands of years - foot-operated bow lathes and drilling machines were used already at the end of the Stone Age. On the topic of this article, a proven sample is an industrial-style desktop vertical drilling machine. We will refer to it when choosing and deciding how best to make a drilling machine with our own hands: there are only a few examples of drilling machines in use that are over 100 years old, and they still maintain accuracy.

The structure of a desktop vertical drilling machine is shown in the figure:

Its main modules are a bed, a column, a console and a table for a part. The components of the main nodes are slightly highlighted in color, and their components are brighter in color. The simplest table(not counting the wooden block) - a vice. The rotary-sliding table allows, in addition to drilling, to perform some milling operations. The bed is usually tightly attached to a workbench or other reliable support.

Screw clamp – clamp of the mini-drilling machine console

In operation, the console is installed in the required position in accordance with the size and configuration of the workpiece using the lifting and rotating mechanism of the slider, and is fixed. The spindle is fed into the working stroke by a separate feed mechanism. In amateur and industrial designs for home use, the lifting and turning mechanism is most often the operator’s hand, and the lock is a screw clamp of the slide, see fig. on right; According to TB, both are acceptable. But what must certainly be in the design of a drilling machine according to the requirements of the same safety regulations is a bumper device or just a bumper: if you throw the feed handle, the spindle or carriage along with it should automatically bounce up until it stops. In home drills, the chipper is most often a spring installed in a suitable place, see below.

Note: industrial production, the sale and use at enterprises and workshops of individual entrepreneurs of drilling machines without a fender device is prohibited by PTB.

Make or buy?

An electric drill is a ready-made drive, gear, spindle and chuck in a monoblock. Place it on the carriage of the machine and you can drill. In terms of accuracy, the solution, generally speaking, is not optimal (see below), but in many cases it is acceptable, but eliminates the need to order expensive turned parts of increased accuracy, see below. In view of this, frames for installing drills are now sold only on the street from trays; prices are affordable. When choosing one to make a drilling machine from a drill, be guided primarily by the operating mode of the equipment; The price also depends on it:

- Occasional drilling/milling for yourself with the accuracy of what you get - cast plastic bed or stamped steel. The feed mechanism is lever with a cranked lever (see below). Carriage sliding bearings (see below) are steel on steel or with nylon liners. Prices are $20-$30.

- Regular drilling for yourself or to order with ordinary machine-building precision. The materials processed are up to the hardness and toughness of ordinary structural steel. Everything is the same, but the sliding bearings are steel on steel (worse) or with bronze bushings, and the frame is cast iron or (more expensive) composite, also vibration-absorbing. Prices: $30-$40.

- Regular drilling and milling of any materials that can be tooled with periodic overloads of the tool and/or with increased accuracy - plain bearings are only bronze on steel, cast iron frame. The feed mechanism is rack and pinion (see below); vibration-absorbing console. Prices – $60-$180.

Note: As a rule, drill beds are optionally offered with a rotary-sliding table for the part, allowing the production individual species milling. Price within $20.

Choosing a bed

The stand for the drill (which sellers for some reason stubbornly call stands) should not be selected according to the manufacturer (“China” is not “China”); Now the market is full of “German China”, not to mention products from post-Soviet states. The design needs to be checked.

First, samples with plastic non-nylon liners for sliding bearings are definitely rejected: runout and drill drift of more than 0.5 mm will appear already on the 10th – 20th “hole” and will further increase. The second is console play. We take it by the far end, swing it up and down and to the sides while holding the latch. There should be no noticeable “chatter” (the tactile sense of an untrained person feels a beat of 0.4-0.5 mm).

Next is an inspection of the structure, see Fig. below. For regular drilling, the one shown in pos. 1. The ideal option is at pos. 2: collet clamp of the drill, shifting the column to the side reduces the vibration of the console by an order of magnitude, and by turning it sideways by 45 degrees, you can mill the part by hand with the precision “as best you can” on a standard fixed table, removing a couple of table fasteners, because in this case, its manual displacement relative to the horizontal working axis of the console will be linear.

And here is a sample for pos. 3 do not take under any circumstances. Firstly, the collar of its column is low and its fastening is unreliable. Secondly, longitudinal grooves under the table facilitate manual milling “as it happens,” but, unlike diagonal ones, they do not dampen vibrations of the bed. Moreover, they will concentrate where shown by the arrows (the tide under the column is made too narrow) and from there they will go straight into the column and table.

Which is cheaper?

Let’s say the price for the machine you like doesn’t suit you. Or a drill, if it’s a “crowbar” one, with an impact mechanism, that was used in work on building structures and the beating of the chuck is visible to the eye. Then the first thing we do is find out if there is a craftsman within reach who owns a lathe with high precision (no rougher than 0.02 mm). Which, by the way, is not a fact - a high-precision machine is very expensive and never pays off with the flow of regular orders. But let's say he was found. We take the drawing in Fig. on the right, we go to him and ask if he can turn it out of steel no worse than 30KhGSA, and how much he will charge for the work. “This” is the drawings of the tabletop drill spindle. The rest of its details can be turned on on a regular machine, or found in ruins at an iron bazaar or in your trash. Most likely, it will turn out that it is cheaper to buy a bed + table, and if you estimate the costs for the rest, then perhaps a drill of increased accuracy will emerge. There are some of these on sale; they can be recognized by the absence of a striking mechanism and a collar specifically for installation in the frame: a turned steel cuff is put on it.

If you do anyway

However, there may be cases when a homemade drilling machine will either cost less or be completely free, or the most best drill it will not replace it on the bed. The fact is that, in addition to bending and vibration loads, torsional loads from the working tool (tool - drills, cutters) are also transmitted to the column. This is due to the difference in the lever arms from the axis of the column to the nearest and far edges of the tool; the torsional loads from a cutter gnawing the material with one edge are an order of magnitude greater than from a drill. Therefore, it is unrealistic to achieve a machining accuracy of more than 0.1 mm with a drill on a bed (see below for why), but let’s say a hole of 2.7 is needed for an M3 thread; under M2.5 – 2.2, and the processing error in this case turns out to be unacceptable. In general, making a drill with your own hands makes sense, despite the costs, if:

- You are a radio amateur and work with components with pin pitches of 2.5 and 1.25 mm (“millipedes” with a pitch of 0.625 mm are mounted only on a plane). Then you need a drilling machine for printed circuit boards with an accuracy of no worse than 0.05 mm;

- You do other fine wood and metal work. For example, it is impossible to make a beautiful, elegant box or a reliable hiding place in the house using only hand drilling;

- You drill/mill from time to time for yourself and the accuracy will suit you, but the stash is full of all sorts of junk metal.

Note: in the latter case, you are lucky, suddenly there is an old children's bicycle lying around somewhere. Its frame tubes are of excellent steel, and the wheel hub is almost a finished spindle; The only option available to order is an adapter with a Morse taper for a tool chuck. Working thoughtfully and carefully, an old bicycle can be turned into a drill press with an accuracy of approx. 0.1 mm, or actually a free drill stand, see for example. video:

Video: DIY drill stand

Layout

But let’s say we need higher accuracy, and we need to mill the grooves without losing it. In this case, the layout of the machine becomes of paramount importance.

The best option is to locate the spindle and drive on opposite sides of the column, pos. 1 in Fig. The heavy motor in this scheme acts as a counterweight to earthquake-resistant buildings: it reflects vibration and torsional loads from the spindle in antiphase. In the region, the columns partially cancel each other out. The damping is maximum if the center of gravity of the carriage is exactly along the axis of the console, and the higher, the thinner the drill and the less pressure on it. That is, the accuracy of the machine in delicate work increases, and at the same time, it can withstand quite significant overloads without losing it.

Note 4: it is possible to make a drill for precise work with a direct drive to the spindle and the location of it and the drive on one side of the carriage if there is a ready-made vibration-damping frame, for example. from an old microscope (under 2), etc. optical devices.

In mini machines for printed circuit boards and jewelry work, an unpleasant effect is observed: in order to obtain an accuracy above 0.05 mm, the column has to be made disproportionately thick, pos. 3. This is due to the fact that its ability to absorb vibrations and torsional loads is determined by the cross-sectional area, which decreases squarely as the size of the part decreases. For circuit boards for components with a pin pitch of 2.5 mm, as well as minor metalwork and carpentry work, an accuracy of 0.05 m is sufficient. In this case, the main influence on its deterioration is exerted by column bending loads. To fend them off, it is enough to use a double column made of a 10-14 mm bar made of ordinary structural steel, pos. 4. If the usual accuracy of 0.375 mm is sufficient, then by doubling the column, a drilling machine for occasional work can be made even from a drill and propylene water pipes, pos. 5. Its service life before loss of accuracy is small, but the material is cheap and does not require custom processing.

Innings

The design of the spindle feed mechanism (carriage in a drill machine) also plays an important role in drilling accuracy: jerks and/or uneven feed force at least increase drill runout. When drilling with a thin carbide drill, in this case, it is very likely that it will slip, break, and, as a result, irreparable damage to the labor-intensive workpiece.

In machines and stands for high-precision drills, a rack-and-pinion feed mechanism is used (on the left in the figure), ensuring its complete uniformity and, which is especially important for manual feed, exactly proportional impact of the tool stop in the hand. This requires a rack and a gear-tribe with a well-defined tooth profile - involute. Otherwise, the feed will be jerky even with absolutely smooth pressure on the handle. It is unrealistic to make a rack-and-pinion pair with identical involute teeth “on the knee”; Finding a suitable ready-made pair is unlikely, so rack-and-pinion feed mechanisms are extremely rare in homemade drills.

More often they make a simple single-lever feed mechanism, in the center in the figure, but this is far from optimal. At the beginning and at the end of the working stroke, when the smoothness of the feed and the accuracy of drilling are especially important, it does not transmit enough emphasis to the hand, and in the middle of the stroke it is excessive, which increases the likelihood of the tool getting stuck in viscous material. The feed mechanism with a cranked breaking lever on the right is free from these shortcomings; in addition, it additionally dampens console vibrations. The knee shoulder ratio is taken to be approx. 1:1.

Serving table

Drilling thin, fragile/ductile parts is more accurate, and the likelihood of the drill leaving and breaking is less if the spindle is fixed and the table with the part is fed upward towards it, therefore, in many drills for fine work, the table is equipped with a separate feed mechanism. Due to the inertia of thinking, it is often also made rack and pinion, see for example. Further. But, taking into account that the mass of the table in this case is much greater than that of the part, a table with a lever feed turns out to be no worse, but completely accessible for manufacturing at home. Its device is shown in the figure:

There is only one nuance: so that the clip does not move during assembly, it is tightly inserted into through hole base and welded from below (from the bottom). You need to cook with an OMA-2 electrode or thinner with a direct current of 55-60 A using short, diametrically opposed clamps (“poke”). Table dimensions for printed circuit boards and jewelry work are 60-150 mm in diameter; thickness 6-12 mm. Table shank diameter 12-20 mm; length per feed stroke +(20-30) mm. It is advisable to machine the tube for the shank (wall thickness from 1.5 mm) or drill it and pass it with a reamer so that the shank moves smoothly in it without noticeable play. The short lever arm is made to be approx. equal to the diameter of the table; long - whatever you want.

Console

Let's look again at Fig. with factory frames. The designs of their consoles with half-frame carriages are similar; they are quite rational, but are designed for automated and robotic production: precision casting and then finishing on site on a CNC unit with laser measurement.

A diagram of an analogue console with an amateur-made half-frame is shown on the left in the figure:

The first thing that attracts attention is that you need to cut out 5 parts from a thick steel sheet, trimmed (processed end mill) for evenness and parallelism of the sides. Second, the end cuts of inserts filled with dark gray must also be smooth, clean, and parallel. Those. and here you can’t do without a milling machine. Finally out production conditions it is unrealistic to perform a sliding interface between the slider and the guide carriage (shown by the arrow) with a backlash of less than 0.1 mm. Let's estimate the ratio of the lever arms - the transverse runout of the drill turns out to be more than 0.5 mm.

The design of the console of a drilling machine, which is not technologically advanced in mass production, but is adapted for production using artisanal methods, is shown on the right in Fig. (the feed mechanism and drive with bracket are not shown). Moreover, in it, the runout of the drill on inhomogeneities of the material causes the carriage on the column and the guide to skew in opposite directions, and the lateral movement of the tool does not exceed the amount of play in the sliding liners. Only one part is cut out of a thick plate - slider 4. Its precise processing is necessary only in the area of clamping the column and installing the guide, and 3 bronze bushings-liners will be precisely adjusted in place by any turner of average qualification, if you give him a column and a carriage guide (they can be machined with normal precision).

To prevent the entire assembly from welding, you need to cook it as before. case: electrode OMA-2 or thinner, direct current up to 60 A. The seams are also welded alternately with tacks: a “poke” on one, the same on the same distant one, located symmetrically. Then tack the seam closest to the first, the same on the diametrically opposite one, etc., etc., until all the seams are welded.

Note: The accuracy of a machine with the described console will be higher if it is assembled not by welding, but by screws and gluing with high-strength metal glue ( cold welding). First, everything is assembled without glue, the clips are checked for parallelism and the fasteners are tightened. Then the screws are turned out one by one, glue drips into the socket and screwed back tightly. It’s a tedious task, but in this way it’s possible to get a homemade drill with a drill runout of less than 0.02 mm. Unless, of course, the spindle and chuck are centered just as well.

Errors in design

All efforts to make a drilling machine with your own hands will go down the drain if fundamental errors were made during its design. The most common of them are shown in the figure:

Typical mistakes when making a drilling machine

Pos. 1 – is this a console or what? This frame will not withstand the normal load from the tool stop for long. There is no need to talk about accuracy. Pos. 2, in addition: it is impossible to make the column of the drilling machine tubular. The pipe can withstand bending loads, but is powerless against torsional loads, and only increases vibrations.

Pos. 3 – the temptation is great to make a drill from an old photographic enlarger, especially since it is made with at least initial, but optical precision. But! The magnifier rod holder is not designed to support the tool. As a result, when drilling hardboard, the drill drift at a feed rate of 20 mm reaches 1.5 mm (!). And the bracket is made of silumin: this material does not absorb vibration, gets tired quickly, and the bracket breaks in less than the 200th hole, even when drilling printed circuit boards.

Pos. 4 – doubling the column in the transverse direction does not give anything. The resistance of the machine to loads will be no higher than on a single pin of the same diameter. Pos. 5, in addition: a rebound spring that is asymmetrical relative to the axis of the column does not dampen vibrations and torsional loads, but enhances them. Since this is the case, it was necessary to install 2 identical springs on both racks. It would be better to make a column, as shown here:

Video: do-it-yourself drilling machine from a drill

Pos. 6 – installation of the drive and spindle on one side of the column, and even asymmetrical, does not reduce, but increases vibrations, because they are transmitted to the column in phase, see above. Pos. 7 – where is the bump stop? Yes, it cannot be here, since the feed drive is screw. Using a screw, you can accurately adjust the slider (which is not here at all), which is generally not necessary on a home machine, but under no circumstances should you feed the carriage! This structure will almost throw fragments of drills and shavings, and the operator’s eyes will be in close proximity to the danger zone.

Analysis of structures

Let's look at examples of successful technical solutions, as well as less significant design flaws, using the examples of several homemade drilling machines.

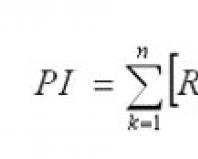

For a radio amateur, modeller, miniaturist and/or jeweler, a simple mini-drilling machine with direct drive may be of interest (the drawings are given in the figure on the right). The design feature is that the drive motor is rigidly attached to the slide, and the feed is only from below the table. The massive electric motor itself serves as a vibration damper and torsional load absorber, exactly like an anti-seismic load on high-rise buildings. Thanks to this, all parts, except for the Morse taper with an adapter on the motor shaft, can be performed with ordinary precision: the drilling accuracy is determined by the runout of the motor shaft + the runout of the cone with the adapter + the runout of the drill itself. A table with a rack and pinion feed mechanism can be easily changed to a lever one. It is better to use a commutator engine direct current: for asynchronous motors with capacitor starting due to the unevenness of the rotating magnetic field and the rotor slips and the shaft rotates less evenly. In addition, the rotation speed of a commutator motor is well regulated by at least a simple rheostat, but to adjust the speed of an asynchronous motor, you need to change the frequency of the supply current. The same for synchronous with a magnetic rotor. The maximum rotation speed of the motor shaft is 800-1500 rpm. Power on the shaft for drilling holes up to 3 mm – 20-30 W; for holes up to 6 mm – 60-80 W.

Note: This machine is not suitable for milling, because The motor shaft bearings are not designed for lateral loads and the machine will quickly lose accuracy in this mode.

Here in Fig. Given are the drawings of a fully functional mini-drilling machine for the same purpose, also with direct drive:

It is equipped with a separate spindle, which allows, firstly, to insert a drill of a maximum diameter of 6 mm into chuck No. 1a; For 8-10 mm drills the engine is rather weak. Secondly, perform milling with dental burs. Apparently, the author of the design often uses this particular operation, based on which the motor rotation speed was chosen. Without reducing it, you need to drill on this machine with carbide drills, and to use conventional ones, add a speed controller to the design; in this case, a motor of at least 60 W is needed. The glaring drawback of this machine - a simple lever feed drive - can be easily eliminated: the feed lever is replaced with a cranked one without modifying the remaining parts. To increase the accuracy of processing, it is also advisable to install a second rebound spring (item 14 in Fig. and 9 in the specification; there is still confusion there) symmetrically to the first, at the other end of the spindle driver. A more serious design flaw is that the rebound springs do not participate in damping vibrations and torsional vibrations. At rotation speeds above 5000 rpm, their influence on accuracy is practically not affected, but already at 1500 rpm, the runout of the drill during the working stroke increases by approx. doubled.

Drawings of a mini-drilling machine, intended to be structurally complete, but with annoying errors, are shown in Fig; The design of the carriage is similar to the console in the previous one. designs.

Thanks to the installation of a strong rebound spring in the proper place, it was possible to rigidly fix the spindle in the carriage, which at first glance reduced the number of parts requiring increased manufacturing precision. But only when feeding from below with a table, and even then, fixing the slider 5 and carriage 4 with pairs of screws 17 and 16 respectively. unreliable and damages the column; it would be better to use screw terminals. And when the released carriage is fed with a lever, only its joints prevent the carriage from turning. A play of 0.02 mm in any of the lever hinges, taking into account its relationship with the length of the knee arms, will result in lateral movement of the drill by 2 mm or more, which can only be countered by hand. In this machine, the most appropriate thing would be a console with an additional carriage guide, described above; in this case, it would be quite possible to achieve tool runout due to backlashes in the mating parts of the machine itself of no more than 0.02-0.03 mm.

In this fig. – drawings of a frame for a drilling machine from a drill with a half-frame carriage, “almost like the real thing.”

Everything about it is good, and some things are even better than the “brand”: plates 5, which prevent lateral movement of the carriage, perfectly “catch” and suppress tool vibrations in their very bud. There is only one question: how to do all this if in the garage (shed) there is a machine park worthy of a small machine-building plant, waiting for the owner’s hand? It’s easier to make a drilling machine from a drill as shown in the video:

Video: homemade drill stand

I can’t help but remember an old Soviet joke:

“Dear Comrade Leonid Ilyich honored with his visit a certain industrial enterprise. They are walking through the workshop, suddenly the Secretary General stops his retinue with a wave of his hand, and one approaches the worker at the machine:

- Comrade turner...

- Yes, Petrovich I...

- Fine. Comrade turner Petrovich, tell me frankly - do you drink vodka?

- Why not! Let's use it!

– And if a bottle costs 10 rubles, will you still drink it?

- Will.

- What about 25?

- Will.

- How about 50?

- Will.

- What about 100?

- I will anyway.

- Petrovich, ... but where can I get you so much money for your salary?!

“Gee... what does the money have to do with it... this little thing (shows) how it cost half a liter, so it will cost.”

Some are happy, some are sad, but those Petrovichs, general secretaries and industrial relations no longer exist. And they won’t – they turned out to be completely ineffective.

About steering drills

A fairly popular request on this topic is also “drilling machine from steering rack passenger car" It seems to be a ready-made converter of rotational motion into linear motion, and even with a geoidal transfer characteristic: in order to “peck” a little with a drill, you don’t need to “catch microns” with your hand. You just need to adapt the steering wheel to the rack, make a drill holder (see the figure on the right), and you're done, see the video.

A self-made drilling machine allows you to drill holes in different materials at a sufficient quality level at home.

1 Homemade drilling machine - who needs it and why?

Drilling in the extensive list of various plumbing operations is considered among specialists to be the most accessible and truly simple procedure. It is usually performed on special drilling units, which can have different functionality and some design features. The modern machine tool industry produces many types of drilling machines, ranging from very simple ones (for example) to CNC units that have several spindles.

It is clear that home craftsman in most cases, such machines are simply not needed, since they are intended to perform serial operations. And in everyday life it is usually necessary to carry out some single procedure.

It is for this reason that many home craftsmen decide to make a basic drilling machine with their own hands, using those parts and available materials that are available in any private garage.

As a rule, radio amateurs, as well as people who themselves perform simple household tasks, “light up” with the idea of making a homemade mini-installation for drilling. renovation work. In some cases, a simple electric drill is sufficient for this. But, if we are talking about more serious procedures, the drill, of course, is not able to guarantee normal quality and accuracy of drilling. That’s when it makes sense to start making your own mini-machine, on which you can install different ones.

2 How to make a drilling machine from a drill?

In home workshops, such drilling equipment is most often found due to its simplicity. self-made. You do not need high-strength materials or any special devices. The mini hole drilling machine includes just four key components:

- a bed that serves as the base of the machine;

- rotation mechanism (in our case, its role is played by an electric drill);

- feeder;

- vertical stand.

The stand is usually made from ordinary chipboard or boards, since the small weight of the drill does not require the use of more durable materials. But it is better to make the bed as massive as possible. This will ensure the absence of vibrations during the drilling process, and therefore more comfortable work.

Craftsmen advise using a relatively thick (from 2 centimeters) furniture board for the base of the unit. The ideal option is to use an old photographic enlarger for the manufacture of the frame and stand. It will only need to be slightly modified to obtain a truly reliable mini-machine design for home use.

The quality and accuracy of drilling on a homemade unit depends on the correct connection of the frame and the vertical stand. Therefore, this part of the work must be approached as responsibly as possible. It is recommended to cut two guides from steel strips, which are then connected to the stand with screws. The block with the drill will move along the indicated guides.

The block itself must be made so that it holds securely electric drill. This is easy to achieve using small steel clamps. It is also advisable to place a small rubber spacer between the block and the drill. It will significantly reduce vibration and make the installation process more comfortable.

The feed mechanism of a drilling machine from a drill is a simple lever that will move the block with the tool in the vertical direction. It is advisable to equip this mechanism with a spring of relatively high elasticity and power. One end of the spring should rest against a stationary wooden beam mounted on the stand, the other - against the block.

If you want to achieve maximum convenience in working with a homemade machine and do not plan to periodically remove the electric drill, it is recommended that you simply disassemble its switch and mount a separate button on the frame, with which you will start and turn off your drilling unit. As you can see, everything is quite simple. Any more or less handy man can make himself a small and convenient machine from a drill.

3 DIY drilling machine based on an asynchronous motor

Any owner in the garage, basement or somewhere on the balcony of the apartment stores many electric motors from electrical units that have served their useful life. From these, it is quite possible to choose a motor that will become the propulsion device for a mini-drilling machine. Ideal option in this case, an asynchronous type motor mounted on drum washing units is recognized.

Work on creating a home drilling machine using an old electric motor is much more difficult than using a drill. But they can also be accomplished, armed with a certain amount of patience and perseverance. It is important to realize here that the motor from the washing machine has more serious weight. And the power of such a “motor” is much higher than that of an electric drill. This means that you will have to take care of preparing a “mighty” stand and base for the machine being created.

Experts say that reducing the vibration level of a unit based on asynchronous motor possible by installing it on a powerful base, as well as by placing it closer to vertical rack. But it is necessary to remember that the close location of the rack and the motor can complicate the design homemade machine, which is caused by the need to install belt pulleys.

To make a drilling rig using an electric motor from a washing machine, among other things, you will need the following parts:

- gear;

- bearings in the amount of two pieces;

- hexagon;

- two tubes of small thickness (one of them must have an internal thread);

- clamping ring (preferably made of durable material, such as tool steel).

A hexagon is required to make the moving part of the machine transmission device. A pulley will be put on it. You also need to attach to the hexagon metal tube with bearing and steel ring. It is important to achieve a very tight connection of these components with each other, since otherwise they will completely collapse during vibration (not immediately, but quite quickly).

The adjustment complex of the unit is made of a gear and a tube on which cuts need to be made. They contain gear teeth. The specified tube is made of such a height that the drill chuck rises by a given amount. An axle with a hexagon is then pressed into the same tube.

From the described diagram it is clear that it is quite difficult to manufacture a machine with an asynchronous motor. Therefore, we can advise doing it by analogy with the previous process, when an electric drill was used. But be prepared for the fact that the resulting machine, unfortunately, will not be characterized by particularly accurate drilling.

When performing carpentry and plumbing work, an appropriate tool is usually used, designed to perform specific tasks. However, there are situations when it is much more convenient and easier to use special machines. They allow you to optimize the process and save time during the same type of work. Therefore, questions about how to make a drilling machine from a drill very often arise among modern craftsmen.

Necessity or luxury

First of all, it is worth saying that using such a device is very convenient when making holes in small horizontal planes. It almost completely eliminates the backlash that inevitably occurs during manual work. Even a small drill significantly increases the accuracy of the hole made, minimally reducing the error. Also, such equipment greatly saves time and effort if frequent use or monotonous work is required.

Almost all enterprises where plumbing work is performed are equipped with such units. The fact is that studies conducted in the field of occupational safety have shown an increase in productivity and quality when using them. Some of them even purchase a magnetic drilling machine to optimize production on large surfaces without the use of expensive equipment.

Why drill?

Currently, there are a lot of designs for creating such equipment at home. However, most experts recommend making a drilling machine from a drill. This is due to the fact that this tool already completely contains all the necessary components and assemblies, and they do not have to be purchased separately. In this case, the fixation on the structure is carried out so that the drill can be easily removed for independent work. As a result, we do not lose a tool that we can use ourselves.

Materials

In order to create a drilling machine from, you need to purchase the tool itself. It is selected in accordance with the parameters that the finished device will have to have. At the same time, experts advise paying attention to products that have their own slight play. Otherwise, the advisability of using it for work is called into question. You may also need:

- Guides. They use systems used in furniture production, or metal strips.

- Bed. Most often it is made from a metal plate or wooden box, on which magnets or ballast are attached for weighting.

- Fasteners When making a drilling machine from a drill with your own hands, you immediately select couplings or clamps suitable for fixing a specific tool.

- Wood or metal structures - depending on what material is to be processed.

- The spring required to implement the reverse motion.

- If a drilling machine is created, then the magnets themselves will be needed.

Tool

In this case, the selection of the tool used depends on the material for creating the frame. However, it is immediately worth noting that a corner for measuring the connection of elements at 90 degrees will be necessary in any case. Even a mini-drilling machine requires great precision during its manufacture, since this will subsequently affect the quality of the holes produced.

Drawing

First of all, you need to decide on the design of the final product and the material for its manufacture. However, there is no need to come up with too complex technical solutions or expensive units. Standard drawing The drilling machine from the drill is quite simple. It involves creating a strong and stable frame on which a vertical tripod with a movable carriage is mounted. Taking this into account, special attention should be paid to the implementation of moving the drill in the vertical plane, although the use of ready-made guides greatly simplifies this process. If you use the stand of a microscope, photographic enlarger or press as a frame, then the drawing will be based on their base, and the entire manufacturing process is greatly simplified.

Stand and tripod

Even a mini drill press needs a stable base. It should not only support the entire structure, but can be equipped various elements for fixing tools or other devices. When thinking about the design of a drilling machine, it is worth listening to the advice of experts. Many craftsmen recommend creating these devices from wood. Therefore, for the bed they use wooden frame in the form of a small box. There are seats on it for installing a vice or other structures. If the product is planned to be used on large surfaces, then the frame is made of a solid plate with a hole for a drill. This way you can implement the principle of drilling through.

Almost any drilling machine device involves installing a vertical tripod at an angle of 90 degrees to the bed. Therefore, it is very important to use an accurate one in your work. You also need to securely fix the tripod using additional mounts in the form of corners.

If the work involves working at a certain angle, then you can make certain devices in advance that will be attached to the frame. Most often in such cases, ready-made ball vices with adjustable angle tilt

Creating a Motion Mechanism

When making a homemade drilling machine from a drill, special attention must be paid to this stage. The fact is that the vertical stroke should be soft, without distortions, play or displacement. Taking this into account, professional craftsmen recommend using ready-made guides that can be taken from other devices. You can also use systems made to pull out drawers in cabinet furniture. They are quite reliable and can withstand heavy loads.

The guides are installed directly on the tripod or special strips attached to it. In this work, it is very important to use a measuring tool, since these elements must also be positioned at an angle of 90 degrees with respect to the frame and parallel to each other. Even small distortions or displacements should not be allowed.

The second part of the guides is fixed to a special carriage, where the drill itself will be installed. It is made of wood and adjusted to the dimensions of the original instrument. A small handle is also attached to the carriage, with which the operator will control the moving process.

To implement the return movement and facilitate control of the movement of the carriage, a spring is installed on the machine. One end of it is fixed at the top of the tripod, and the other is mounted on a movable mechanism. In this case, they immediately check the level of its tension, which, if necessary, can be changed by cutting the turns or stretching them. However, this adjustment is best done under load, which means it is performed only after fixing the drill on the carriage. Some craftsmen recommend making the spring removable so that it can be removed after work. This way it will not stretch and weaken.

Fixing the drill

Typically, instructions on how to make a drill press from a drill recommend creating special fastening systems that end up being very difficult to work with. However, if the tool is selected correctly, it can be fixed using ordinary plumbing clamps used to create connections between hoses and pipes. In this case, you will need to make certain changes to the shape of the carriage or even slightly adjust the drill body.

It is very important that the tool is clamped tightly and moves in the clamp. Therefore, even at the manufacturing stage of the carriage, they practically do not leave him free space, limiting structurally on all sides. In fact, the carriage itself is a kind of bed for the drill, in which it will sit very tightly. Additional elements are needed only for reliable fixation. This approach will greatly simplify the design and allow you to quickly remove the tool if necessary.

Conclusion

Taking into account the material presented above, we can conclude that a drilling machine from a drill can be made independently and without large financial costs. In this case, the final product will be maximally adapted to the performance of specific technical tasks and will be able to satisfy the relevant needs of the end user. However, it is worth considering the fact that factory designs usually have less error and are capable of performing precise work with minimal tolerance. Therefore, such devices are usually suitable for private use or in small workshops where high-precision holes are not required.

“From the material presented by the author, you will learn how you can independently make a budget drilling machine from an ordinary electric drill.

Every craftsman would like to have such a machine in his household, because in comparison with factory analogues it will cost tens of times less, and if all the spare parts and components are available, then it will be completely free.

The author of this machine is Igor Stasyuk, for which he Thank you very much, shared step by step photos assembling the machine with the people. The design is quite interesting and at the same time simple. Corners and 4 legs are welded onto a base made of a 3 mm sheet of metal; a 500 mm rod made of professional pipe is welded onto this plate. square section, the slider is made of 2 corners welded into a pipe and placed on a lifting column with a gap so that the slider can move up and down along the column. Lifting mechanism it is activated by a cable stretched from the top point to the bottom, and on the slider the cable makes several turns.

So, let's take a closer look at what exactly the author needed to assemble the machine? And also the whole step-by-step process.

Materials

1. sheet metal 3 mm

2. fittings

3. corner

4. cable

5. drill

6. vice for workpieces

7. bolts, nuts, washers, engravers

8. drill clamp

9. paint

10. professional square pipe

11. drill

Tools

1. welding machine

2. grinder (angle grinder)

3. drill

4. file

5. vise

6. clamp

7. caliper

8. ruler

9. corner

10. level

11. sandpaper

12. brush

13. hacksaw for metal

14. emery

The process of creating a drilling machine from a drill.

And so, first of all, the author makes the base of the machine from sheet metal 3 mm, cuts the workpiece using an angle grinder (angle grinder) A in bottom part welds 2 corners and 4 legs from a steel rod or fittings. The length of the legs should be the same so that there is no distortion of the frame.

The corners and legs are welded on.

Making a slider! Take 2 corners and apply them to a professional square-section pipe that will serve as a lifting column and tighten them with a clamp.

It is tacked along the edges by welding in order to simply attach it for now, and only then specifically weld the normal seam.

This is actually how the preparation turned out.

The lifting column is made from professional square-section pipe 500 mm long.

A bracket with a movable shaft is welded onto the slider body, onto which the cable turns will be made.

IN drilled hole thread is cut.

The handles of the lifting mechanism are made of reinforcement.

There is a head on the shaft that will serve as the base for the handles.

And so, 3 handles are welded on for the convenience of raising and lowering the drill through the mechanism.

Installed on a lifting column.

A loop like this is made at the end of the cable.

I hope the lifting principle is clear and without explanation)

A square pipe is welded onto the corner.

This is actually the mount for the electric drill.

Then the drill is installed and secured with a clamp of bolts and nuts.

Now let's go back to the lifting mechanism again.

At the top of the lifting column, a nut is welded and a bolt is screwed into it, a cable is attached to the bolt itself, and when the bolt is tightened and unscrewed, the cable is tensioned to the optimal level.

It is advisable to pre-lubricate the moving components with grease or lithol.

These small vices can be purchased at a hardware store in the tools section.

All parts were sanded by the master using sandpaper and then painted.