How to install vago terminals. Wago terminals

There are 4 ways to connect conductors, which are provided for by the PUE. If we evaluate them from the point of view of convenience and speed of operation, reliability of contact, then the method using terminal blocks (especially in everyday life, when working with internal electrical wiring) - best option, regardless of conditions and local specifics.

This is our story about WAGO products and their main characteristics.

Features of WAGO terminal blocks

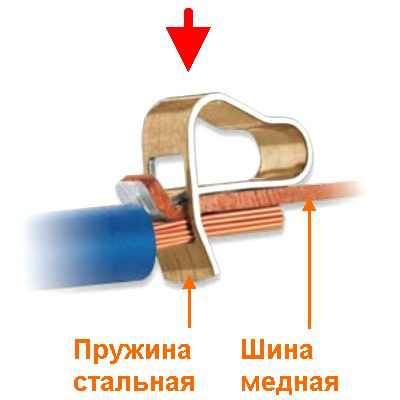

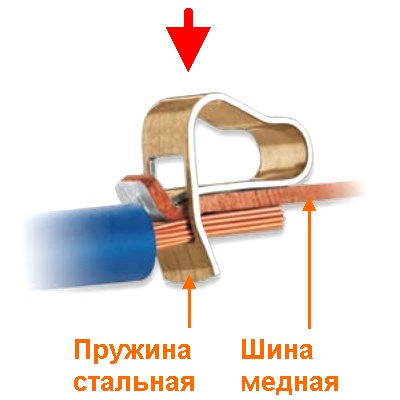

Contact clamps - spring

What is the advantage of such an engineering solution?

Firstly, constant “pressure” compensates for the deformation of the conductor metal (for example, temperature). Consequently, during the entire period of operation, the reliability of contact in the terminal block is not impaired.

Secondly, the springs provide vibration resistance to the connection.

Secondly, the springs provide vibration resistance to the connection.

Thirdly, during the work you will not have to use a screwdriver, as happens when installing “screw” ones and fixing the ends of the wires in them. Those who worked in low light conditions, when installing electrical wiring in hard-to-reach places, will appreciate this advantage of WAGO products.

If we add to this a plus (which is inherent in all terminal blocks) such as the ease of connecting wires made of dissimilar metals (aluminum + copper), then the advisability of using products of this type (with spring-loaded contacts) for electrical installation work is obvious.

Housing made of modified polymers

WAGO terminal blocks withstand exposure to aggressive environments (for example, fuels and lubricants), high temperatures(manufacturing material classified as “hard to ignite”), excess humidity.

Contact groups

For the manufacture of WAGO current-carrying busbars, tinned copper is used (anti-corrosion protection of the contact), springs are made of austenitic steel (chrome-nickel alloying, which gives the alloy elasticity).

CAGE CLAMP

Such design feature terminal blocks allow you to work with conductors of varying degrees of flexibility, and make multiple switchings.

PUSH WIRE

This contact group is distinguished by the specificity of its use. Firstly, the connection of stranded conductors, especially with flexible twisted core, is difficult due to design terminal block springs. Secondly, repeated switching is undesirable. The fact is that after being put in place, the plate “crashes” into the metal of the core and partially damages it.

WAGO terminal blocks of this type are mainly used in areas where frequent (prompt) reconnection of wires is not provided. They are often called disposable products.

Varieties and characteristics

There are a lot of modifications, so it’s hardly necessary to consider the entire range. Below are the most commonly used terminal block options. More detailed information can be obtained at any point of sale, depending on what types of products are in stock.

Series 773

Model -30_. Initially, these products were intended for connecting aluminum wires, for which there is a special paste, improving the quality of contact. There are 4 types of terminal blocks in this group, which differ in size and number of sockets - from two (model -302) to eight (-308).

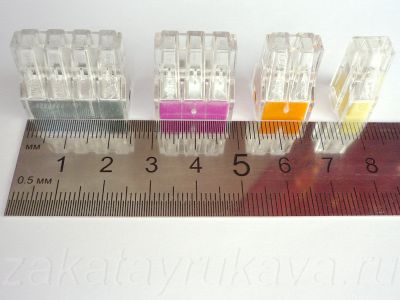

Model -32_. More advanced products, characterized by a translucent body with a colored insert. This allows you to visually monitor the process of connecting the conductor and the quality of fixation of its tip in the terminal block. The designation is identical - for 2 slots (-322), for 4 (-324), for 6 (-326), for 8 (-328).

General characteristics

- Conductor cross-sections (mm2): single-wire – from 0.75; with twisted core - from 1.5 to 2.5.

- Iwork max (A) – 24.

- Temperature range (ºС) – up to +85.

Episode 273

Model -503 allows you to connect up to 3 conductors with a cross-section of 1.5 - 4 “squares” in the terminal block. The presence of paste makes it possible to work with aluminum conductors.

Episode 274

The main purpose is switching circuits lighting fixtures. Models -111 and -122 – with paste, -201 – without it (only for copper wires). Cross section – from 0.5 to 2.5 mm².

Series 222

Models -402 (2 contacts), 403 (3) and -405 (5). Current up to 32 A, cross-section from 0.08 to 4 “squares”.

Series 243

WAGO terminal blocks of this group belong to the “micro” category. Iwork up to 6 A, number of connections from 4 to 8, cross-section - from 0.6 to 0.8.

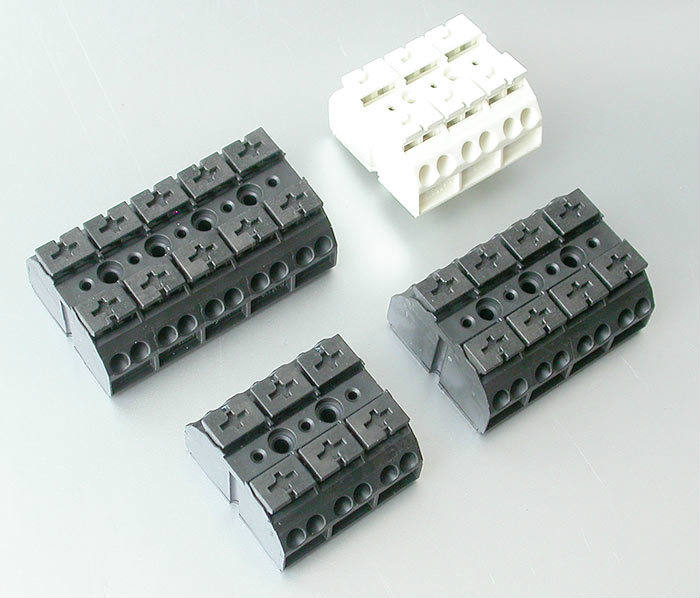

Series 862

The housings can be fixed to any base using self-tapping screws. The number of connected conductors is from 2 to 5 with a cross section of 0.5 - 2.5. Maximum current – 25A. Such terminal blocks are used only when working with copper conductors.

Scope of application

In ~ I circuits with voltages up to 380 V (50 Hz). WAGO terminal blocks provide reliable connection of conductors with copper and aluminum conductors. When choosing a product for installation in a specific circuit, you need to focus on its individual characteristics (see above).

Product cost

It depends on the modification of the WAGO terminal block. Product prices are quite low. For example, products of series 273 (model 202) - 7 rubles per unit, 222-415 - 32 rubles per unit.

This article was written in continuation of the topic started by Alexander Molokov. In European countries terminal blocks WAGO are the most popular way to connect wires. We still view them with great suspicion, although everyone who professionally installs household electrical wiring knows about them. Terminals, connectors, blocks “Vaga”, “vagi” have already firmly entered the vocabulary of the modern electrician.

In this article, let's figure out how WAGO terminal blocks are designed. We will understand using the example of the most popular and universal series - WAGO 222. These terminal blocks are used for connecting and branching copper single- and multi-core conductors. WAGO 222 terminal blocks can be used both for connecting lighting equipment and for installation in distribution boxes.

The terminal blocks use a special flat spring clamp CAGE CLAMP.

In the figure: 1 - The CAGE CLAMP made of CrNi-spring steel creates a high, programmed clamping force, which is automatically adjusted to the conductor cross-section and does not depend on the care of the operating personnel. 2 - CAGE CLAMP applies superficial pressure to the conductor without damaging it. 3 - Carrier rail made of electrolytic copper with a soft, tinned surface, with a gas-tight enveloping of the contact surface of the conductor. 4 - The concentration of the clamping force on the contact surface ensures a high contact pressure.

Materials used for the manufacture of VAGO terminal blocks

Ease of use.

Reduces time for electrical installation (this is especially important for large volumes of work)

Each conductor has a separate terminal location.

The quality of the connection does not depend on the accuracy of the electrician.

When connecting wires using WAGO terminal blocks, the conductors are not damaged.

Reliable protection against accidental contact with live parts of the connection.

Guaranteed reliability of contacts, excluding short circuit and heating at the connection point.

Safety and order in the distribution box.

WAGO catalogs were used in preparing this article.

Page 1 of 3

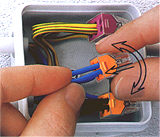

To connect wires internal wiring, professional electricians and home craftsmen are increasingly using WAGO spring terminals. Let's try to find out what is the secret of the success of these electrical products. Let's look in detail at the most common series of terminals and show the right technique their application using the example of assembling a typical distribution box.

General information about the manufacturer and terminal design.

The active development of WAGO (WAGO Kontakttechnik GmbH & Co. KG) began back in 1951. This year, at one of the specialized exhibitions in Germany, WAGO presented its first spring-based terminals. Since then, the company's main focus has been spring contact technology in various areas electronics. In 1973, WAGO produced the first small-sized terminals for distribution (junction) boxes and received permits for their widespread use. Today WAGO is a world leader in the production of spring terminals and connectors of a wide range of products used in electrical wiring and microelectronics.

The main advantages of springs compared to a threaded connection are, firstly, the high vibration resistance of the resulting connection, and secondly, the constant pressure (pressure) applied at the point of contact allows one to compensate for the plastic deformation of the wire metal.

The terminals allow for compact electrical installation certified according to international standards, allow multiple reconnections of wires, and have technological holes for accessing the current-carrying busbar with a probe measuring instrument. Almost all series of WAGO terminals do not require the use of specialized tools during installation.

The contact groups of the terminals consist of two parts: a current-carrying busbar and a spring. The busbar is made of tinned copper; thanks to tinning, protection against corrosion and an increase in the electrical contact area are provided. The flat spring has a complex shape and is made of austenitic steel with chromium-nickel alloying, which allows achieving the necessary elasticity.

The electrical insulating housing of the terminals is made of modified polyamide grades “PA 6.6” and “PA 6.4” or polycarbonate. These are low-flammability, self-extinguishing materials with a wide range of operating temperatures, resistant to fuels and lubricants and atmospheric influences.

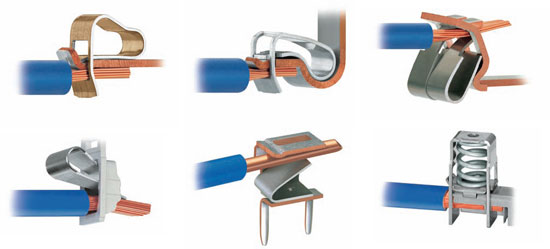

Two types of contact groups.

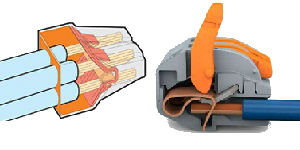

PUSH WIRE®

A flat spring of this type of contact group performs two functions: it exerts the necessary pressure on the wire, pressing it against the current-carrying busbar, and prevents spontaneous disconnection of the wire due to its special location. The spring is located at a gentle angle to the wire, so removing the wire from the contact group is much more difficult than inserting it. When removing the wire, the spring with its edge (end) crashes into the wire. A special feature of the PUSH WIRE type contact group is that it does not require frequent removal of the wire, as this leads to damage to the surface of the wire and can sometimes cause spring deformation. When connecting a wire, the spring provides little resistance, but it is often enough to make it difficult to insert a stranded wire. Connecting a stranded wire of a high class of flexibility, without using a rigid tip, is completely impossible.

Contact group PUSH WIRE.

CAGE CLAMP®

This design of the contact group was developed taking into account repeated reconnection of the wire. The flat, curved spring has rectangular window for inserting a wire on one side and a current-carrying busbar on the other. By elastic force it presses the wire and the busbar against each other. When pressing on the top of the spring, the window opens slightly, and it becomes possible to insert or remove the wire with zero effort. Thanks to this, wires of any flexibility class can be easily inserted into the CAGE CLAMP type contact group.

Contact group CAGE CLAMP.

The red arrow shows the point and direction of application of force to compress the spring to open the window before removing or inserting the wire.

Types of wires.

WAGO terminals, depending on the model, are used to connect electrical wires certain types and range of sections. The picture shows full list wires allowed for connection in construction mounting terminals one model or another.

![]()

1. Aluminum single wire; 2. Copper single wire;

3. Copper stranded; 4. Multi-wire tinned;

5. Multi-wire in a sleeve tip;

6. Stranded with pin end.

WAGO construction and installation terminals for distribution boxes.

Series 773-30x.

This series includes the terminals that appeared on Russian market one of the first and therefore today are considered evolutionarily obsolete. The terminals were primarily developed for connecting aluminum wires, as it says inside, but they allow the use of copper wires. The lineup consists of four products in a dark gray polyamide housing.

Technical characteristics of WAGO 773-30x series terminals.

| Terminal model | 773-302 | 773-304 | 773-306 | 773-308 |

|---|---|---|---|---|

| Number of inputs | 2 | 4 | 6 | 8 |

| Appearance and sizes |

|

|

|

|

| Presence of quartz vaseline paste | Yes | |||

| Type of contact group | PUSH WIRE |

| Types of connected wires |

Single wire, |

|

24 A at 300 V ( B.V.) 24 A at 400 V ( ABS, CCA, FIMKO, GL, LR, NEMKO, RMR, SEMKO) |

|

| 85°C |

773-30x series terminals.

On the terminal housings there are symbols that remind you of the product model, wire stripping length, maximum current strength,

maximum operating voltage and others.

At the rear end of the terminal there is one or more holes (depending on the model) for the probe of the measuring device (photo on the left).

Availability of filling the terminal with quartz vaseline paste

easily determined visually (photo on the right).

The stripping length of the wire can be controlled by markings on the terminal itself.

Opening WAGO terminals using a thin flat screwdriver (doable for many series of terminals). In this way, you can remove a piece of wire from the inside that remained there after it was unsuccessfully disconnected.

![]()

WAGO terminals allow you to connect wires made of dissimilar metals:

in the PUSH WIRE type contact group of the WAGO 773-306 terminals there are both copper and aluminum wires.

Series 773-32x.

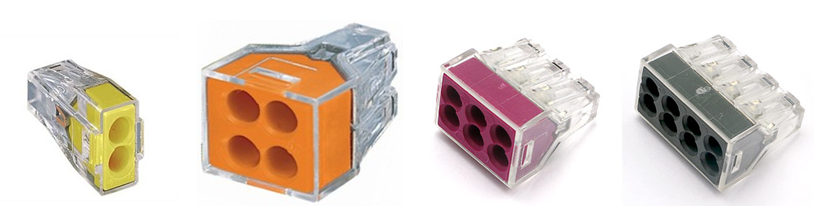

Here we have terminals that are improved compared to the previous series. Their main feature is a partially transparent body, which makes it possible to visually assess the depth of wire insertion. All terminals in this series are supplied without quartz vaseline paste. The model range consists of four products in a polycarbonate case with multi-colored inserts. The color of the insert is tied to the terminal model.

Technical characteristics of WAGO 773-32x series terminals.

| Terminal model | 773-322 | 773-324 | 773-326 | 773-328 |

|---|---|---|---|---|

| Number of inputs | 2 | 4 | 6 | 8 |

| Appearance and dimensions |

|

|

|

|

| Presence of quartz vaseline paste | No | |||

| Type of contact group | PUSH WIRE |

| Types of connected wires |

Single wire, stranded low flexibility class |

| Permissible cross-sections of single-wire wires | 0.75 - 2.5 sq.mm (18 - 12 AWG) |

| Permissible cross-sections of stranded wires | 1.5 - 2.5 sq.mm (16 - 12 AWG) |

| Maximum operating current at specified voltage (according to test standard) |

20 A at 600 V (UL listed, CSA) 24 A at 300 V ( B.V.) 24 A at 400 V ( ABS, CCA, GL, KEMA, LR, NEMKO, ?VE, RMR, SEMKO) |

| Maximum long-term operating temperature | 85°C |

773-32x series terminals.

For quite some time now, spring terminals called spring terminals have entered our lives. "WAGO". At the moment, this name has become a common noun, as it once became common noun Xerox. Nowadays, few people think about the fact that this is the name of the company and you can often hear from people’s lips the word “vagi”, already transformed into the Russian language.

So what exactly is "WAGO"?

Firm "WAGO"(Germany) is a world leader in the production of terminals and connectors using spring connection technology. WAGO terminals and connectors are widely used in both household electrical wiring and industrial installation in places requiring increased reliability and vibration resistance.

Currently, there is a wide range of WAGO products on the Russian market, but the most famous and widely used in everyday life are construction express terminals (terminals for household electrical wiring).

WAGO construction express terminals based on a flat spring clamp allow you to reliably connect solid/light copper or single-core aluminum conductors in any combination without the use of tools. They provide reliable and compact electrical installation of conductors in distribution boxes.

Rules for using WAGO express terminals

|

|

|

|

| Removing insulation. | Connection. | Examination. | Disconnect. |

| Remove the insulation from the connected conductors by 12 - 13 mm. | Insert the stripped conductor all the way into the free terminal space. | Use the holes in the terminal housing to check the electrical parameters of the circuit. | If it is necessary to disassemble the connection, pull out the conductor while simultaneously rotating it slightly |

It was WAGO that was the first to realize the idea of connecting electrical conductors not with a screw, but with the force of a spring. All WAGO terminals meet the following criterion: maintenance-free, vibration-resistant terminal connections, independent of the force applied by the installer.

Main advantages of spring technology:

The WAGO spring terminal adapts to the cross-section of the conductor, so the clamping force is optimal and the conductor is not damaged;

The connection at the contact point is gas-tight;

High impact and vibration resistance;

Significant reduction in installation time;

The quality of the contact does not depend on the qualifications of the installer (the conductor is connected as follows: a screwdriver is inserted into the technical hole to press out the spring → the conductor is inserted into the WAGO terminal → the screwdriver is removed, after which the spring automatically clamps the conductor);

Subsequent Maintenance No WAGO terminals required.

Source material for WAGO terminals chromium-nickel spring steel and special tinning electrolytic copper are used. And as carriers of conductive elements, polyamide (PA 6.6 and PA 4.6) and polycarbonate (PC) are predominantly used as dielectrics.

Maximum technical specifications WAGO terminals:

Guaranteed maximum current flow 232 A;

Guaranteed maximum voltage 1,000 V;

Maximum conductor cross-section 95 mm2;

Permissible peak voltage 8 kV.

WAGO produces terminal blocks in three directions:

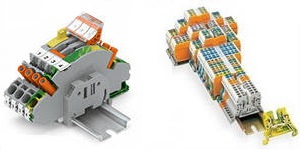

1. Feed-through terminal systems

2. Terminals for printed circuit boards and modular plugs

3. Connection terminals and modular plugs

According to the type of spring used, WAGO terminals are divided into:

Flat-spring terminals: suitable for single-core conductors with a diameter of 0.5 to 4 mm2, most often used in building electrical installations, building security systems and telephony.

CAGE CLAMP terminals: ideal for both solid and stranded conductors. When using CAGE CLAMP, it is not necessary to use end sleeves/lugs for a quality connection.

Terminals based on the FIT-CLAMP: it is based on a mortise contact, so preliminary stripping of insulation from the conductor is not required, which further speeds up and simplifies installation.

According to the installation method in the equipment, they are produced following types WAGO terminals:

For installation on support rails type DIN 35.

For installation on mounting panels.

For mounting on printed circuit boards.

For all terminals, WAGO produces markings, mounting accessories, tools, and individual core and cable markings.

Terminal blocks Wago 773 and Wago 273

Wago terminals 773 and Wago 273 are designed for connecting and branching single-core conductors made of copper and aluminum or stranded copper wire with tip in electrical circuits alternating current with a frequency of 50 Hz and voltage up to 380 V. Terminal blocks Wago of these series are used in distribution boxes.

Main characteristics: Wago 773 terminals; 273

| Name | Current (A) | Number of connected wires | cross-section range (mm?) | Availability of contact paste |

| Wago 773-322 (photo 1) | 25 | 2 | 1,0-2,5 | without paste |

| Wago 773-324 (photo 2) | 25 | 4 | 1,0-2,5 | without paste |

| Wago 773-326 (photo 3) | 25 | 6 | 1,0-2,5 | without paste |

| Wago 773-328 (photo 4) | 25 | 8 | 1,0-2,5 | without paste |

| Wago 773-302 (photo 5) | 25 | 2 | 1,0-2,5 | with pasta |

| Wago 773-304 (photo 6) | 25 | 4 | 1,0-2,5 | with pasta |

| Wago 773-306 (photo 7) | 25 | 6 | 1,0-2,5 | with pasta |

| Wago 773-308 (photo 8) | 25 | 8 | 1,0-2,5 | with pasta |

| Wago 273-503 (photo 9) | 25 | 3 | 1,5-4,0 | with pasta |

Terminal blocks Wago 224

Key Features: Wago 224 Terminals

Terminal blocks Wago 222

| Wago 222 terminals are designed for connecting and branching single-core and stranded copper conductors in AC electrical circuits with a frequency of 50 Hz and voltage up to 380 V. For aluminum conductors, these terminals are filled with conductive paste. Wago universal terminals are used both for connecting lighting equipment and for installation in distribution boxes. | ||

| ||

Main characteristics: Wago 222 terminals

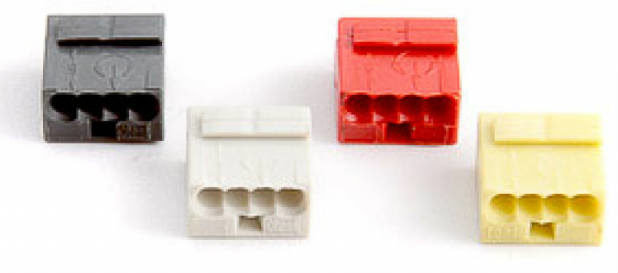

Terminal blocks Wago 243 series Micro

Main characteristics of Wago 243 terminal blocks

| Name | Current(A) | number of connections | Conductor cross-section (mm?) | Color |

| Wago 243-204 | 6 | 4 | 0,6-0,8 | dark grey |

| Wago 243-304 | 6 | 4 | 0,6-0,8 | light gray |

| Wago 243-504 | 6 | 4 | 0,6-0,8 | yellow |

| Wago 243-804 | 6 | 4 | 0,6-0,8 | red |

| Wago 243-208 | 6 | 8 | 0,6-0,8 | dark grey |

| Wago 243-308 | 6 | 8 | 0,6-0,8 | light gray |

| Wago 243-508 | 6 | 8 | 0,6-0,8 | yellow |

| Wago 243-808 | 6 | 8 | 0,6-0,8 | red |

| Wago adapter | number of terminals | |||

| Wago 243-112 | 4 | |||

| Wago 243-113 | 6 |

Terminals for construction

electrical installation company VAGO ( Germany) based on flat spring clamps allow secure connection single-core / low-core copper or single-core aluminum conductorsin any combination without using tool . They providereliable and compact electrical installation conductors in distribution boxes . VAGO terminals are full special contact paste, automatically removing oxide film with aluminum conductor Andprotecting him from repeated oxidation . Aluminum conductors withclearly visible signs of strong oxidation ( with a very darkened coloring) recommended before clean connection mechanically.Advantages of electrical installation using construction

- VAGO mounting terminalsreliable connection

single-core/ low-core copper and/ or single-core aluminum conductors, A also mixed electrical installation;each conductor has a separate

terminal location;connection quality does not depend on battery

electrician's army;conductors are not damaged

;reliable protection against accidental touchingconnection to live parts of the connection;

it is possible to measureelectrical parameters of the circuit withoutconnection isolation violations;

guaranteed contact reliability, eliminating short circuit and disconnectionheating at the connection point;

safety and order in

distribution boxHi all. Connection terminal blocks wago These are devices with which wires are connected to make branching in a junction box, electrical panel and other devices. Usually people are looking for wago spring or feed-through terminals, so we’ll talk about them. In the article you can learn how to use vagon terminal blocks, mount them, where to look at the technical specifications in order to select the ones that are suitable for the load. vago mounting terminals. Find out the opinion of a specialist and leave your feedback. Also photos, videos.

Terminal blocks WAGO, manufacturer

WAGO Kontakttechnik GmbH- developer company - largest producer screwless terminal connectors for various types guides in Germany. This company was founded in 1951, and since then has gained enormous popularity and demand for its products. The idea behind the creation was to find a good alternative to the usual screw connection of wires and cables. This is how it was developed spring connection system , where the expression “wago spring terminal blocks” comes from. Today, of course, this is not the only direction of WAGO Kontakttechnik GmbH, there are others.

Vago terminal blocks, application:

how to use and install

Their use allows fast and convenient connect wires and cables during installation. Vago connecting terminal blocks have gained great popularity since their appearance on the market. Today they are used in construction, in production, and also in everyday life. Their installation does not cause problems, but on the contrary, simplifies the installation process. But not everything is so simple, of course.

In everyday life, the use of vago terminals was focused on the 222 series, with 3 or 5 connections. They are used to connect wires in distribution boxes for lighting, alarms, etc. How to use wago terminals, drawn on their body, insert the stripped core into the terminal block socket, clamp it, if the series is 222, you’re done.

Feed-through terminals WAGO

In industry and enterprises, wago feed-through terminals mounted on a DIN rail are most often used.

Advantages of Vago terminal blocks

Here I will not go into details, since you can find at least some advantages in everything. I'm telling you this as a salesman. I’ll just say what I highlighted myself - it’s the simplicity and speed of installation and dismantling if necessary, also aesthetics and beauty. If anyone has anything to add, please leave a review in the comments. Just don’t write about the reliability of the connection, vibration resistance and the like, since it’s more reliable screw clamp spring terminal blocks cannot be used.

WAGO mounting terminals:

technical specifications, types, types, photographs

If you are interested in what types of wago mounting terminals there are, then it is best to find out about it on the manufacturer’s website - www.wago.com Everything is very well written there, a convenient site. Their 700 page catalog contains more than 10,000 items, with all technical characteristics, areas of application, types and photographs, be it spring or feed-through terminal blocks of the car.

WAGO terminal blocks, reviews

Increasingly, car connecting terminals are used in everyday life, but in everyday life we usually forget about the word “ service”, and power consumption increases rather than decreases, since without electricity there is nowhere, electrical appliances create comfort and convenience to which we are already very accustomed. I studied many sites on the Internet before writing this post and came to my conclusions. What do electricians say?

- Wago mounting terminal blocks are great! Fast, convenient, reliable!

Certainly! Who would doubt it, because it simplifies your work, I agree. Vago spring terminals have all the necessary certificates of conformity, safety, etc. But what do those people who service houses, apartments and other similar premises say?

Let's look and listen to someone who really works with this, for whom the word faster does not apply at all. In touch Sergey Panagushin, a reader and like-minded person of the blog, a housing office employee in the city of Izhevsk, a specialist with work experience:

Well, my opinion is wago connection terminals it's really, useful devices, but only in construction and production, where there is service staff and the word "service" is applicable electrical circuit" Also indispensable for temporary power supply, repairs and construction. At home Vago mounting terminal blocks not good, screw connections or twists are more reliable, ideally with welding. Plus it will cost less. But if you still decide to use the vago spring terminals, then I recommend providing current reserve.

If you have your own opinion about wago terminal blocks, leave reviews in comments.