How to solder a silver spoon at home. Methods for soldering gold at home.

Silver is a precious and noble metal used for various purposes, including making jewelry. For example, a chain made from it is attractive and classic product, which can be worn as a bracelet or necklace. True, despite the strength of silver, jewelry made from this metal can be quite fragile and even break. But many of them are easy to restore; the main thing is to know how to solder silver at home.

Features of technology for joining metal products

To connect them together, a more fusible metal is used. The soldering process may vary depending on the conditions in which the product will be used and the type of metals to be fused. For example, jewelry repair and bonding printed circuit boards in electronics are performed different ways. However, many people are more interested in how to solder silver at home.

Selection of material for joining metal products

Silver can be purchased at any hardware store. It is better to give preference to refractory substances whose melting point is at least 240 °C. In this case, it is advisable to use specialized soldering paste or alloys marked PSR-2.

You can make your own solder for joining silver products. It must include the following metals:

- zinc 30%;

- copper 25%;

- silver 45%.

These components can be melted using submerged arc. The resulting mixture must be poured onto a substrate, and then passed through a rolling machine to create plates about 0.5 mm thick.

To create parts, strips about 1-3 mm wide are used. Pieces of the required length are cut from them. During soldering, air is exposed to the area being joined. To prevent oxidation and other negative reactions, it is necessary to use flux (colophonium). When the solder is heated, it is moderately distributed throughout the metal, isolating the welding area.

How to solder silver with a soldering iron?

Before silvering at home, you need to prepare flux and solder in advance. Often when connecting components containing silver, 60% tin and 40% lead are used. This solder begins to melt at a temperature of 180 °C.

But before you start soldering silver, you should clean the surfaces of the products and remove from them the film of oxides that has appeared over time. In such a situation, the solder ensures internal fusion with the silver.

The soldering area of the silver product must be well heated in order to exceed the connection using a powerful soldering iron. On top of that, it is recommended to isolate it from oxygen air. To achieve the best result, flux will help to create a flux above the junction of the component parts. protective film. When the solder melts, colophonium will be distributed evenly over the metal plane.

When using a soldering iron to join silver jewelry, it is necessary to use high-temperature solder that matches the test of the metal.

Joining silver items with a gas torch

Before you learn how to solder silver with a cassette torch, you need to make sure there is a fan to ventilate the room before starting work. To reduce the amount of smoke generated during the soldering process with a torch, you will have to not only turn on this device, but also open the windows. When joining metal jewelry, it is important to keep strong jets away from the work area, otherwise the cooling procedure may lead to problems during soldering.

Before soldering silver at home with a gas torch, you will need containers of water to rinse the products after bonding. Moreover metal parts must fit entirely into them.

When decorating, it is best to use a torch that has a flat tip, since a pointed one will quickly dissipate heat. The metal joining process requires the following steps:

How to solder silver with tin?

Soldering silver jewelry with tin is rarely carried out, since their repair in the future can lead to dire consequences. For example, when a jeweler is not aware that the product was previously held together with this metal, he can use ordinary high-temperature solder to solder it. These actions will lead to the fact that it will simply burn out.

Do not use too much solder to avoid lumps. If they do form, they must be removed with a nail file. If an acid solution spills on clothing or skin, immediately rinse the area with plenty of cold water.

If you happen to damage your loved one gold decoration, then laser soldering of gold will be required.

Repair of broken jewelry can be carried out in a specialized workshop, and a number of small defects can be eliminated with your own hands.

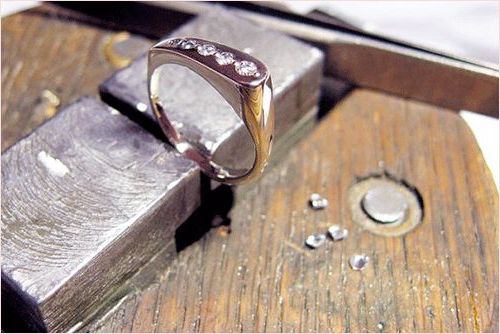

A cracked or crushed ring, of course, is almost impossible to repair at home - soldering on the visible part of the jewelry will result in a rough solder seam and, possibly, discoloration, which is difficult for a beginner to prevent.

But soldering a braided chain by connecting broken links is quite possible.

In the article we will look at how to solder gold and repair gold jewelry at home with your own hands and show an instructional video.

How to do soldering?

Information that, starting from the early Middle Ages and the emergence of the first production workshops, people used soldering to join (alloy) two parts of the same precious metal, came to us with preserved jewelry, on which a rough seam is clearly visible.

Gold jewelry of the Middle Ages was massive and, therefore, some unevenness of the seam was not noticeable.

As before, there and now the connection of two metal surfaces carried out using a third, which melts at a much lower temperature.

By heating all three surfaces (using a torch or laser), the low-melting surface melts and spreads over the parts to be joined.

Once solidified, the soldering forms a hard bonding layer of alloy, which is then ground to make it invisible.

The low-melting alloy surface that creates the bonding layer is called solder and is usually produced in the form of rods.

Each metal requires its own solder and even several.

When the edges of the surfaces to be soldered heat up, an oxidizing strand appears on them - an oxide that interferes with the strong adhesion of the welded layer to the base.

Moreover, it not only worsens the connection, but can lead to an instant break after cooling.

To prevent this, flux is used - a substance that, when heated, neutralizes the acidic film.

The flux is not only selected for each metal or alloy, but also depending on the further use of the item, the load on the solder joint, solder and a number of other parts, the flux must be different.

If solder for melting gold can be purchased or made independently (for example, from silver, copper, brass and 880-grade dental crowns), then you only need to buy flux.

The solders, which were used back in Kievan Rus, contained mercury or cadmium.

Nowadays it is extremely rare to find such solders and, probably, it would be redundant to say that they are very toxic and it is better not to use them.

According to the method of creating the connecting layer, laser soldering of the alloy and soldering, which uses a gas burner at home, stand out.

How the burner works:

- We prepare or purchase solder depending on the gold standard;

- Apply flux and wait until the flux spreads along the edge of the surface. Choose only the appropriate flux. Distribute the flux beyond the soldering area. This is done so that the prepared area is slightly larger than the soldering itself - it may have to be expanded during the soldering process;

- It will take feka. She represents bent tube with a hole at the end through which the burner supplies a thin stream of gas flame. Through inner surface compressed air is supplied;

- Let's join the two broken parts and heat them up. blowpipe, add solder until it stops shining, and leave it to cool, after which we clean it with a file.

Gas soldering helps restore gold; if soldering is done carefully, the seam will not be visible. Soldering, which uses a torch, can be done independently.

There are also professional ways gold repair, which are used in jewelry workshops, for example, laser soldering.

It will allow you to repair a torn piece of jewelry completely unnoticed, regardless of the complexity and location of the break, gold standard and other conditions.

Laser soldering is done using laser beam guided by special equipment.

It is quite expensive and there is no need to purchase it for one-time soldering of gold.

Laser soldering has a number of advantages over gas soldering:

- Spot heating of the surface;

- No need to use flux;

- Inability to overheat the place where parts are soldered. Overheating is often a critical error when soldering gold. As a result, the adhesive seam will change color and restore the original color chemical methods will not work. If this happens, then the entire product must be coated with an additional layer of gold using the electrochemical method;

- Soldering is possible for areas of several hundredths of a millimeter;

- Absent mechanical damage surfaces, the laser acts accurately, pointwise and without contact with the surface;

- The method allows you to prevent foreign particles from entering the soldering area.

Laser soldering is performed without changing tools; all necessary settings are adjusted on the control device.

It is imperative to use it when the decoration has a complex design, a complex break, or when it is not possible to do gas soldering yourself.

Electroplated gold

Of course, gold jewelry is very high price. In order to put cheaper analogues on sale, gilding of base metals was invented.

Costume jewelry is inexpensive jewelry. They are usually made from bronze, copper, brass and an alloy in varying proportions of zinc, tin, and iron.

Metals and their alloys in the final product will differ in strength and color. IN Lately to reduce the cost technological process They even began to make jewelry from plastic.

The result is a nice little thing that will easily lose the color of the coating under the influence of air and humidity, oxidize, or even break completely.

To ensure that jewelry is used for a long time without loss decorative properties, it is sprayed, most often from precious metals - gold and silver.

Forming a precious surface on a base metal can be done mechanically and galvanically.

At mechanically gold is applied in the thinnest plates using glue or other fixatives.

The result of this titanic work is Gold leaf, which is commonly used for church domes.

A gold layer can be electroplated using an electric current.

The part is placed in an electrolyte solution between two gold plates, the plates are connected to a positive current source, and the electrically conductive wire on which the decoration is suspended is connected to a negative one.

The current removes tiny particles of gold from the plates and deposits them on a negatively charged particle.

Electroplated layer can be applied different thicknesses, it all depends on the processing time. The minimum time for the required thickness of the deposited layer is 30-40 minutes.

The result is ours cute decoration became gold and, of course, more wear-resistant.

The attitude towards galvanically made gold is twofold - some consider such jewelry to be cheap, but for others it is a completely justified way to produce jewelry.

You can electroplate gold at home. A similar experiment, however, not with the use of gold due to its high cost, and with nickel or copper, are demonstrated in high school chemistry classes.

As we have discussed, technologically soldering gold surfaces is not difficult.

Mastering gold soldering is quite difficult only because the cost of solders and consumables is very large, besides, it is unlikely that you will deliberately spoil the jewelry in order to work on soldering on it.

For those who want to learn how to solder gold surfaces, we can recommend mastering the soldering of small copper parts (radio components or wiring) and, having acquired solid skills in the soldering process itself, take on the repair of gold jewelry.

- What will be needed for repairs?

- Work order

- How to solder silver parts with a soldering iron?

From time to time, silver items require repairs, and the question arises: how to solder silver at home? After all, for several centuries, humanity has been using silver products. Spoons, forks, bracelets, chains, boxes and rings decorate our lives and emphasize the individuality of the owner.

Tools and materials for soldering: a – regular soldering irons, b – electric soldering iron, c, d – irregular shape soldering iron, d - casting solder into a form convenient for work.

You can entrust the repair of your favorite item to a professional or have it done necessary actions yourself, with your own hands. For last option You will need to master technological techniques, procedures and apply in practice information on materials science and other necessary information.

How to solder silver at home?

Soldering any metals requires knowledge of physical and chemical properties material. Silver melts at a temperature of 960ºС, this is the average value for metals used in manufacturing jewelry. For example, the temperature required to reach the melting point of copper is 1083ºС, and for gold – 1063ºС.

Preparing the soldering iron for work and cleaning the surface: a – heating the soldering iron with a blowtorch, b – methods of attaching the soldering iron to a blowtorch, c – stand for the soldering iron, d – tinning the soldering iron on a brick.

IN modern production solders containing silver are an important, integral component of the technological process, since welds soldered silver solder, guarantee durability, high density and corrosion resistance. Anti-corrosion should be recognized as the most significant quality. When the requirements for strength and corrosion resistance increase, it is necessary to use solders with a high silver content. In some cases, soldering with solder with a 70% silver content is used.

Solder for silver is purchased in specialized stores. It is preferable to use refractory solder (melting point above 240ºC), use an alloy marked PSR2 and PSR-2.5, or use a specialized soldering paste.

You can also make your own solder. Silver-copper-zinc and silver-copper-cadmium-zinc solders are used. Most optimal composition– 45% silver, 25% copper, 30% zinc. The components are melted in a submerged muffle furnace. The finished mixture is poured onto the substrate, after cooling, the alloy is passed through a rolling machine until sheets approximately 0.5 mm thick are obtained. When soldering, strips 1-3 mm wide are used, from which pieces of the required length are cut.

It is not recommended to use formulations containing cadmium at home, as cadmium vapor will cause health problems. During the soldering process, the joint is exposed to atmospheric air. To prevent oxidation and other negative reactions, flux (colophonium) is used. As the solder melts, the flux is evenly distributed over the surface of the metal and insulates the welding area.

Soldering techniques: a – soldering an open seam with a hammer soldering iron, b – heating the surfaces to be soldered with an electric iron, c – soldering sheet metal, d – soldering of wires, e – soldering of pipes with an end soldering iron, f – method of sealing holes in pipes, g – tinning of wire ends.

At home, you can use a simple flux for soldering silver alloys - a mixture of equal parts of borax (sodium tetraborate) and potash. Potash can be replaced with baking soda or technical soda. Sometimes 1/10 table salt is added. Borax is an aqueous solution and needs to be dried. It's drying on the burner kitchen stove in a porcelain type vessel chemical container or evaporation cups. Dry over low heat.

Hot borax forms bubbles, which are pierced with a metal rod to destroy them; the mass must remain in the container. After the evaporation process is completed, the borax is immediately removed from the heat to prevent melting. After cooling, the resulting crystals are ground in a mortar and mixed with potash.

After soldering is completed, the flux is removed from the surface of the repaired product using a heated weak solution acids. For blackening, a hot solution of liver sulfur is used. Sulfur liver is a mixture of sodium or potassium polysulfides, made by fusing potash or soda (two measures) with sulfur (one measure). The finished sulfur liver should be stored in a sealed dry container; a solution should be prepared immediately before use, as it retains its properties for 24 hours. The saturation of the solution depends on the desired result and is selected individually.

They are used to connect small jewelry parts. Such certainty when choosing the main tool is associated, first of all, with convenience: to operate a gas burner, you only need an ordinary gas cartridge, and you will be pleased with the quality of the work performed.

Return to contents

What will be needed for repairs?

- insulating fireproof base (brick or asbestos board);

- silver solder;

- flux;

- pickling acid solution;

- sulfur liver;

- small brush;

- wire cutters;

- tweezers;

- gas-burner;

- copper tongs;

- clean cloth.

Return to contents

Work order

Parts intended for soldering are placed on a refractory base. All elements must be rigidly fixed relative to each other. Clamps are used different designs and refractory wire (nichrome). Please note: the smaller the gaps in the welding area, the more beautiful and high-quality the connection will be.

The working surface of the parts to be soldered is thoroughly cleaned, and any remaining residue is removed. for a long time oxide films. Pay attention to the complete absence of contaminating components - this is the only way to achieve a high-quality internal connection. Fat-free elements are coated with a thin layer of flux. You can simply pour in the flux or prepare the required amount of slurry with water immediately before soldering. The gruel is applied with a brush.

Gas torch for soldering metals: 1 – inner tube, 2 – outer tube, 3 – hole, 4 – star, 5 – extension.

Soldering. A piece of solder is placed at the welding site. The amount of solder is determined by location; it is convenient to use pieces measuring 2x2 or 2x1 mm. A strip of solder approximately 0.5 mm thick is divided into parts required size. Nippers or side cutters are used.

The gas burner is connected to the product from the side. Warm up the welding area carefully. Make sure that the flow of hot gas does not blow away the solder and flux, and also control the uniformity of heating. After the flux melts, the flame gradually increases until the solder forms a solder joint. If there is not enough solder, carefully add solder and flux.

If a crack needs to be filled, "light" silver solder with reduced silver content can be used as it melts at a lower temperature. To join two pieces together respectively, use “medium” or “hard” silver solder with high content silver to create a stronger connection.

Final processing. The product is cleaned of flux. Excess solder is removed with sandpaper or a file. The surface is blackened or lightened with an acid solution.

In some cases, they try to solder silver with tin-lead solder. This method can be used only once in a critical situation; during repeated repairs, the elegance of the item may be lost: under such circumstances, the product will simply burn out, and the master will not be to blame for this.

Be sure to warn the jeweler about using solders that do not contain silver during repairs.

Connecting parts or repairing cracks in jewelry and electrical components requires the use of different materials and technologies, based on the choice of tool (soldering iron or gas burner). Before soldering silver at home, you should familiarize yourself with technical parameters process:

- The optimal melting point of silver is 960 degrees. (products made of copper and gold melt when heated to 1083 and 1063 degrees, respectively).

- Silver solders are used for work: PSr-25, PSr-10, PSr-12. Their markings include alphabetic and numeric characters (they indicate percentage silver in solders). With increasing requirements for strength and resistance to corrosion, an increased silver content in solders is required, up to 70%. For example, the PSR-12 alloy allows you to create high-quality seams on pipes, manifolds, fittings and other products containing at least 58% copper. Among contemporaries, the POS-40 alloy, consisting of 40% tin and 60% lead, is popular. The POS-40 substitute includes 2.5% silver, the remainder being lead.

- When working with jewelry important criterion It is advisable to use high-temperature solder corresponding to the metal grade, or low-grade materials with the inclusion of silver in the composition. The use of tin to join silver parts can cause further difficulties during repairs. An uninformed technician may begin soldering using high-temperature solder. As a result, the product will burn.

Soldering silver parts using a soldering iron

Soldering involves creating permanent connections metal products, using silver and low-melting materials (their melting temperature is lower than the main workpieces).

Features of the work:

- When soldering electronic systems with the inclusion of silver in the composition, you should use POS-60 solder, with a melting point of 180 degrees. Tinol is found on the market in the form of thin tubes filled with resin. It is used as a flux that prevents the possibility of oxide formation on the metal.

- Further protection work surface parts intended for soldering require removal of the oxide film that has formed over a long period of time. This will ensure that high quality internal connections between the material and silver are achieved.

- The area to be joined should be heated to a temperature exceeding the upper melting limit of the solder. Due to the low power of the soldering iron, difficulties may arise when heating products with low thermal conductivity.

- To ensure high-quality protection of connections from air penetration, you should use colophonium, which can create a protective film in the area where soldering is planned. During solder melting, the flux is evenly distributed throughout the metal coating.

How to prepare a soldering iron?

When connecting the soldering iron to the network for the first time, smoke may be generated. This indicates the burnout of oils, which serve to preserve the device. It is enough to ensure ventilation of the room. When preparing the tip, it is possible to create it in the form of a screwdriver, which will give density and high resistance to wear. To create sharp or truncated cones, tetrahedral pyramids, and angular bevels on one side, you can sharpen the soldering iron with emery or a file. Nickel coatings will protect copper from oxidation. For soldering small parts optimal solution the tips will become sharp conical or knife-shaped.

Instructions for working with a soldering iron equipped with an uncoated copper tip require tinning it to prevent oxidation and wear. Otherwise, a thin layer of scale may form and the solder will not stick to it. Tinning the “tip” is carried out by heating the soldering iron to operating temperature, touching the “tip” to the rosin, melting the solder on it and rubbing it on a piece of wood. These precautions help reduce gradual corrosion by flux and dissolution of the solder tip.

Solder selection

Solder for silver is sold in specialized stores. Refractory options with a melting point of 240 degrees are preferred. Alloys marked PSR2 and PSR-2.5 or specialized soldering paste are recommended.

You can make your own solder yourself. They include 45% silver, 25% copper and 30% zinc. Melting of the components is ensured in a submerged arc muffle furnace. The finished mixture is poured onto a substrate and then passed through a rolling machine, which makes it possible to obtain leaves 0.5 mm thick. For soldering, strips 1-3 mm wide are used, from which pieces of a given length are cut. During the soldering process, the area being connected is affected by atmospheric air. Flux (colophonium) will prevent oxidation and other negative reactions. When the solder is heated, the flux is evenly distributed over the metal coating, insulating the welding area.

Melting technique using a soldering iron

There are two main methods of soldering with a soldering iron:

- Supplying (draining) solder onto products from the tip of the soldering iron.

- Supplying solder directly to the surface to be treated.

In any case, it should be done preliminary preparation parts to be soldered, install them and fix them in their original position, heat the tool and moisten the joint with flux. The further procedure is determined by the choice of technology.

When feeding solder from a soldering iron, you should melt a small amount of solder on it (until it is held at the tip) and press the “tip” against the products being connected. The flux will boil and evaporate, and the heated solder will transfer from the soldering iron to the seam. The solder is distributed with the tip along the seam.

The lack of solder will be indicated by the metallic shine of the tip. If there is a noticeable change in the shape of the sting, one can judge that it is too large quantities solder.

When applying solder directly to the seam, the parts should be heated to soldering temperature, and the solder should be applied to the product or butt joint between the heated tip and the part. During the melting process, solder fills the joints between the products being joined. The choice of technology is determined by the type of work. The first option is suitable for small jobs, the second method is for large items.

If the solder does not flow, but smears, the parts are not warmed up enough, you should use a more powerful device or heat the soldering iron to the specified temperature.

It is not recommended to apply large amounts of solder. For creating high-quality soldering an optimal volume of material should be provided in the area to be joined, ensuring a slight concavity of the seam. If there is too much solder, the right decision will be its removal.

The quality of the junction is indicated by its shade. Top quality- the junction has a bright shine. Insufficient level temperature gives a granular structure, a spongy surface - a defect. Burnt solder has a dull tint and low strength.

The use of active (acidic) fluxes requires mandatory washing off of their residues after soldering. This will serve detergent or regular alkaline soap. Otherwise, the metal may be destroyed by the remaining acids.

It is important to know! Soldering irons are ideal for lower temperature lead solders. To prevent damage to jewelry the best option will use a gas burner.

Soldering silver with a gas torch

For quality repairs you should stock up:

- Insulating fireproof base (brick or asbestos board).

- Silver solder.

- Flux.

- Pickling acid solution.

- Sulfur liver.

- With a small brush.

- With wire cutters.

- With tweezers.

- Gas burner.

- Copper tongs.

- Clean cloth.

Preparation of the workplace

Before starting work, it is necessary to provide a fan to ventilate the room if necessary. In order to reduce the amount of smoke, experts recommend opening windows and turning on a ventilation device. It is important to keep strong jets away from the work area. Otherwise, the cooling process may lead to difficulties during the soldering process.

Preparing tweezers and copper tongs will allow you to cope with high temperatures. The latter do not cause corrosion and do not affect the quality of the etching solution. Tweezers are used to hold silver elements. It is allowed to make tweezers from any metal.

It is important to wear goggles and an apron to take safety precautions. The former prevent accidental splashes from getting into your eyes. Having a denim or canvas apron helps minimize the likelihood of clothing catching fire. The use of loose or hanging items is not recommended. When starting work, you should tuck up your long sleeves and tie, and hide your long hair.

When preparing a container of water used to rinse the silver at the end of the process, it is important to ensure that it is deep enough to accommodate the entire piece.

When purchasing a “seed” or acid solution, you should make sure that there is a marking for silver. It is usually sold in powder form. Before soldering, the powder is dissolved in water and heated in a saucepan or a special pickling pot. The use of a saucepan, microwave or oven intended for reuse for cooking is excluded. The etching solution may produce a metallic odor or traces of toxic materials. It is not recommended to interact steel with the etching solution. The prepared solution is stored for up to 3 weeks.

Do-it-yourself flux preparation

To carry out the process, borax is required; it is poured into a glass, filled with water and heated through a water bath. The resulting mixture is allowed to cool. A mortar is used to crush the resulting crystals.

When purchasing flux, the best solution would be general purpose, or for “surfacing” (paste, liquid). Its purpose is to clean the silver coating and transfer heat. It helps remove oxides that impede the joining process. Flux for “surfacing” allows you to join parts at high temperature conditions, with a chemical change to the surface.

Step by step instructions

High-quality soldering of silver at home is carried out with an acetylene torch with a flat tip (the pointed version is not suitable due to rapid heat dissipation, a small nozzle threatens slow heating), the whole process requires a number of steps:

- Parts intended for soldering are placed on a refractory base. It is important to provide rigid fixation of the elements relative to each other. This will be done using clamps and nichrome wire. It is important to understand that as the gaps in the welding joint area decrease, the likelihood of obtaining a beautiful and high-quality seam increases.

- After cleaning the surface from oxide films, the parts should be coated with a thin layer of flux. Fluxing or cooking is allowed required quantity gruel with water. It is applied with a brush.

- Soldering. A piece of solder should be placed in the area where welding will be done. Optimal sizes are 2x2 or 2x1 mm. The thickness of 0.5 mm is divided into parts until the desired size is obtained. The work requires the use of wire cutters or side cutters.

- The gas burner is brought to the side of the product. Carefully warm up the area where the welding joint will be made. It is important to ensure that the flow of hot gas does not affect the movement of solder and flux, and to control uniform heating. As the flux heats up, the flame will increase until the solder forms a solder joint. Solder and flux can be carefully added as needed.

- To fill cracks, you should use “light” silver solder with a small inclusion of silver, this will ensure the melting process at a lower temperature. A “medium” or “hard” solder with a high inclusion of silver will help to join the two parts together, which will ensure a stronger connection.

- Finishing requires cleaning products from flux. Excess solder is removed with sandpaper or a file. All that remains is to cover the surface with an acid solution to blacken and brighten.

Attention! Silver can be processed using tinols, which have a low level of silver in their composition.

How to connect silver parts?

The procedure includes:

Cleaning silver. The use of degreasers is recommended when working with oily or heavily contaminated silver. To clean up oxidation, the optimal solution is to place the parts in an etching solution before soldering. You can use 1000 grit sandpaper to ensure a rough surface.

Applying flux to the joint. Preparing flux requires following the instructions on the package. To apply it to finished products, you need to use a small brush. Many craftsmen apply flux only in areas where solder is applied, which will prevent it from spreading. Others place flux on large area to minimize the risk of fire damage.

The best option would be to prepare a small amount of flux in a separate container, since repeatedly immersing the brush in the main bottle will lead to contamination and negative impact to basic functions.

Arrangement of silver items for connection. When placing 2 products on the soldering brick, physical contact should be provided to ensure correct connection.

![]()

Solder placement on the connection. Using tweezers that allow you to grab a piece of solder, carefully place it at one end of the crack or break. As it melts, it will spread throughout the area where the flux is present. This eliminates the need to cover the entire length of the gap with solder.

The solder must be heated until it forms liquid composition. When igniting the burner, it is necessary to provide installation maximum temperature. The entire soldering process consists of a number of stages:

- By bringing the burner to the joint at intervals of 10 cm and rotating in a circle, heating all elements evenly.

- Slowly bring the flame to the joint area, concentrating on the solder.

- As the solder reaches its melting point, it will quickly spread onto the fluxed areas of the silver.

If one of the joined elements is thicker than the other, you should heat the thick section with back side before the solder begins to melt. Then you should quickly warm up the thin one.

In some cases, you will need tweezers to hold the products in correct position, but should be placed far from the flame. It may be necessary to retain small, thin areas of silver to achieve a given level of heat transfer.

After lowering the product into water, you should immerse it in pickling solution and let cool for 1 minute. Further cooling is done by dipping it in a bath of water.

An etching solution is considered to be an acid bath used to clean jewelry after soldering. After dipping the silver into it, you should use copper tongs and leave it for a few minutes to remove flux and oxidation. It is important to prevent contact with skin, clothing or equipment, which could cause corrosion.

After rinsing the connection area with water, all that remains is to wipe it dry with a cloth. At proper organization work, the product will be firmly connected.

Instructions

To solder small parts, use a soldering iron with a small tip or use a small gas torch, especially since refilling it requires a regular gas cartridge, and the price ratio of the cost of effort and equipment in relation to the quality of work is in the positive sector.

Thoroughly clean the surfaces to be soldered from grease, dirt and oxidizing agents, be sure to coat the joint with flux, and place a piece of solder there.

Soldering is a permanent connection of metal products using a lower melting metal. Soldering technology may differ depending on the type of metals to be joined and the conditions in which the product will operate. Thus, soldering printed circuit boards in electronics and repairing silver jewelry are performed differently.

You will need

- Soldering iron, solder, flux (colophonium)

Instructions

In electronics, when soldering parts containing silver, solder is usually used containing 60% tin and 40% lead, which melts at 180°C. Prepare the solder used for soldering electronic circuits. It is produced in the form of thin tubes filled with resin, which acts as a flux.

Clean the surfaces to be soldered by removing the oxide films that have formed over time. Only in this case does the heated solder create an internal connection with silver m.

At the soldering site, heat the part to a temperature above the melting point of the solder. Difficulty may arise when heating a large surface area with good thermal conductivity, since the power of the soldering iron may not be enough to heat it.

When soldering silver parts, protect the soldering area from exposure to oxygen. To do this, it is enough to use a suitable flux (colophonium), which forms a protective film over the soldering area. When solder melts, the flux is evenly distributed over the surface of the liquid metal.

Solder jewelry made from silver either with high-temperature solders corresponding to the metal standard, or with solders of a lower standard, but with a mandatory silver content. Solder silver products with tin only in the most extreme cases and with unconditional agreement with the customer (owner of the jewelry). This is done for the reason that repairing a silver product may become difficult in the future: if the master does not know that the product was previously soldered with tin and starts soldering it with ordinary high-temperature solder, the product may simply burn out.

Sources:

- How to solder correctly

Often during the repair process it is necessary to connect durable, for example, metal constructions. In such situations, gas burners come to the rescue. They allow you to solder almost all materials for which a melting temperature of 1000 - 1200 degrees is sufficient.

Instructions

In order to properly solder gas burner, you need to degrease those parts of the objects that need to be connected, and if necessary, remove rust with sandpaper.

Use a jet of flame to heat the area requiring soldering. To do this, constantly monitoring the size of the torch, you need to evenly move the gas burner along the seam. Please note that the flame should have a dark center, and its outer halo should be bright and with clear contours. The highest temperature will be in the core of the flame, but usually when working they use the zone outside the torch - high temperatures, as a rule, are not required.

After burner the soldering area will be heated, and its temperature will correspond to the melting temperature of the solder; bring the end of the solder rod, which is coated with flux, to the seam. He's under the influence high temperatures should melt and fill the seam.

If the solder is in powder form, then first mix it with flux and apply the mixture to the surfaces that need to be soldered. In this case, adjust the flame of the gas burner so that it is not directed towards the place with solder. Otherwise, it may oxidize prematurely and melt.

Among market consumers, silver is classified as a precious metal intended exclusively for making jewelry. However, it can also be used for technical purposes.

Physical and chemical properties of natural silver

Silver is perhaps the most common and most beloved metal by humans. It has a lot of different beneficial qualities, both chemical and physical. Silver belongs to the group of noble metals. Chemically, this element is quite inert and does not react with aggressive reagents, except for strong acids.

The thermal and electrical conductivity of silver is also high, which is widely used in industry. One of the important indicators of the qualities of this metal in the field of optics is its highest reflectivity, which led, at one time, to the appearance of mirrors. In the Middle Ages thin layer silver was applied to the glass, thereby providing a clear, undistorted image of the reflected object.

Application of silver

Silver has long been used by humans to make jewelry and various kinds of kitchen utensils, where another undeniable advantage over other metals is used - its bactericidal properties.

Depending on where silver is intended to be used, various alloys are made from it. The addition of alloys such as copper, tin, zinc, cadmium and gold gives silver a different color and slightly changes its physical and Chemical properties. Silver in its pure form is practically not used in jewelry, due to its increased ductility and low mechanical strength. The alloying components are designed to change the melting point, reduce its ability to abrasion, increase strength without changing color. Using similar processes, silver jewelry is created.

The industry uses the natural properties of pure silver. Technical silver should represent everything physical properties, allowing its use in the radio and electrical industries, the main one of which is its unique electrical conductivity.

Technical silver – areas of application

The term “technical silver” is not entirely correct, since it hints at the imperfect purity of the metal. However, unlike industrial diamonds, which are essentially highly flawed, industrial silver, on the contrary, is very pure - 99.9%. The remaining 0.1% is due to impurities, and the composition of this alloy is strictly defined.

Wires and contacts are coated with technical silver, contact groups are cast from it and individual elements electrical structures. In its pure form, technical silver is also present in radio components of devices produced in the Soviet Union. Until the 90s of the last century, pure technical silver was used to make photographic film materials.

When is it necessary to improve some mechanical properties(for example, impact strength in contacts of large starters), cadmium is added to the alloy. The obtained result does not have a significant effect on the electrical conductivity.

The so-called secondary technical silver is obtained from technical silver-containing alloys. Recycling of silver-containing scrap is both economically important and solves issues related to the disposal of hazardous impurities when processing contact silver-containing masses coming from chemical plants.

remember that when preparing solder yourself silver products It is best to solder by mixing silver with brass in a ratio of 3 to 1.

Sources:

- how to make your own silver spoon