Cement mortar for laying tiles. Solutions and mixtures for tiles - types, compositions, mixing rules and the best manufacturers. How to prepare glue for work

Every person who decides to lay tiles with their own hands must first think about how and with what help to fix it on the surface. the main role solution for ceramic tiles– installation of a tiled covering by fixing it to the floor or wall. It’s not at all difficult to prepare it yourself, at home.

The first thing you need to do is decide on the composition. There are two types of mortar for ceramic tiles:

- cement- glue mixture, made by hand. It is a universal and most reliable material;

- ready-made dry mixtures sold in stores and markets. They are intended only for smooth, plastered surfaces made of concrete, brick, and wood.

The first option is the most popular. The composition of the cement-adhesive mixture does not depend on where it will be glued tile covering, on the floor or on the walls. To make it, it is advisable to use purified, coarse sand and cement. The higher the grade of cement, the better the quality of the solution, but in any case it should not be lower than 300. If you use cement of grade 300-400, then its ratio with sand will be 1:5, and if you take cement of grade 500-600 - then 1:6.

In order to achieve good adhesion of the surface to the solution, you can dilute it with PVA glue.

The sand used, if it is damp, must be dried, because wet will not pass through a fine sieve when sifting.

When purchasing cement, be sure to check the release date. If the expiration date has expired or is close to it, then it has probably lost half of its properties. If the purchased cement does not have packaging, then its suitability can be determined as follows: you need to take a handful of it and squeeze it, while the fresh one will come out between your fingers, and the expired one will clump into a lump.

Cement mortar

To make cement-adhesive mortar for ceramic tiles, the technology used is as follows:

- First of all, you need to sift the sand. If this is not done, then various pebbles, fragments of shells, pieces of clay that may be in it will fall into the solution and the tiles laid on it may subsequently crack;

- The sifted sand is mixed with cement in the above proportion, adding water until it is thick enough to resemble dough. After this, the solution is ready for use.

- To ensure good adhesion, you can pour PVA glue into it - 1/2 liter of glue is taken for 10 liters of solution.

An excellent replacement for the cement-adhesive mixture is a ready-made dry mixture (tile adhesive) purchased in a store. It consists of cement, sand and a huge number of various chemical additives that give it properties appropriate for its intended purpose. This mixture is subsequently used to make a mortar for ceramic tiles. The price usually depends on the manufacturer and the quality of its components.

Dry mixture solution

Working with such mixtures requires strict adherence to the instructions. The adhesive properties of ready-made suspensions are better, and they are also diluted with special antifungal additives. But all this is true only if the solution is made correctly:

- must be protected during operation Airways using a respirator or gauze bandage;

- pour three liters of water at 22-24 C into a clean ten-liter bucket;

- Gradually pour the dry mixture into the water, stirring continuously. The finished volume should be approximately 2/3 of the bucket;

- Stir the mixture thoroughly so that no lumps remain. This can be done using a special whisk;

- to enhance adhesion, dilute the solution with PVA glue at the rate of 1/2 liter per 10 liters of composition;

- the finished solution must be allowed to stand for ten minutes and mixed again.

Types of ready-made dry mixes (tile adhesive)

- Universal mixture. It is most popular and is used for fixing small tiles. It is usually used to decorate rooms with ordinary tiles.

- Strengthened mixture. Its main purpose is to fix large tiles on the floor and walls. Characteristic feature This type of mixture is to ensure good adhesion to the surface and high resistance to various types of loads.

- Pool mix. With its help, pools and baths are decorated with mosaic tiles. This mixture is moisture resistant and includes components that prevent the appearance of mold.

- Frost-resistant mixture. Designed for outdoor use. With its help, the plinths of buildings, stairs, terraces, etc. are covered with tiles. This mixture is resistant to repeated freezing and subsequent thawing.

These are the main types of ready-made dry mixtures from which mortar for ceramic tiles is made. Photos of them can be viewed on the Internet on the websites of enterprises selling building materials.

How to choose good quality ready-made dry mix

There are several criteria that you need to rely on when choosing a ready-made mixture:

- When purchasing a ready-made mixture, you should always check the expiration date and compliance with storage conditions. If they are violated, this material may partially or completely deteriorate;

- It is better not to purchase a mixture that was produced more than six months ago, because... it tends to cake and may subsequently become petrified;

- where and by whom the mixture was released also matters. There is a myth that says that when purchasing expensive materials, people overpay for the brand that is depicted on the packaging, but this judgment is far from the truth. Manufacturers who have been on the market for a long time, in order to stay afloat in conditions of fierce competition, constantly research the properties and compositions of mixtures, improving their products.

- When choosing the type of this material, you should not buy the same one for the walls and floor because... they will be subject to different loads. It’s better not to save money and purchase a reinforced mixture for the walls.

With the help of this guide, any beginner in renovation and construction will be able to independently prepare a solution for ceramic tiles. Videos from more clear instructions see below.

Advice: despite the fact that all mixtures have already been selected optimal composition ingredients, there are several additional additives that will make the glue even stronger. Manufacturers do not add them because it is not cost-effective and significantly complicates the production process. Such additional substances include PVA glue (added to the diluted mixture) and cement (above grade 50).

There are quite a lot of different companies represented on the dry mix market, but not all of them offer decent products. Among the time-tested and customer reviews are:

- Ceresit,

- Optirok (Vetonit),

- Atlas

- Sopro,

- Bolars,

- Eunice.

The most famous of all manufacturers is without a doubt the products of Ceresit. This brand is part of the Henkel concern, which also produces products under the Thomsit, Metylan and Moment brands. The main facilities are located in Ukraine, but the products fully comply with the requirements and technical standards. The assortment offers quite a lot of different compositions, which differ from each other in the composition and method of using the tiles. Eat frost-resistant mixtures for outdoor use and various compositions for porcelain stoneware, thin tiles and other types of tiles.

The Finnish corporation Optirok offers the Vetonit product range to domestic consumers. Taking into account the harsh Finnish weather conditions, the adhesive mixtures are made with an additional margin of strength, so Vetonit adhesives suitable for work in all regions of Russia.

Polish Atlas is also of quite high quality, but costs less than its analogues. The company specializes specifically in adhesive mixtures, so it offers quite a lot of compositions designed for specific loads. This allows you to optimize the tile installation process to maximize its service life.

Sopro is German company, which has been repeatedly awarded at international construction competitions. Of course, the quality of its products is the highest level, in connection with this, domestic distributors significantly inflate the cost of goods. It makes sense to choose this company if a large amount of work is required and a wholesale purchase is possible. Then the price will be acceptable.

Of the domestic companies, Bolars and Yunis are worthy of attention. Both companies have own factories in Russia. The products comply with GOST. Since there are no costs for customs clearance and delivery, the products of these manufacturers are cheaper. But little experience in this industry allows us to recommend companies exclusively for interior work for finishing tiled walls. Also, it should be added that the Moscow company Yunis does not yet have a wide network of distributors, therefore it is available only to residents of the Moscow region.

Properly prepared tile mortar has great importance For high-quality cladding walls or floors indoors and outdoors. The strength of fixation of the tile depends on it, so the choice of adhesive mixture must be approached competently. Construction market offers dozens of types of tile adhesives. Let's consider their features and selection rules.

There are two types of mortar for ceramic tiles:

- Made from cement, sand and water. This mixture is universal. Its disadvantage is that the components are taken “by eye”. The amount of sand depends on the brand of cement. An incorrect ratio of components affects the quality of the cladding. The cement-based composition has good adhesion and is used for interior and exterior work. Laying tiles on cement-sand mortar can be done on any surface.

- Tile adhesive. It is purchased in the retail chain in the form of a special dry concentrate. The binder is cement, sometimes gypsum. Powder concentrate contains special additives, which impart different properties. All ingredients are in an optimal ratio, which improves the properties of the solution (ductility, adhesion, water resistance, heat resistance). It can be used not only for fixing tiles, but also for gypsum tiles, as well as glass, porcelain stoneware and facing stone. The preparation method is simple and indicated on the package.

Among the manufacturers of ready-mixes, the leaders are the German company Ceresit and the Finnish Optirok. The quality of their products is time-tested.

Dry adhesive mixtures

Solution for tiles, prepared from dry adhesive mixtures, has high adhesive properties. Cement-based glue is considered the best. The following components are used as additives to give the adhesive mass the desired properties:

- Antiseptic additives that prevent the appearance of mold.

- Hydrophobizers that create water repellent properties.

- Frost-resistant chemical substances.

- Catalysts to speed up or slow down the setting of a solution.

- Plasticizers that give the solution the desired plasticity.

Powder concentrate comes in two types: one-component (based on one binder) or two-component (with mineral and polymer binders). The latter type of mixture requires precise dosing when preparing the solution, which is difficult to do without the appropriate experience.

The quality of dry mixtures depends on storage conditions: they do not tolerate dampness or low temperatures. At long-term storage cake and can petrify, so they have a limited shelf life of six months.

Laying tiles on a dry adhesive mixture requires strict adherence to the preparation instructions, as well as careful preparation work surface. According to the laying technology, a solution of powdered tile adhesive is applied thin layer- 6-10 mm.

Dry mixtures are environmentally friendly, easy to use, reliably stick tiles, but have high cost compared to cement-sand mortar prepared independently.

Ready-made viscous mastics

The most commonly used solution for laying tiles is cement-based or dry adhesive mixtures. As an alternative, you can use adhesive mastic, sold in finished form.

The composition of adhesive mastic mixtures includes petroleum bitumen, tar binders or combinations thereof. Various additives are used as additional components: peat chips, coal tar pitch, chalk, asbestos, cement, wood flour, antiseptics. To improve adhesion, polymer binders are introduced into some types of mastic. If desired, the mastic composition can be given the desired color by adding a coloring pigment.

There are 2 types of mastics: used hot or cold. The first ones are preheated to 130-180 °C. Usage cold mastic allows for cladding at temperatures not lower than +5 °C. With more low temperatures the mixture is heated to 60 °C.

Even a beginner can lay tiles using mastic compounds. The mass is applied in a thin layer (2-3 mm), so the working surface must be flat. Otherwise, you will have to apply an additional layer in places where there are chips. This will lead to excess consumption of the mixture and deterioration of the strength of the connection.

For exterior work, cladding of fireplaces, stoves, universal heat-moisture resistant or heat-resistant mastic is used.

Difference in mixtures

The peculiarities of the solutions are determined by the modifying additives. There are the following types of adhesive mixtures for tiles:

- Universal. Used to fix tiles Not large sizes in room.

- Reinforced. Fixes tiles of all types and sizes. Suitable for laying fragile tiles.

- For swimming pools, baths. Has good hydrophobic properties, has impurities to prevent mold.

- Frost-resistant. Used for outdoor work. Withstands repeated changes in low temperatures.

For each type of surface to be coated, a composition with the necessary characteristics.

For walls and floors

Mixtures for laying ceramic tiles on floors and walls are not much different. But for floor coverings, it is desirable that the composition has high elasticity and is thicker. Plasticity also plays an important role: the risk of cracking of the tiles is reduced. If the subfloor is heated, heat-resistant tile adhesive is used.

For external and internal work

To obtain a good result, a solution for external facing works must be resistant to atmospheric influences. Therefore, components are added to the powder concentrate that increase moisture resistance, frost resistance, and elasticity (which resists temperature changes).

Traditional mortar made from sand and cement for tiles with your own hands is used for both interior and exterior work, but is not suitable for clinker tiles.

For small and large elements

To prevent large tiles (more than 300x600 mm) from sliding down the wall, it is recommended to use a reinforced adhesive solution with latex components and granular material for its installation. quartz sand. For mosaic tiles are used polymer compositions and special white tile adhesive.

Laying tiles on cement mortar is done according to the rule: the smaller the size, the more liquid the consistency of the adhesive mass.

For dry and wet conditions

In rooms with high humidity, a waterproof cement-based adhesive mixture is used: it has the highest adhesive ability. High room humidity promotes the growth of fungi and mold, so the powder concentrate must be moisture resistant and contain antifungal additives.

The solution for dry rooms is marked “for interior use.” It is chosen depending on the characteristics of the tile and the facing surface.

Cement mortar for baths, bathrooms and other rooms with high humidity is prepared from sand and cement.

For normal and elevated temperatures

Indoors, where there is no high temperatures, cement-sand and universal adhesives are used for cladding walls and floors. But they are not suitable for finishing heated surfaces. The tiles on the fireplace or stove are laid on a refractory compound.

How to delete

You can wipe off fresh cement mortar from the tiles with a dry rag. Old cement-adhesive mortar can be removed by wetting the surface with any of the following:

- special remover (sold in building materials stores);

- toilet bowl cleaning liquid;

- hydrochloric acid(5% solution).

After 5 minutes, the softened solution is removed with a sponge moistened with water.

Mechanically The remaining solution is removed as follows:

- Moisten with water, sprinkle generously with salt, then remove with a stiff bristle brush.

- Moisten the remaining adhesive mixture with water and remove with a spatula, being careful.

- Use a drill with a wire attachment.

Fresh mastic residues from the lined surface are removed with a damp cloth. Dried residues are moistened with warm water for several minutes or hours before removal. A cleanser with a citrus extract speeds up the process. Acid cleaners can be used.

In order to securely fix the tiles to the wall, you should use cement mortar or a solution based on a dry adhesive mixture. These compositions are easy to make yourself at home. How to do it? Read our instructions.

Making cement mortar

The easiest way to lay tiles is to use a cement mixture. Cement mixture is a cement mortar (the higher its grade, the better quality mortar) and sand. Pour them with water and mix thoroughly until a homogeneous creamy mass is obtained. The ratio of cement and sand in the mortar for facing work is 1:4.

Preparing the dry adhesive mixture

In order to create an adhesive composition based on a dry mixture purchased in a store:

1. Put on a respirator or gauze bandage to protect your respiratory tract.

2. Pour 3 liters of water room temperature into a clean 10 liter bucket.

3. Gradually add the prepared adhesive mixture to the container, constantly stirring the composition (the resulting mass should ultimately occupy about 2/3 of the bucket).

4. Finish mixing the composition, carefully destroying all lumps. Use a trowel or whisk clamped in a hand-held power drill.

5. To enhance the adhesion capabilities of the mixture, add PVA glue to the solution (0.5 liters per 10 liters of the finished composition).

6. Wait 5-10 minutes, allowing the contents of the bucket to settle, and mix thoroughly again.

Preparing tile adhesive (video):

Before starting any repair work It’s worth deciding on the choice of materials, which will greatly simplify the process of preparing and purchasing all components. Laying tiles requires determining the type of mixture that will ensure high-quality fastening of the ceramics.

To do this, it is important to know what mixtures are available for ceramic tiles, then the result of the repair will be pleasing long years operation.

Types of existing mixtures

Manufacturers offer two types of mixtures on the market:

- ready to use;

- dry mixes.

1. They differ not only in composition, but also in quality. Ready-made mixtures are based on latex or petroleum products; they are easy to use due to reduced labor intensity. Latex-based mastics contain purified water; it evaporates as the glue hardens. And as an additive to mastics from petroleum products there is a solvent, which, like water, evaporates when the solution dries completely. It is offered to the consumer in buckets of various capacities.

2. Dry mixtures for laying ceramic tiles are considered more reliable; the cement base ensures reliable fastening of the coating for a long service life. Due to its high compressive strength, the adhesive mixture can withstand heavy loads, which is ideal for working with surfaces inside and outside the building.

Comparative analysis of the proposed compositions

Compared to ready-made mastics, the second option has many advantages, since it differs not only in cost, but also in characteristics.

- The price of dry mixes for ceramic tiles is lower than for adhesive solutions in buckets. When comparing the cost of the same volume of ready-made and prepared glue, the difference will be significant.

- Products in bags are designed to work with various surfaces– concrete, brick and plastered with cement-sand or cement-lime mortar.

- Dry glue is ideal for simultaneous leveling of surfaces, so work is possible with walls of any curvature. And before applying mastic, the surface requires careful leveling and processing.

- Dismantling prepared cement-based mortars is much easier to dismantle. A hammer drill will help with this, and the mastics will be removed from the walls along with part of the base. Although people do not always think about the future dismantling of the tiles when laying.

Selecting material according to purpose

The adhesive for use is selected depending on its purpose; the technology for producing a mixture for ceramic tiles involves adding components for use in interior and exterior work. The second type usually has a more expensive cost due to additional water-repellent components.

Defining properties of a quality product

A high-quality adhesive composition has the following properties:

- moderate plasticity; for wall cladding, the solution should not spread. Because the mixture is laid in a layer of a certain thickness, which is not possible if it spreads. Plasticity should not change when mixing a thin or thick solution;

- for floor covering, the mixture should spread well, thereby filling all the voids. The absence of a densely laid mixture under the tiles is fraught with violation of the integrity of the entire coating, as well as damage to individual tiles even under light loads;

- have good adhesion, that is, have sufficient adhesion force to the material. This is relevant for working with ceramics, especially in our time, when one element has large dimensions and, accordingly, weight;

- normal drying speed, during operation it should be possible to adjust the location of the tiles. It has been proven that when the solution dries slowly, the bond strength increases significantly, and the resulting surface then has excellent performance properties.

Before choosing mixtures for ceramic tiles, you need to familiarize yourself with the characteristics of the proposed options. A store consultant or a familiar specialist who regularly deals with this type of work will help with this.

Examples of manufacturers on the market

Many manufacturers produce products under different trademarks, mixtures from the following companies are popular on the market:

- Ceresite;

- Hercules;

- Brigadier;

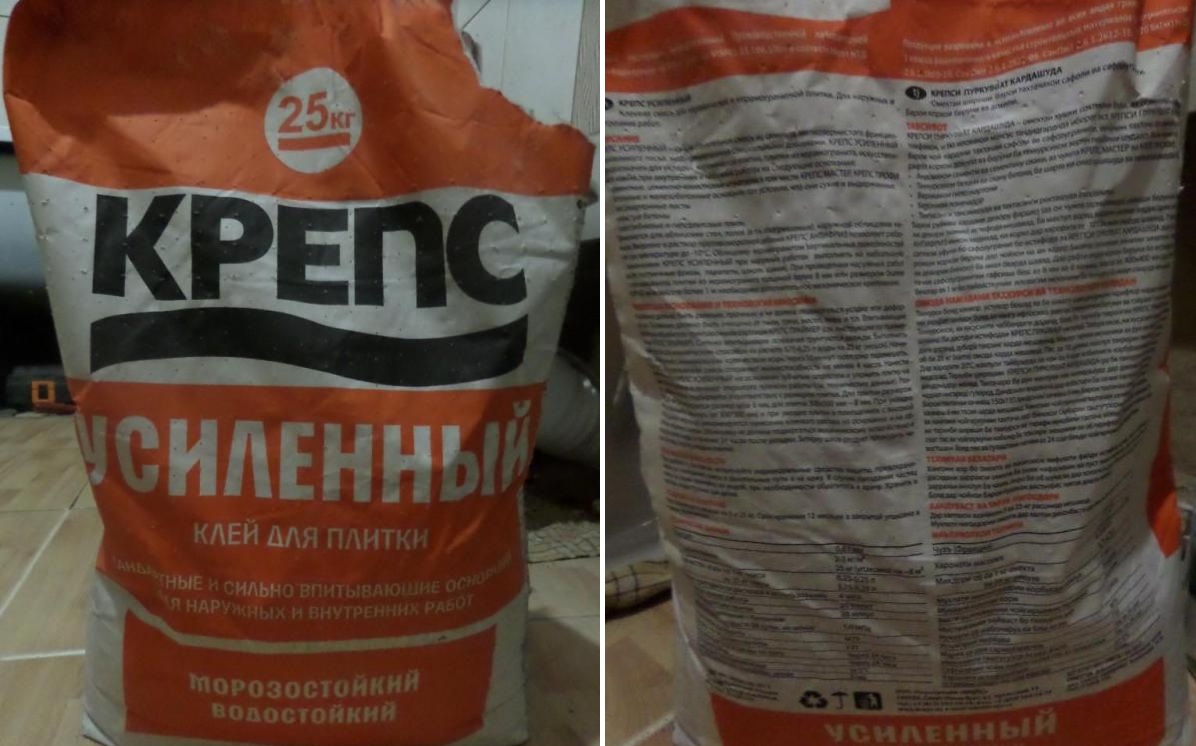

- Craps;

- Bolars.

1. The Ceresit brand offers a variety of products for construction, mainly mixtures for finishing works. This company is known in many countries; the quality of its products allows it to carry out a wide range of work on optimal cost. The universal mixture for working with tiles is Ceresit SM 115. It is suitable for laying marble and glass tiles, mosaics indoors and outdoors, ideally attaches the material to any surface.

2. The Hercules company produces mixtures for tiling walls and floors, suitable for use in rooms with high humidity and for outdoor use. The manufacturer guarantees the quality of the adhesive composition; the shelf life of the prepared solution is 3.5-4 hours. After the mixture has completely hardened, it has high moisture and frost resistance.

3. Brigadier glue has excellent properties and is well suited for working in different conditions. Distinctive property is its efficiency; you can work with the prepared mixture for 4 hours. But after applying a layer of glue to the surface, you need to lay the tiles in 10 minutes.

4. Kreps is a little cheaper than Ceresit, but the quality is similar. They cope with the task perfectly, but the grinding coarseness of the mixture is slightly larger than that of analogues. Due to this, the solution is less mobile, but this does not significantly affect the work.

5. Bolars mixtures have mixed reviews from both professional craftsmen and ordinary buyers. The mixtures are produced cheaply, but the prepared solution slides along the surface, so it is not always possible to lay tiles well. For examples, you can see photos of mixtures for ceramic tiles.

Before you start laying tiles, it is important to prepare the mortar correctly; to do this, you should read the instructions from the manufacturer in advance and adhere to the process technology. And with experience, the master always succeeds positive result labor, although everyone gets used to working with materials from certain manufacturers.

Tile adhesive is available in a wide range, and it is not at all easy for a novice master to make a choice. But a properly selected composition is a guarantee that the tile will not move under load, and the coating will last for many years.

What kind of glue would be better suited for ceramic tiles, and which one for stone tiles? What is more profitable - ready-made mixture or dry? Is it worth buying expensive glue and how can you save money? These questions concern everyone who has decided to do the cladding on their own for the first time. Let's consider how to choose glue for floor tiles to obtain high-quality and durable coating.

Depending on the form of release, tile adhesive is divided into three groups - dry mixtures, two-component mixtures and paste-like compositions, ready for use.

Dry mixes

This group includes cement-based powder mixtures, which are mixed with water immediately before application. The glue is made from gray and white cement, and in addition to the binder, it contains various additives to improve the qualities of the material. For floor tiles, gray cement adhesive is mainly used (white is intended for transparent tiles and mosaics, so it is more suitable for walls).

Cement adhesive solutions are divided into thick-layer and thin-layer, depending on the composition of the components and the granularity of the filler. The first type allows you to lay tiles on the base with a height difference of up to 30 mm, thereby simplifying the preparation of the floor. But at the same time thick layer gives strong shrinkage and requires more time to dry, and also increases material consumption.

Highly elastic white tile adhesive, thick layer: 3-10 mm

Thin-layer mixtures can be applied to floors whose differences do not exceed 10 mm. They are much less susceptible to shrinkage, dry faster, and are characterized by low consumption.

Two-component mixtures

These compositions have an epoxy-polyurethane base and differ more high performance, compared to cement adhesives. Prepare the solution immediately before application by mixing the base composition with the hardener. Such adhesives are characterized by the absence of shrinkage, elasticity, low specific gravity, and water resistance. They are resistant to vibrations and deformations, and are better suited than others for floors subject to intense loads.

The solution takes about 20 minutes to set, and complete drying occurs in a few hours, which can significantly reduce repair time. The quality of gluing directly depends on compliance correct proportions when mixing components.

Ready mixes

This group includes water-dispersion compositions made on acrylic, latex and polyvinyl acetate bases. Glue solution It is mixed in production and sold in hermetically sealed containers. Before applying the glue, you just need to mix it. Ready-made solutions have a thick consistency, do not spread, and perfectly hold tiles of any weight and size.

The advantage of such compositions is that they save time during installation, since there is no need to be distracted by mixing the solution. In addition, dispersion adhesive has excellent adhesive properties, strength, and does not have a pungent odor or toxic impurities. After curing, the adhesive layer is sufficiently resistant to vibration, static and dynamic loads, which ensures a long service life of the cladding.

According to its characteristics adhesive compositions are also divided into several types:

- universal- the most popular type used for internal and external cladding. It is affordable, easy to apply, and ensures reliable adhesion of the tile to the base. This adhesive is intended for standard tiles ranging in size from 10x10 cm to 30x30 cm;

- reinforced– contains special additives to increase the adhesion and strength of the adhesive layer. It is used when laying large tiles, porcelain stoneware and natural stone. This adhesive, after curing, is immune to static and dynamic loads, therefore best suited for areas with heavy traffic;

- moisture resistant– contains special hydrophobic additives that provide resistance to moisture vapors and direct influence water. This glue is used for cladding bathrooms, showers, kitchens, and swimming pools. Many manufacturers add antifungal additives to the glue, so that mold does not grow in the tile joints.

Special compositions are also produced, for example, white cement glue for transparent cladding, glue for exterior finishing, adhesive for underfloor heating.

Prices for tile adhesive "Ceresit"

ceresit tile adhesive

Basic requirements for tile adhesive

Regardless of the composition and form of release, tile adhesive must comply with accepted standards and meet the basic requirements:

- it must have high ductility and fit easily onto the work surface;

- have good adhesive properties and reliably fasten the cladding to the base;

- the glue should not shrink significantly (ideally, this indicator should be zero);

- the viability of the solution and the adjustment time must be long enough so that the master has the opportunity to properly fit all the elements and eliminate masonry defects.

These conditions apply directly to the solution, but there are also requirements related to the hardened adhesive layer:

- resistance to deformation, that is, the strength of the adhesive in compression and shear;

- resistance to temperature changes;

- resistance to high humidity.

The glue packaging indicates the main characteristics of the composition: its strength, specific gravity, pot life and complete drying time, degree of resistance to various types influences. So before purchasing, you should carefully read the glue characteristics - this will allow you to choose best option mixtures for specific conditions.

How to calculate consumption

The consumption of dry mixture depends on several factors:

- thickness of the adhesive layer– the thicker the glue is applied, the more it will be needed;

- floor quality– on a flat, weakly absorbent surface, much less glue is required than on porous substrates with differences of up to 10-15 mm;

- consistency and chemical composition glue– the thicker the solution, the more it is consumed. Synthetic-based mixtures have better adhesive properties and hold tiles well even when applied in thin layers, so their consumption is lower than that of conventional cement adhesive;

- type of tile– enough for small tiles minimum thickness adhesive layer; for large-format applications, the application thickness increases to 10-12 mm. The same applies to the density of the material - tiles with a porous structure require more glue than dense porcelain stoneware.

The professionalism of the master also plays a role, because it is very difficult for a beginner to correctly lay tiles on a thin layer the first time, a lot of mortar is spent on correcting mistakes.

The consumption of the mixture per meter of area is indicated on the packaging (minimum and maximum values), and all that remains to be done is to multiply it by the total floor area. For calculations, it is better to take the maximum value, and the resulting volume should be increased by another 10-15%.

Best Brands of Tile Adhesive

In order not to make a mistake in choosing, it is worth purchasing products popular manufacturers, which fully meets the specified requirements, in contrast to cheap handicraft mixtures. The leaders in this area are the companies Ceresit and Knauf: entire lines are produced under the same brands tile adhesives and repair compounds in a wide price range. Here you can easily choose adhesives for all types of tiles, natural stone, porcelain stoneware, waterproof and frost-resistant compounds, and mixtures for laying tiles on heated floors.

The adhesives “Osnovit”, “Yunis”, and “Starateli” are in high demand. Even the simplest cement compositions are distinguished by their adhesive strength and durability, are easy to apply, and have a long setting period. Among the reinforced types of glue, “Plitonit” stands out due to its characteristics - mixtures of this brand are excellent for floors in high-traffic areas.

| Name of glue | Main characteristics |

|---|---|

| The adhesive has enhanced adhesive strength, resistance to moisture and sudden temperature changes, and is suitable for lining heated floors. Used for laying tiles from 30x30 cm to 60x60 cm. Can even out height differences on the working surface up to 15 mm. Average consumption is 1.4 kg/m2, pot life of the mixture is 180 minutes |

| A universal composition that is great for beginners. The mixture is very plastic, easily distributed over the surface, and firmly adheres to the base. The viability of the solution lasts 120 minutes, the adjustment time is about 20 minutes. Apply glue in a layer from 2 to 10 mm, consumption is 2.7 kg/m2 |

| Waterproof composition for ceramic tiles and porcelain stoneware up to 60x60 cm in size. Suitable for any surface, characterized by plasticity and ease of application. Maximum permissible thickness layer – 10 mm. The solution remains viable for 4 hours, dry mixture consumption is from 1.7 to 4.3 kg/m2 |

| The composition is suitable for tiles and porcelain stoneware of any format, can be used in unheated rooms, at normal and high humidity. It is applied in a layer up to 15 mm thick, consumption is from 3 to 5 kg/m2. The solution remains viable for 240 minutes, adjustment time is about 10 minutes |

| Ready mix with extended adjustment time. Suitable for ceramic tiles of any format, can be used in bathrooms, kitchens, bathrooms. Consumption per m2 ranges from 1.5 to 4 kg. |

| Ready-made heat-resistant adhesive mixture. It has increased moisture resistance and is suitable for all types of floor tiles, natural stone, and agglomerates. Maximum thickness application – 4 mm, complete drying time – up to 120 hours. Consumption ranges from 0.5 to 1 kg per m2 |

You should immediately take into account that it is advisable to use expensive compounds under specific operating conditions for which these adhesives are intended. For example, on substrates subject to vibration, shrinkage, and large dynamic loads, it is worth using two-component adhesives, durable and elastic. When tiling the floor in a bathroom, washing room, basin bowls are required waterproof mixtures, and in unheated rooms - frost-resistant.

If you are tiling a bathroom, you should use an adhesive with increased moisture resistance.

It is also justified to use special adhesives when you need to lay tiles not on a concrete floor or screed, but on wood covering or a stone floor.

For ordinary apartment it's best to use simple ones cement adhesives: they perfectly withstand household loads, small changes in humidity and temperature, and are suitable for tiles of any type and format. You can take cement composition with improved characteristics - thanks to various additives, such mixtures are more waterproof and elastic, and the price is not much more expensive.

Now regarding ready-made and dry adhesives. Ready-made mixtures are not intended for storage, so they need to be worked out at a time. They are applied in a thin layer, which means the surface must be carefully leveled in advance. WITH practical side, it is advisable to choose such compositions for small rooms where glue consumption will be low. The advantages of ready-made mixtures include quick drying, excellent adhesion when applied in thin layers and saving time on cladding.

Dry glue is cheaper and can be used as needed, the main thing is to close the bag tightly so that the mixture does not get damp.

Using cement adhesive, you can level out small differences in the floor and reduce the cost of leveling screed. The main problem for beginners is preparing the correct consistency of glue, because if you just add a little less or overfill the water, the glue will no longer be so strong. But if you strictly follow the instructions, where all the necessary proportions are precisely indicated, then achieving the desired result is not at all difficult. So, from a practical point of view, it is still more profitable to choose dry mixtures for floor tiles.

How to prepare glue for work

Not only the quality of adhesion of the tiles to the base, but also the ease of working with the mortar depends on the correct mixing. Too thick, like too liquid composition It is difficult to distribute evenly; it takes more time to finish. To dilute the dry mixture, you will need:

- two containers - empty and with clean water room temperature;

- a bag of dry tile adhesive;

- drill with mixer attachment.

Step 1. Part of the water, approximately 2/3 of the norm, is poured into an empty container.

Step 2. Pour dry glue from a bag into the water, measuring out the required amount.

Advice. The dry composition is always poured into water, and not vice versa. This promotes better mixing, there are no dry lumps left at the bottom, and less dust is generated.

Step 3. Insert the mixer into the container and mix at low speed for about a minute.

Step 4. If the mixture turns out to be too thick, take it in lumps, add water in small portions and stir each time until the solution reaches the required consistency.

Step 5. Leave the glue to swell for 10 minutes and stir one last time. The solution must be absolutely homogeneous, plastic, and moderately thick.

How to glue tiles to the floor

The tiling process requires diligence and accuracy, because the slightest defects are clearly visible on the tiled surface, especially if the tile correct form and plain. Let's look at how to glue tiles to the floor to get a high-quality coating.

Step 1. The floor surface must be thoroughly cleaned—scrape off dirt, paint stains, putty, and vacuum.

Step 3. From the center of the doorway draw a straight line to the opposite wall.

Step 4. The first row of tiles is laid out along a line on a dry floor, observing the width of the joints.

Step 5. By outer edge On the last tile, a second marking line is drawn - perpendicular to the first. Laying will be carried out from the point of intersection of the lines.

Step 6. Prepare the adhesive solution according to the manufacturer's instructions.

Step 7 Apply glue with a trowel along the marking lines slightly wider than the width of the tile.

Step 8 The adhesive layer is leveled and then passed over it with a notched spatula, forming a relief.

Advice. If the tile is large-format, on it back side a thin adhesive layer is also applied. For standard tiles, an additional layer of adhesive is not needed.

Step 9 Take the first tile and lay it on the glue so that its sides exactly coincide with the marking lines. Lay on top wooden block and tap it with a rubber hammer so that the tiles lie evenly.

Step 10 Insert crosses for the seams on the sides and continue laying the first row, controlling the placement of the tiles using the rule and level.

Step 11 Having completed the first row, proceed to the next. During the work, it is very important to maintain the width of the seams and do not forget to control the plane.

Step 12 When cutting tiles, you must mark the cut line with a pencil, having first measured the required distance. It is most convenient to cut the material with a tile cutter, manual or electric.

Cutting with a manual tile cutter

Advice. If a shaped cutout is needed, first mark it with a pencil on the surface of the tile, and then divide the part that needs to be cut into squares. After making cuts along the lines, remove excess fragments, and break off uneven edges using pliers.

The remaining pieces are broken off with pliers or wire cutters.

Step 13 Along the perimeter of the room they fix ceramic baseboard, placing crosses underneath for seams.

Step 14 A day after the lining, the joints are grouted. The mixture is applied across the joints, carefully filling all the irregularities. As soon as the grout has set, the floor should be wiped with a damp, clean sponge. The remaining residue after drying is removed with a dry cloth.

Cleaning tiles with a cloth