Control gear for sodium lamps. How to connect a sodium lamp.

In 2012, Novazavod LLC began serial production IZU for DnaT lamps and DID (MGL). The line of manufactured IZUs covers all types of lamps, both in power: from 35W to 2000 W, and in base type: E27 and E40. A special series IZU-Agro is also produced, designed to run DnaZ 400/600 W lamps, widely used in greenhouses and those having the specificity of “tight ignition”.

Compliance with GOST R IEC 926-98, GOST R IEC 927-98

Advantages of IZU "Novazavod" compared to manufactured analogues:

- use of components from the world's leading manufacturer NXP (Philips);

- automatic installation of components on the board using MYDATA MY-9 equipment (Sweden);

- the use of inductive components, which are the “heart of the IZU” from EPCOS (TDK) with a closed loop, allows you to calibrate the IZU power with an accuracy of up to 5% for each type of lamp;

- The pulse amplitude and its shape are monitored on an HP Hewlett-Packard oscilloscope.

All of the above, as well as practically none “ manual labor» allows the production of IZU at the level of the world's leading analogues with a failure rate of 0.5% and 18 months warranty.

The ideal pulse shape, adjusted for each type of lamp, allows for a “soft start” mode, which increases lamp life up to 2 times.

Example notation IZU for DNAT when ordering: IZU-100/400 - Pulse Ignition Device for HPS lamps with power from 100 to 400 W.

Price for products at 08/30/2017. Certificate of Conformity No. ROSS RU. АВ86.Н01670

Prices apply for long-term deliveries or for one-time orders of 200 pcs.

|

IZU type |

Lamp type |

price, rub. VAT included |

Size, L*W*H/weight, g. |

|

IZU 35/70 |

DNAT/DRI 35-70 W |

120 |

55*40*35/ 55 |

|

IZU 100/400 |

DNAT/DRI 100/400 W. |

120 |

55*40*35/ 60 |

|

IZU 100/1000 |

DNAT/DRI 100/1000 W |

120 |

55*40*35/ 60 |

|

IZU 1000/2000 |

DNAT/DRI 1000/2000 W |

160 |

55*40*35/ 75 |

|

IZU Agro400/600 |

DnaZ 400/600 W |

180 |

55*40*35/ 90 |

Pulse ignition devices - IZU are designed for ignition gas discharge lamps high pressure sodium type DnaT and metal halide type DRI (MGL) when switched on together with ballast-inductive ballast. There are IZUs for working with a voltage of 220V and a voltage of 380V (usually for lamps with a power of over 1000 W). Power of DnaT, DRI lamps from 35 to 2000 W. The most common in street lighting: IZU 250 for DnaT lamps, DRI: 100W-400 W., in greenhouse lighting: IZU 600 W - IZU 1000 Tue Typically used in JSP lamps, sodium lamp floodlights

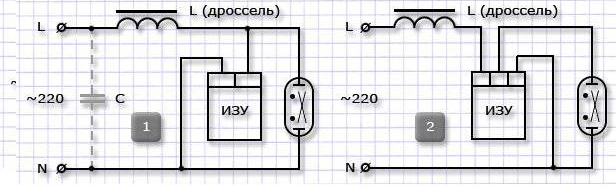

Typically, IZU is divided into three types:

With two terminals, also called parallel type, the simplest circuit design,

manufactured since the early 80s. - simultaneously with the advent of HPS lamps, IZU connection diagram- Fig. 1. But despite the simplicity and reliability of such IZUs, they have a number of problems that cannot be solved in these schemes:

- failure of the IZU in the absence of a lamp or if a burnt-out lamp is installed.

Output from a standing ballast, since pulses from the IZU up to 5 kV are supplied continuously and the windings

chokes burn out sooner or later. There is a solution for protecting ballasts - installation

Ballast with thermal protection, but due to its high cost and lack of Russian GOSTs

for its mandatory installation, it is installed extremely rarely. Buy IZU the outdated type is simpler, but this will further affect the costs of maintaining the lamp as a whole.

-The distance from the IZU to the ballast is limited to 1-2 meters.

With three terminals or “serial type”. Connection diagram IZU devices sequential type is shown in Fig. 2. Advantages:

operability of IZU and ballasts in the absence or combustion of the lamp.

- IZU distance is unlimited.

A huge disadvantage: towards the end of the lamp’s life, the rectifying effect begins to appear, which leads to abnormal operation of the ballast, the IZU also works continuously, trying to light the lamp, which leads to the breakdown of the entire system IZU-PRA

The most modern IZUs of both types have a digital timer that turns off the IZU after a specified time in the following cases:

Lamp missing

The lamp has burned out.

An unsuccessful attempt to light an old lamp operating in abnormal mode.

IZU price in this case, it increases by 40-60% of the price of conventional IZU, but an increase in cost in absolute terms by 30-50 rubles leads to a colossal gain in the operation of the entire PRA-IZU - Lamp system

Typically, IZUs are divided by lamp power: For example IZU 400— IZU 600, as well as the most modern, lamp base type E27, E14. The pulse amplitude ranges from 2.5 kV to 5 kV depending on the type of base and lamp power, which greatly increases its resource.

In total, all of the above can be defined as:

IZUs are divided into two types: parallel and serial1 Pulse igniters IZUfor DnaT, DRI, DNaZ, DRiZparallel type

Pulse igniters IZU are designed for igniting high-pressure discharge lamps of the DnaT (sodium arc) and DRI (metal halide arc) types with a power from 70 to 2000 W. The ignition mode of the lamps is provided by the IZU when switched on with an EMPA - Electromagnetic Start-Regulating Apparatus, a “choke” in the network alternating current rated frequency 50 Hz, 220-230V.

Distinctive feature from devices that are on the market:

a) high ignition ability;

b) the most low cost service.

2. Pulse ignition devices IZUfor DNAT, DRIserial type

Pulse ignition devices IZU are designed for igniting high-pressure discharge lamps such as DNaT, DRI with a power from 70 to 1000 W. The ignition mode of the lamps is provided by the IZU when switched on with an Electromagnetic Start-Regulating Device, a “choke” in an alternating current network with a nominal frequency of 50 Hz, 220-230V. A special feature of this IZU compared to those on the market is the use of cores for pulse transformers made of a special alloy from EPCOS, which is many times superior to similar cores in terms of technical characteristics.

Among all the lamps for artificial lighting For plants, a sodium lamp is most suitable, which is very popular.

This light source has high efficiency, and is the most economical and durable. The lamp power can range from 30 to 1000 W, depending on the area of use. As for the service life, the lamp life is designed for 25,000 hours of operation. For most greenhouses, this is a profitable option in terms of savings, since the plants need to be illuminated for quite a long time, especially in winter.

Are in great demand in the market Russian lamps Reflex, which are equipped with a built-in reflector. Due to this, the light is directed directly at the plants. The reflector of Reflux lamps has a high efficiency of 95%, which is maintained throughout the entire period of operation. Typically, one Reflax lamp with a power of 70 Watt, suspended at a height of half a meter, is capable of illuminating an area of about 1.6 m2. And since the use of other light sources implies high energy costs, the use of Reflux lamps is more rational. As for the dimensions, Reflax has dimensions of 76x200 mm. Thanks to this, Reflex lamps are best suited for greenhouse owners.

Advantages and disadvantages of sodium lamps

A sodium lamp has significant advantages:

• High efficiency.

• Stable light flow.

• High luminous efficiency of approximately 160 lm/W.

• Long service life, which is 1.5 times longer than the service life of other similar lamps.

• The lamps have a pleasant golden-white emission.

• Effective work in foggy conditions.

Due to the fact that the reflex 250 arc lamp emits a red spectrum, this ideal source light for flowering plants, including fruit-bearing ones. And the presence of a blue light spectrum contributes to their active growth and development. In addition, the lamps can operate in a wide temperature range - from -60 to +40 degrees.

Along with the advantages, there are also some disadvantages. The main one is the complexity of the connection. The usual method is not suitable here, and there are some peculiarities here. Other disadvantages include the following:

• Explosion hazard.

• Presence of mercury in the lamp structure.

• Long turn-on time, which can be up to 10 minutes.

• Not suitable for growing non-flowering or green vegetable crops(radish, onion, lettuce).

In addition, if it is necessary to use high-pressure sodium lamps of 250 watts or more, care must be taken to ensure cooling as the lamps become very hot. Although for greenhouses big size this disadvantage can turn into an advantage by providing the plants with additional heat.

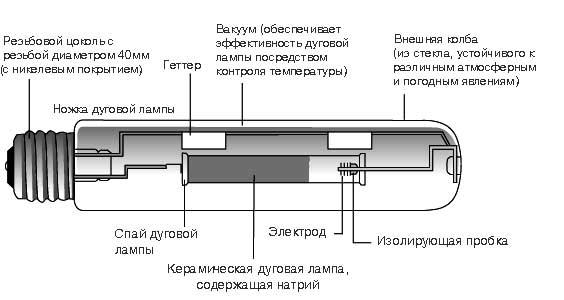

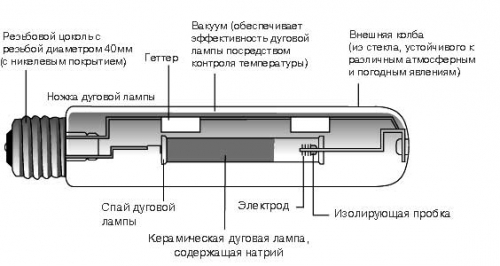

Principle of operation

By appearance Sodium light sources are a bit like DRL lamps. There is also a glass flask of an elliptical or cylindrical shape; inside it there is a discharge tube (“burner”), on each side of which there are electrodes. These pins are connected to threaded base. Due to the fact that sodium vapor has a strong effect on glass, this material is not suitable for making a “burner”. It is made from polycor (polycrystalline aluminum oxide), which increases resistance to sodium vapor and transmits up to 90% of visible light. The DNAT 400 lamp has a discharge tube with a diameter of 7.5 mm and a length of 80 mm. The tube electrodes are made of molybdenum.

In addition to sodium vapor, the discharge tube composition contains argon to facilitate starting the lamps, and also contains mercury or xenon, which allows for increased luminous efficiency. During operation, the “burner” heats up to 1300 °C and in order to keep it intact, air is pumped out of the flask. However, it is difficult to maintain a vacuum while the lamp is running, as air can enter through the holes. Therefore, special gaskets are used to prevent this. It is worth noting that when the lamp is operating, its bulb heats up to 100 °C. When the pulse ignition device (IZD) is turned on, a pulse voltage is created, resulting in the formation of an arc. But at first, the sodium lamps DNAT reflex 250 still shine weakly, since all the energy is spent on heating the tube. After 5 or 10 minutes, the brightness of the light returns to normal.

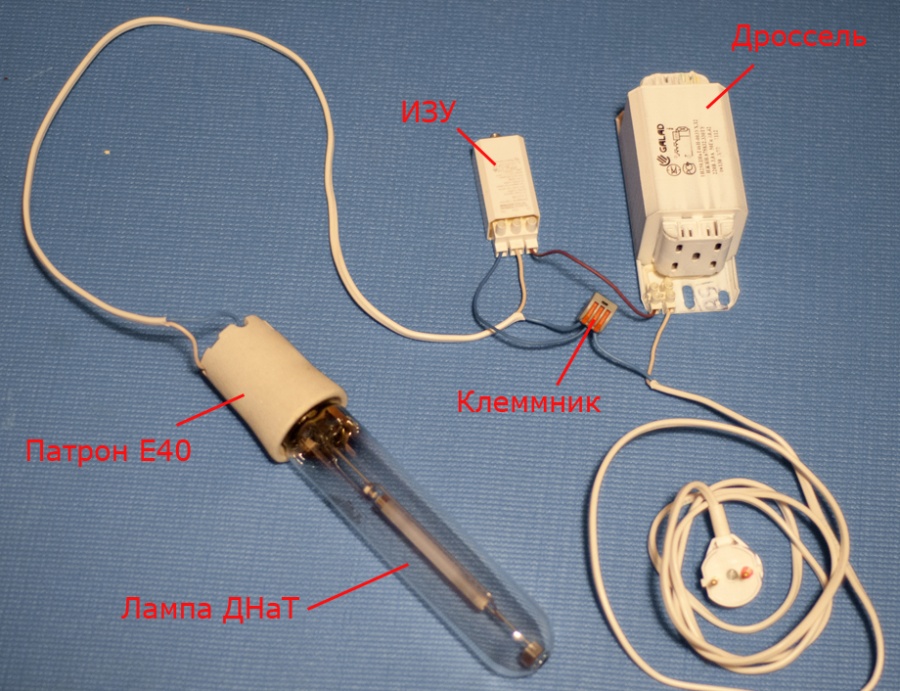

How to connect a sodium lamp

Due to the special structure of gas-discharge lamps, it is not possible to simply connect them to a household electrical network, since the available voltage is not enough to start. In addition, the arc current must be limited. And sodium lamps are no exception. In this regard, it is necessary to use a ballast or ballast in the circuit. They can be electromagnetic (EMP) or electronic (EPG). In practice Western countries such devices are called Magnetic Ballast (for electronic ballasts) and Digital Ballast (for electronic ballasts). In some cases, it is impossible to do without the use of a pulse ignition device or IZU.

The use of electronic ballasts for sodium lamps 250 is necessary for their heating and further uninterrupted operation. In this case, the launch itself takes 3-5 minutes, and full power sodium lights are dialed in for another 10 minutes. It is noteworthy that at the time of startup of the lamp its Rated voltage increases almost 2 times.

Ballast device

The ballast consists of three main components:

• Inductive choke.

• IZU.

• Phase compensating capacitor.

The choke serves to limit the arc current and its power must be the same as that of the lamp used. For example, if a HPS 250 lamp is used, then, accordingly, the power of the inductor should also be no less and no more than 250 Watts. IN Lately The lamp connection diagram often includes a single-winding choke, while double-winding ones are already obsolete.

IZU is necessary to increase the voltage to several kilovolts in order to form an arc. The power of the IZU can range from 35 to 400 Watts. In addition, the device can be of a two-pin or three-pin design. Moreover, the use of three-pin IZU is preferable.

As for the capacitor, this is an optional component. But its presence provides certain advantages, as it allows you to reduce the load on household electrical network. In turn, this reduces the risk of a wiring fire to a minimum. More details will be discussed below.

Connection diagrams for HPS lamps

Depending on which IZU is used (with two terminals or three), 250 Watt high pressure sodium lamps can be connected in different ways. This is reflected in more detail in the diagram below.

Sodium lamp connection diagram

Sodium lamp connection diagram As you can see from the figures, the inductor (ballast) is connected in series, but the IZU is connected to the circuit in parallel.

To operate, sodium lamps use reactive power. In this regard, it is desirable that the connection diagram include a special capacitor, which will suppress interference and reduce the inrush current. Which ultimately extends the life of the lamps. Also, this element is simply irreplaceable in the absence of a phase compensator.

As can be seen in the first figure, the presence of a phase-compensating capacitor is shown by a dotted line. Its connection is carried out in parallel with the power source.

The main thing is to choose a capacitor with optimal electrical capacity. For example, when using the same DNAT-250 lamp, its capacity should be 35 microfarads. If the circuit contains a DNaT 400 lamp, then you can choose a capacitor with a slightly larger capacity - 45 μF. Only dry elements and those designed for a voltage of at least 250 V are allowed to be used in the circuit.

At self-connection lamps is worth taking note of. The length of the wire connecting the light source itself and the inductor should not exceed one meter.

Precautionary measures

By virtue of design features 250 sodium discharge lamp, extreme caution must be used when operating these light sources. It is unacceptable to turn off the lamp immediately after turning it on. It should remain on for at least 1 or 2 minutes. Otherwise, the lamp will stop turning on altogether and then it must be de-energized and wait a while.

In the room where lamps operate, it is necessary to have high-quality ventilation. Its temperature during operation can rise to 100 degrees or more. And according to some sources, all 1000. Therefore, good ventilation is the key to long and safe work lighting sources. Do not touch high-pressure lamps with your hands during operation to avoid burns. The same goes for its reflector.

When installing lighting sources, you do not need to handle the bulb with bare hands; it is best to use cloth gloves. Or you can wrap it in some paper or cardboard to avoid leaving greasy fingerprints on the glass. Since the heating temperature is very high, any grease deposits or even drops of water can cause the lamp to explode. You can find a lot of information about this on the Internet.

But not only high-pressure lamps can get very hot, this also applies to the ballast used. Its temperature can rise to 80-150 degrees. Therefore, as a precaution, this element of the circuit should be insulated, hidden under a fireproof and durable casing. This will prevent dry leaves, pieces of fabric or paper, and other objects from getting inside.

Don’t forget about basic safety precautions when working with electricity. That is, eliminate any possibility of water getting into the ballast, and monitor the integrity of the electrical wiring. It is always worth remembering that at the moment when the HPS lamp starts, the IZU generates high voltage pulses. Therefore, it is best to use special wires that are designed to work in extreme conditions. They are just designed for high heat.

Disposal

Sodium, by its nature, is a volatile substance and, in contact with air, can ignite rapidly. For this reason, sodium light sources should not be disposed of as regular waste. Like any Powersave lamp, which contains mercury, they also need to be disposed of in special containers. If you cannot dispose of HPS sodium lamps yourself while observing safety precautions, you should call a special service.

Sodium lamps, compared to other artificial lighting sources, demonstrate the highest efficiency - close to 30%. To save money Money It is recommended to buy high pressure bulbs. The light emitted by high-pressure sodium lamps allows one to distinguish colors in almost the entire range, excluding only short-wavelengths, in which the color fades somewhat. Let's talk today about the emergence, use and connection of sodium lamps with our own hands.

Historical reference

The biggest contribution to street lighting has come from high-pressure sodium discharge lamps, which are a major hindrance to astronomical observations. Let's delve into history to understand what they are. Tubular lamps, which exhibit low mercury pressure, were invented in the pre-war period.

Similar fluorescent lamps quickly became widespread. But it was not possible to obtain a discharge in sodium vapor for a long time, this was explained by the low partial pressure sodium at low temperature. After a complex of technological tricks, sodium lamps were created that operated at low pressure. But due to their complex design, they were not widely used.

But the fate of sodium lamps, which operate at high pressure, was more successful. All initial attempts to create lamps in a quartz glass shell ended in failure. At high temperature The chemical activity of sodium increases and, as a result, the mobility of its atoms increases. Therefore, sodium in quartz burners penetrated quickly through the quartz, destroying the shell.

The emergence of sodium lamps

The situation changed radically in the early sixties, when the General Electric company patented a previously unknown ceramic material, which is capable of working in sodium vapor at high temperatures. It received the name “lukalos”. In our country, this ceramics is known to the inhabitants as “polycor”.

This ceramic is produced by high-temperature sintering of aluminum oxide. For lighting purposes, only one modification of it is considered suitable. crystal lattice- the alpha form of the oxide, which has the densest packing of atoms in the crystal.

The sintering process of such ceramics is very capricious, because it must be chemically resistant to sodium vapor and must have high transparency so that it does not get lost in the walls of the discharge tube. most of Sveta. Sodium vapor, which serves as a gas-discharge medium in sodium lamps, produces a bright orange light when illuminated. Because of the presence of sodium in the lamp, the abbreviation DNAT came into use, which means sodium arc lamps.

Advantages and disadvantages of sodium lamps

Sodium lamps are twice as effective as regular lamps daylight similar power - this can be explained by the small size of the emitter, the light rays from which are much easier to direct into the right side and other design features.

In addition, with the help of sodium arc lamps you can recreate much greater illumination. Its ceiling for daylight fixtures reaches 50 watts per square foot, and with the help of sodium lamps you can achieve 3 times more without any problems!

From an economic point of view, sodium lamps are more profitable - they only need to be changed once every six months, and 1 DNAT-400 lamp can successfully replace 20 40 V LDS. It is also much more convenient to work with a medium ballast than with 15 small ones. Since sodium lamps use electricity twice as efficiently, when using them, a certain result is achieved at half the cost.

The efficiency of sodium light bulbs is directly dependent on temperature external environment, and this in turn slightly limits their use, because they shine worse in cold weather. It is also not entirely clear that they are more environmentally friendly than mercury lamps, since most sodium lamps use a sodium and mercury compound as a filler - sodium amalgam.

Using sodium lamps

Typical objects where sodium lamps are used: highways, streets, squares, long-haul tunnels, airfields, traffic intersections, athletic facilities, construction sites, airports, train stations, architectural structures, warehouse and industrial premises, pedestrian areas and roads, as well as additional lighting sources.

If you want yours personal plot somehow decorate, then you can buy sodium lamps, which were found in landscape design its application. Due to the characteristics of sodium lamps, warm and bright orange light, they are used for auxiliary purposes for a unique decorative effect, which simulates an open flame or sunset.

Purchasing sodium lamps is useful if the owner grows seedlings and has winter Garden, greenhouse or conservatory. Of course, sodium lamps natural light and the light of the sun will not replace, but your plants will not be affected in any way by changes in weather conditions and cloudy days, provided that the flowers are illuminated with such lamps.

Operating principle of a sodium lamp

Inside the external cylinder of DNAT there is a “burner” - a tube that is made of aluminum ceramics and filled with rarefied gas, in which an electric arc is created between two electrodes. Sodium and mercury are introduced into the burner, and in order to limit the current, an inductive ballast or electronic ballast is used .

The mains voltage is not enough to ignite a cold sodium lamp, so the principle of operation of a sodium lamp is to use a special IZU - a pulsed ignition device. Immediately after switching on, it generates voltage pulses of several thousand volts, which are guaranteed to create an arc. The main radiation flux is generated by sodium ions, so their light has a characteristic yellow color.

The burner heats up to 1300 degrees Celsius during operation, so air has been pumped out from the external cylinder to keep it intact. For all sodium lamps without exception, when operating, the temperature of the cylinder exceeds 100 degrees Celsius. The lamp shines weakly after the arc occurs, all energy is spent on heating the burner. The brightness increases as it warms up and after ten minutes reaches normal levels.

Types of sodium lamps

If the economical operation of light over a long time is more important to you, then it is best to purchase low-pressure sodium lamps, which are characterized by high levels of operational reliability, light output over a long time and energy efficiency.

Sodium lamps are ideal for organizing street lighting because they are capable of emitting the monochrome color familiar to people. yellow, but do not have sufficient transmission of the light spectrum.

For other purposes, the use of low-pressure lamps is considered difficult because the colors of objects illuminated by such a lamp cannot be distinguished. Color perception of objects in indoors distorted (for example, green color turns into dark blue or black), and the design appearance of the premises is lost.

To save money, it is recommended to buy high-pressure sodium lamps. Connecting high pressure sodium lamps is most suitable for gyms, industrial and commercial complexes. The light emitted by high-pressure sodium lamps allows colors to be distinguished in almost the entire range, except for short wavelengths, in which colors may fade somewhat.

Installation of sodium lamps

Sodium lamps are now widely used in various sectors of the economy, however, due to insufficient transmission of the color spectrum, they are most often used as street lighting. Sodium bulbs, unlike metal halide bulbs, do not care in which position they operate.

However, based on many years of practice, it is believed that the horizontal position of the lamp is more effective, because it emits the main flow of light to the sides. To connect any HID lamp, a ballast is required. Sodium lamps are no exception in this sense; ballast is required for their “warming up” and normal operation.

Ballast

For sodium lamps, the ballast is a ballast, electronic ballast and pulse ignition device. Undoubtedly, the best ballasts are rightfully considered electronic, which have a number of advantages over inductive ballasts, losing to the latter in cost: currently their price is quite high.

The most common ballasts are ballast inductive chokes, which are necessary to limit and stabilize the current. The necessary ballast, which is connected to the lamp in the required way, is already present in them, so the connection diagram for sodium lamps comes down solely to supplying supply voltage to the terminals of the lamp.

Today, double-winding chokes are outdated, so you should give preference to single-winding ones. Regular throttle domestic production You can buy it at the company for about 10 dollars, and at the market - half the price.

It must be intended specifically for HPS and have the same power as the lamp. It is necessary to install a “original” choke, otherwise the lamp’s service life may be reduced several times, or the light output will drop catastrophically. It is also possible to “blink” when the sodium lamp goes out immediately after warming up, then cools down, and everything happens all over again.

Pulse ignition device

IZUs are required, as described above, to light the lamp. IZU manufacturers produce devices with 2 and 3 pins, so the sodium lamp switching circuit may be slightly different. But usually it is depicted on each IZU case. Of the domestic IZUs, the most convenient is the “UIZU”; it is suitable for lamps of any power and can work with all ballasts.

![]()

In this case, you can place the UIZU next to the ballast and near the light bulb, connecting it to its contacts. Polarity does not play a special role when connecting the ICU, but it is recommended that the “hot” red wire be connected to the ballast.

Noise suppression capacitor

Arc sodium lamps are consumers of reactive power, so it makes sense in some cases (in the absence of phase compensation) to include an interference suppression capacitor C in the sodium lamp circuit, which significantly reduces the inrush current and prevents unpleasant situations. For chokes DNaT-250 (3A), the capacitance of the capacitor should be 35 μF, for chokes DNaT-400 (4.4A) - reach 45 μF. Dry type capacitors with a rated voltage of 250 V should be used.

Connections are usually made thick stranded wire large section, network cable must also count on high current. Make solderings reliable. Tighten the screws tightly, but without excessive force, so as not to break the block.

When connecting sodium lamps yourself, it is worth considering this recommendation - you should not allow the length of the wires that connect the ballast to the sodium lamp to exceed more than one meter.

Security questions

If you assembled the lamp yourself, make sure that its connection diagram is absolutely correct. If the connection diagram is not drawn on your ballast, or the number of legs on the ballast/IZU does not match the diagram, you should consult with the seller of these parts or experienced electrician. The consequences of such an error are catastrophic: burnout of one of the 3 elements of the circuit, knockout of plugs, explosion of the lamp and fire.

If there is grease or dirt on the sodium lamp cylinder, it may burst due to uneven heating immediately after warming up. Therefore, do not touch the lamp with your hands and wipe it with alcohol just in case after installing it in the socket. If drops of water or other liquids come into contact with a switched-on lamp, this provokes an explosion with 100% probability!

When using a fan, it is worth checking that it blows and rotates where it should. The lamp must be hung securely to avoid falling - a sodium lamp is heavy and can break something if dropped. When repairing a lamp, some measurements should be made with the device turned on - do not do this yourself unless you have sufficient experience working with high voltage equipment.

While the sodium lamp is operating, once a month, wipe off dust from the lamp and reflector and check the condition of the fan. It is recommended to change sodium lamps every 4-6 months, since towards the end of their useful life their light output drops significantly.

Sodium lamp malfunctions

As sodium lamps age, they acquire the habit of “blinking”: the lamp turns on, warms up as usual, then goes out unexpectedly, and everything repeats after a while. If you notice this behavior in your lamp, you should try changing the light bulb. If changing the lamp does not help, you need to measure the voltage in the network; maybe it is slightly lower than usual.

If the sodium lamp blinks irregularly, the reason lies in poor contact or power surges in the network. The most unpleasant situation is a short circuit in the ballast between the turns of the winding, then it needs to be changed. Sometimes new lamps may flash, but this goes away after a few hours.

You can often hear the IZU crackling after turning on the lamp (a sign of operation), but the lamp does not even try to light up. This happens most often due to breakdowns in the wire that goes to the lamp from the IZU, or indicates a burnt-out lamp. A broken wire between the lantern and the ballast or a burnt IZU may be to blame.

You can try changing the wire between the lamp and the IZU. It is also worth paying attention to the IZU contacts and their condition. If it doesn't help, change the lamp. If this does not help, turn off the IZU, because it can burn the voltmeter with its impulses, and measure the voltage on the lamp socket - it should correspond to the mains voltage at the DNAT. If there is voltage on the cartridge, change the IZU.

If the sodium lamp shows no signs of life at all: the IZU does not buzz, the lamp does not glow - most likely the contact in the power cord is broken or the fuse is blown out. Maybe the IZU burned out, or a winding break occurred in the ballast - check the ballast, if it is intact, it is worth changing the IZU.

The ballast can be checked with a regular Ohm meter. Their normal resistance is 1-2 ohms. If the indicator is significantly higher, it means that there was a break in the winding or the contact between the connecting block and the winding terminals was broken (tighten the screws).

Everything is more complicated with interturn closure - it affects the resistance DC very little, so it is difficult to detect, and more power is supplied to the lamp than necessary. When a sodium lamp is overpowered, the lamp overheats quickly and goes out, and as a result, “blinking” can also be observed.

Now you know how to connect sodium lamp! In conclusion, it is worth noting that sodium arc lamps represent one of the most efficient categories of visible radiation sources, because they are characterized by the highest light output of all known to mankind gas discharge lamps and a slight decrease luminous flux with a long useful life.

To ignite gas-discharge lamps, including sodium lamps, you will need specialized ballast equipment (ballast control equipment), because direct connection of HPS lamps to the network is excluded.

Ballasts for sodium lamps (HPS) include:

- IZU (pulse ignition device), which ensures the start of a gas-discharge lamp. At the moment it is turned on, the IZU transmits powerful high-voltage pulses to the electrodes, due to which a breakdown occurs in gas mixture bulbs and arc ignition. After this, the issuance of explosive pulses stops, however, as does the influence of the pulse ignition device on the operation of the lamp;

- Throttle. Although electronic ballasts are considered more productive, their cost is much more expensive than pulsed ones. Therefore, the most common and in demand for connecting a HPS lamp is an inductive choke. The electric choke is presented in the form of a small block, which must correspond to the power consumption of the lamp. It limits and stabilizes the current supply, strongly resists any changes, maintains a decreasing current and prevents its increase, thereby ensuring long-term performance properties of the lamp and high luminous efficiency.

Thus, the ballast provides standard heating and effective work sodium lamps for the entire period stated by the manufacturers.

HPS connection. Scheme

Possible different methods connections of gas-discharge lamps, in this case HPS: IZU manufacturers can offer a design with two or even three contacts, with a parallel, serial and even semi-parallel type, which significantly changes the HPS connection scheme. It is displayed on almost all devices of this type, which eliminates installation errors.

The connection diagram for the HPS lamp, which is shown in the first figure, is designed to contain a compensating capacitor connected in parallel to the power source. This is a dry type C capacitor, which is designed to compensate for the inductive component of the system - reducing reactive power consumption, reducing overall electricity consumption, as well as extending the service life of the finished product.

For example, to connect a HPS lamp with a power of 250 W (3A), a compensating capacitor capacity is provided (operating voltage indicators are 250V) of only 35 μF. This capacitance can be formed using several capacitors connected in parallel.

Sometimes capacitance indicators may be provided by the manufacturer, but an extremely large increase can lead to resonance in the circuit, and, consequently, to ineffective operation of the finished product.

If the HPS connection occurs independently, the permissible value of the location of the IZU should be taken into account. It should be located as close as possible to the base of the product, while the length of the connecting wires in this area should be minimal (the maximum permissible value is 1.5 m).

To ensure a high-quality and safe connection, high-voltage ignition wires for special purposes are used.

Reviews

Guest- 07 Feb 2014 23:58:53

In my opinion, the phase in the lamp is where you have zero.

Igor- 08 Feb 2014 14:56:03

In fact, the lamp will work well with any connection of phase and zero to its base.

But there is a safety issue.

And here you are right.

The pictures do not show the socket into which the lamp is screwed.

For clarity, I omitted it from the diagram.

Assuming that you are unscrewing a burnt-out lamp and at the same time:

1.phase is connected to the threaded part of the cartridge (as in the pictures)

2.You forgot to turn off the switch, or it opens zero, not phase

Then when you touch the base you will get a good knock.

And if the phase is connected to the central contact of the base, then the chance of electric shock is minimal.

But personally, I would unscrew the lamp while holding onto its glass bulb. When the power is off. And I wouldn’t think about the connected phase.

But anyway, thanks for the clarification.

Vitaly- 18 Feb 2014 8:57:24

And what should the phrase “...IZU manufacturers can offer a design with two or even three contacts...” mean? All normal manufacturers of sodium lamps, Philips, OSRAM, General Electric, launch their sodium lamps exclusively in series or semi-parallel circuits, with the exception of lamps with a built-in ignitor. And this means the presence of exactly three contacts. A parallel ignitor (which has two contacts) cannot be used to start such lamps, since the vast majority of ballasts do not have protection against high-voltage pulses and will fail very quickly. Therefore, parallel connection used to start low-pressure sodium lamps or metal halide lamps designed to work with mercury ballast and do not require high-voltage starting pulses. Based on this, I undertake to assert that scheme No. 2, made up of precisely these components, is not correct. The VS catalog, whose ballast is used for the example, can confirm this. The DeLux ignitor was used to start sodium lamps only in combination with a ballast specially produced for this circuit.

What am I doing wrong?

Alexei- 02 Oct 2014 23:16:14

Hello, could you please tell me the connection diagram for the Philips sox-e 131w low pressure lamp?

When using a conventional circuit with a two-pin Izu starts to twitch, but does not flare up

Guest- 04 Nov 2014 11:48:27

everything lights up perfectly with any ignitor connection diagram, both parallel and serial 3-pin!!!

Sergey- 29 Nov 2014 10:08:52

Good afternoon, could you please tell me the connection diagram:

1 gas-discharge sodium lamp lhp-t 100 W

2 isut 70-700DNaT/220v-02.ukhl2 (2 contacts)

3 ballast galad 1i250drl44-033uhl1 (three contacts, and they are marked 1 2 3)

thank you in advance