What are the parts of a light bulb called? See what "Electric lamp" is in other dictionaries

A body heated by an electric current can, it turns out, not only radiate heat, but also glow. The first light sources functioned precisely on this principle. Consider how an incandescent lamp works - the most massive lighting fixture in the world. And, although it will eventually have to be completely replaced by compact fluorescent (energy-saving) and LED sources light, without this technology humanity will not do for a long time.

Incandescent lamp design

The main element of the light bulb is a spiral of refractory material - tungsten. To increase its length and, accordingly, resistance, it is twisted into a thin spiral. This is not visible to the naked eye.

The spiral is fixed on supporting elements, the outermost of which serve to attach its ends to electrical circuit. They are made of molybdenum, the melting point of which is higher than the temperature of the heated coil. One of the molybdenum electrodes is connected to the threaded part of the base, and the other to its central terminal.

Molybdenum holders hold the tungsten coil

Air is evacuated from a flask made of glass. Sometimes an inert gas, such as argon or its mixture with nitrogen, is pumped inside instead of air. This is necessary to reduce the thermal conductivity of the internal volume, as a result of which the glass is less susceptible to heat. Additionally, this measure prevents oxidation of the filament. During the manufacture of the lamp, air is pumped out through a part of the bulb, which is then hidden by the base.

The principle of operation of an incandescent lamp is based on heating its filament with an electric current to a temperature at which it begins to emit light into the surrounding space.

Incandescent lamps can be manufactured for power from 15 to 750 watts. Depending on the power used different types screw bases: E10, E14, E27 or E40. For decorative, signal and backlight lamps, BA7S, BA9S, BA15S socles are used. Such products, when installed, are stuck inside the cartridge and rotated 90 degrees.

In addition to the usual, pear-shaped form, decorative lamps are also produced, in which the bulb is made in the form of a candle, a drop, a cylinder, a ball.

A lamp with a bulb that does not have a coating glows with a yellowish light, most reminiscent of sunlight in composition. But when applied to inner surface glass with special coatings, it can become matte, red, yellow, blue or green.

Of interest is the device of a mirror incandescent lamp. A reflective layer is applied to part of its bulb. As a result, due to reflection from it, the luminous flux is redistributed in one direction.

Advantages of incandescent lamps

by the most an important plus in favor of the use of incandescent bulbs is the simplicity of their manufacture and, accordingly, the price. Easier lighting device impossible to imagine.

Lamps are manufactured for a wide range of power and overall dimensions. Other contemporary sources lights contain devices that convert the supply voltage to the value necessary for their operation. Although they manage to shove them into the standard dimensions light bulbs, but at the same time the design becomes more complicated, the number of parts in the device increases. And this does not always improve the cost and reliability indicators. The circuit for switching on an incandescent lamp does not require any additional elements.

light diode lamps replaced conventional ones from portable devices: portable light sources powered by batteries and accumulators. With the same light output, they consume less current, and the overall dimensions of the LED are even smaller than the bulbs previously used in flashlights. Yes, and as part of Christmas tree garlands, they work more successfully.

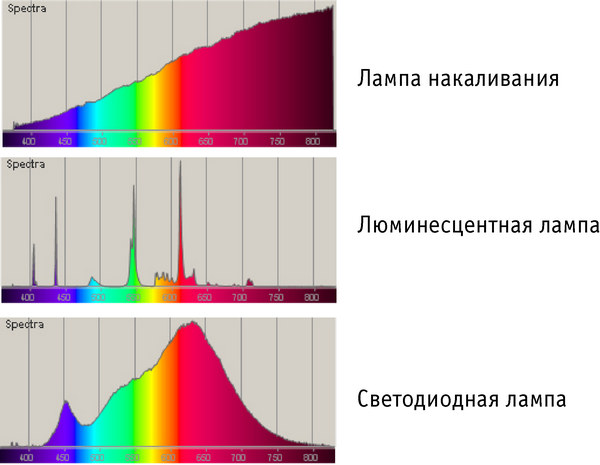

It is worth noting one more advantage inherent in incandescent bulbs - their luminescence spectrum is closest to the sun than that of all other artificial light sources. And this is a big plus for vision, because it is adapted specifically to the sun, and not to monochrome LEDs.

Due to the thermal inertia of the heated filament, the light from it practically does not pulsate. What cannot be said about radiation from other devices, especially luminescent ones, using a conventional choke as a ballast, and not a semiconductor circuit. Yes, and electronics, especially cheap ones, do not always suppress ripples from the network properly. This also affects the eyesight.

But not only health can be damaged by the pulsating nature of the operation of semiconductor devices used in modern lamps glasses. Their massive use leads to a sharp change in the shape of the current consumed from the network, which ultimately affects the shape of the voltage. It changes so much in relation to the original (sinusoidal) that this affects the quality of the work of other electrical appliances in the network.

Disadvantages of incandescent lamps

A significant drawback of incandescent bulbs, which reduces their service life, is its dependence on the magnitude of the supply voltage. As the voltage increases, the filament wears out faster. They produce lamps for different values \u200b\u200bof this parameter (up to 240 V), but at the nominal value they shine worse.

Lowering the voltage leads to a sharp change in the intensity of the glow. And even worse, its fluctuations affect the lighting device; with sharp jumps, the lamp may burn out.

But the worst thing is that the filament is designed to work for a long time in a heated state. When heated it resistivity increases. Therefore, at the moment of switching on, when the thread is cold, its resistance is much less than that at which the glow occurs. This leads to an inevitable current surge at the moment of ignition, leading to the evaporation of tungsten. The greater the number of inclusions, the less the lamp will live.

Soft start devices or devices that allow you to adjust the brightness of the glow over a wide range help to correct the situation.

The main disadvantage of incandescent bulbs is their low coefficient useful action. The vast majority of electricity (up to 96%) is spent on useless heating of the surrounding air and radiation in the infrared spectrum. Nothing can be done about this - this is the principle of the incandescent lamp.

And one more thing: the glass of the flask is easy to break. But unlike compact fluorescent lamps containing a small amount of mercury vapor inside, a broken incandescent lamp does not threaten the owner with anything other than a possible cut.

Halogen lamps

The reason for the burnout of an incandescent lamp is the gradual evaporation of the tungsten from which the filament is made. It becomes thinner, and then another surge of current when turned on melts it at its thinnest point.

This drawback is designed to eliminate halogen lamps filled with bromine or iodine vapor. During combustion, the evaporating tungsten combines with halogen. The resulting substance is not capable of depositing on the walls of the flask or other relatively cold internal surfaces.

In the vicinity of the filament, the tungsten is removed from the joint by the action of temperature and returned to its place.

The use of halogens solves another problem: the temperature of the spiral can be raised, increasing the light output and reducing the size of the lighting device. Therefore, with the same power, the dimensions of halogen lamps are smaller.

By definition, an incandescent lamp is electrical source light, where the incandescent body, which is usually a refractory conductor, is inside a bulb, evacuated or filled with an inert gas, and heated to a high temperature with the help of an electric current that is passed through it. As a result, visible light is emitted. For the filament, a tungsten-based alloy is used.

incandescent lamp general purpose(230 V, 60 W, 720 lm, base E27, overall height approx. 110 mm

The principle of operation of an incandescent lamp

Well, everything is very simple here. An electric current passes through the incandescent body and heats it up. The filament emits electromagnetic heat radiation, which is in accordance with Planck's law. Its function has a maximum depending on temperature. If the temperature rises, then the maximum shifts towards shorter wavelengths. To get visible radiation, the temperature must be several thousand degrees. For example, at a temperature of 5770 K (such a temperature on the surface of the Sun), the light will correspond to the spectrum of the Sun. If the temperature decreases, then there will be less visible light, and the radiation will be red.

But only part of the energy is converted into radiation, the rest is spent on heat conduction and convection. A small fraction of the radiation is in the field of view, and everything else falls on infrared radiation. In order to increase the efficiency of the light bulb and thereby obtain "white" light, it is necessary to increase the temperature of the filament, but its limit is limited by the properties of the material. For example, it will not be able to withstand a temperature of 5771 K, since any of known to man materials at this temperature begins to melt, break down, or simply does not conduct electricity. Now incandescent lamps are equipped with a filament that can withstand the maximum melting point. This is mainly tungsten, which can withstand 3410 ° C, and less often osmium with a limit of 3045 ° C.

The quality of light is evaluated using color temperature. An ordinary incandescent light bulb has a temperature of 2200 - 3000 K and radiates at the same time yellow, which is far from daytime.

But in air, tungsten is not able to withstand such a temperature. It instantly turns into an oxide, so you need to create special conditions. When creating a lamp, air is pumped out of the bulb, but only low-power lamps (up to 25 W) are made using this technology in our time. The flasks of more efficient lamps contain an inert gas (usually nitrogen, argon or krypton). Due to the high pressure, tungsten does not evaporate so quickly. It also increases the service life and allows you to increase the temperature of the glow, and this increases the efficiency and allows you to get closer to the white spectrum of radiation. Gas-filled lamps do not darken as quickly from the deposition of filament material than vacuum lamps.

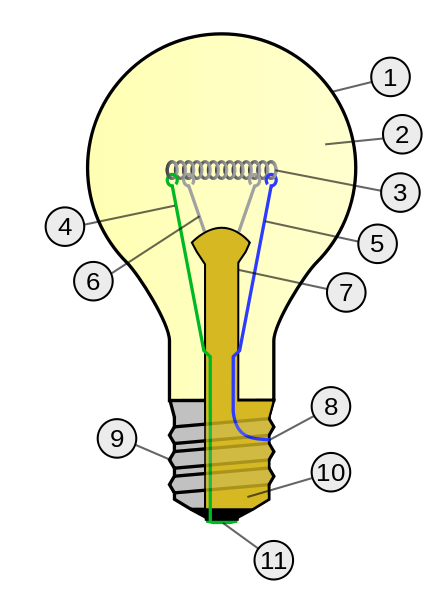

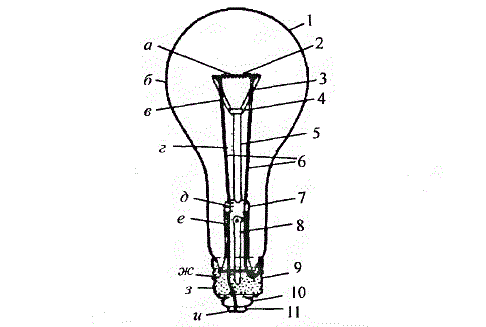

What is an incandescent lamp made of? Now we'll find out. In general, their design depends on the purpose, but the main elements are the bulb, the filament body and the current leads. Lamps are made for specific purposes, so some may have unusual filament holders, or may not have a cap, or a different size cap, or extra bulb. IN simple lamps you can find a fuse - this is a link consisting of a ferronickel alloy and welded into the gap of one of the current leads. This link is usually located in the leg. Its purpose is to prevent the bulb from collapsing when the filament breaks. When the filament breaks, an electric arc is formed that can melt the remaining filament. Molten metal can damage the glass and cause a fire. And thanks to the fuse, this can be avoided, since it is destroyed when an arc occurs, the current of which is several times higher than rated current lamps. The ferronickel link is located in the cavity, where the pressure is equal to atmospheric, so the arc goes out without problems. The low efficiency led to the fact that they had to be abandoned.

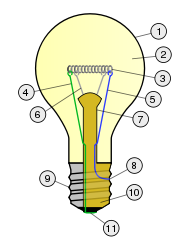

The design of the incandescent lamp: 1 - bulb; 2 - the cavity of the flask (vacuum or filled with gas); 3 - glow body; 4, 5 - electrodes (current inputs); 6 - hooks-holders of the body of heat; 7 - lamp leg; 8 - external link of the current lead, fuse; 9 - base case; 10 - base insulator (glass); 11 - contact of the bottom of the base.

The design of the incandescent lamp: 1 - bulb; 2 - the cavity of the flask (vacuum or filled with gas); 3 - glow body; 4, 5 - electrodes (current inputs); 6 - hooks-holders of the body of heat; 7 - lamp leg; 8 - external link of the current lead, fuse; 9 - base case; 10 - base insulator (glass); 11 - contact of the bottom of the base.

Flask

Thanks to the flask, the filament body is protected from atmospheric gases. To determine the size of the bulb, you need to know at what rate the filament material will be deposited.

Gas medium

Initially, the lamps were evacuated. In our time, the lamps contain an inert gas (excluding lamps with low power). The higher the molar mass of a gas, the less heat is lost through conduction. The most popular gas mixture includes nitrogen N2 and argon Ar (due to low cost). Pure dried argon, xenon Xe or krypton Kr can also be used.

Molar masses of gases:

- N2 - 28.0134 g/mol;

- Ar: 39.948 g/mol;

- Kr - 83.798 g/mol;

- Xe - 131.293 g/mol;

To a special group of lamps should be attributed halogen, since halogens or their compounds are introduced into their flask. The filament body material evaporates and combines with the halogens. Thermal decomposition of such compounds allows the material to return to the surface of the thread. Due to this, the lamp has a higher temperature of the filament, greater efficiency, longer life and a smaller bulb. The main disadvantage is the low electrical resistance in the cold state.

Glow body

The heating body may have different forms, which depend on the purpose of the light bulb. A body made of wire of a circular cross section is more popular, but there can also be filament bodies (made of metal ribbons). That is why saying "filament" will not be entirely correct.

The first light bulbs used coal (sublimation temperature 3559 °C). Nowadays, a tungsten or osmium-tungsten alloy spiral is used. The shape of the spiral allows you to reduce the size of the filament body. The helix can undergo repeated or even tertiary helix (bi-helix or tri-helix). This allows you to increase the efficiency of the lamps, reducing heat loss due to convention.

Electrical parameters

Because the lamps are various purpose, and their operating voltage is different. The strength of the current can be determined by the law Ohm (I=U/R) and power according to the formula P=U I, or P=U²/R. To achieve the desired resistance, a long and thin wire, the thickness of which is 40 - 50 micrometers.

At the switched off light bulb, the filament body has room temperature, therefore, when turned on, a very large current passes (somewhere 10-14 times more than the operating current). The current decreases only when the filament heats up and the resistance increases. For example, before it was the other way around. Lamps with carbon filaments, when heated, reduced the resistance and slowly increased the glow.

For independent flickering of the lamp, a bimetallic switch is installed in it in series with the filament.

plinth

The threaded plinth we all know was proposed by Joseph Wilson Swan. Plinth sizes are standardized. Usually on the farm there are Edison socles E14 (minion), E27 and E40 (the number means outside diameter in mm). There are bases without threads (in this case, the lamp is held in the cartridge by friction or non-threaded mating, for example, bayonet) - the British standard and, in general, baseless lamps, for example, in a car.

In the USA and Canada, other socles are used, since the mains voltage can be 110 V, so they changed the size of the socle (E12 (candelabra), E17 (intermediate), E26 (standard or medium), E39 (mogul)) so as not to screw in by mistake European lamps. They also use non-threaded plinths.

Incandescent lamp efficiency

Almost all of the energy that is supplied to the lamp is spent on radiation, and only a part is spent on heat conduction and convection. Our eyes see only in a narrow range of wavelengths (the range of visible radiation), but the main radiation power is in the infrared range, which we cannot see and perceive as heat. That's why lamp efficiency incandescent at a temperature of 3400 K is 15%. At a temperature of 2700 K (this is a regular 60 W light bulb), the efficiency is only 5%.

The higher the temperature, the greater the efficiency, but the durability is significantly reduced. If the temperature reaches 2700 K, then the lamp will last 1000 hours, but if the temperature of the filament is increased to 3400 K, then the bulb will last only a few hours. If you raise the voltage by 20%, then the brightness will increase by 2 times, but the service life will drop by 95%.

Low voltage, of course, lowers the efficiency, but the light bulb will last longer. If you lower the voltage (series connection), then the efficiency will drop by 4-5 times, but the lamp will last almost a thousand times longer. This version of work is very effective if there are no special requirements for lighting, for example, on landings. The lamp is connected in series with the diode and an alternating current is started, then the current in the lamp will flow only half the period. This will reduce the power by 2 times, and therefore the voltage will decrease by ~ 1.41 times.

If we consider this from an economic point of view, then increasing the durability by lowering the voltage is completely unprofitable, since during the service life the cost of the electricity consumed by the lamp will be greater than the cost of the lamp itself. Therefore, the optimal voltage was chosen, which is greater than the nominal voltage and minimizes the cost of lighting.

Life time

The life of an incandescent lamp may be limited by the evaporation of the filament material during operation or by inhomogeneities arising in the filament. Since the filament material does not always evaporate evenly, thin areas appear where the electrical resistance becomes greater, and this leads to greater heating and the material begins to evaporate more intensively in such places, since the power in a series electrical circuit is proportional to I r2. Therefore, the lamp burns out when the filament is exhausted so much that the material melts or completely evaporates.

When the voltage is applied suddenly, the filament wears the most, so various soft starters can be used to increase the lamp life.

Specific resistance of tungsten at room temperature twice that of aluminium. When the lamp is turned on, the current exceeds the rated current by 10 - 15 times, so the bulbs burn out at the moment they are turned on. To protect the network from current surges, some lamps (for example, household ones) have a built-in fuse. It can be seen by carefully examining the lamp. This is a conductor that is thinner than the other, connected to the lamp base. At the moment of switching on, the usual household light bulb 60 W consumes over 700 W, and 100 W over 1 kW. When the filament is heated, the resistance increases and the power drops to the nominal value.

A NTC thermistor can be used for soft start. At the moment of switching on, the resistor is cold and has a high resistance, therefore, only after it warms up, the lamp will receive all the voltage. But smooth inclusion is a separate issue.

| Type | Relative light output % | Light output (Lumen/Watt) |

|---|---|---|

| Incandescent lamp 40 W | 1,9 % | 12,6 |

| Incandescent lamp 60 W | 2,1 % | 14,5 |

| Incandescent lamp 100 W | 2,6 % | 17,5 |

| Halogen lamps | 2,3 % | 16 |

| Halogen lamps (with quartz glass) | 3,5 % | 24 |

| High temperature incandescent lamp | 5,1 % | 35 |

| Black body at 4000 K | 7,0 % | 47,5 |

| Black body at 7000 K | 14 % | 95 |

| Perfect white light source | 35,5 % | 242,5 |

| Source of monochromatic green light with a wavelength of 555 nm | 100 % | 683 |

Thanks to the table below, you can approximately find out the ratio of power and luminous flux for an ordinary bulb "pear" (base E27, 220 V).

| Power, W) | Luminous flux (lm) | Luminous efficacy (lm/W) |

|---|---|---|

| 200 | 3100 | 15,5 |

| 150 | 2200 | 14,6 |

| 100 | 1200 | 13,6 |

| 75 | 940 | 12,5 |

| 60 | 720 | 12 |

| 40 | 420 | 10,5 |

| 25 | 230 | 9,2 |

| 15 | 90 | 6 |

Varieties of incandescent lamps

vacuum(the simplest type of light bulb);

Argon(nitrogen-argon);

Krypton(10% brighter than argon);

Xenon(brighter than argon two times);

Halogen(I or Br is used as a filler, such bulbs are 2.5 times brighter than argon bulbs, have a longer service life and do not like undercooking, since the halogen cycle stops working);

Halogen with two flasks(better heating of the inner flask increases the efficiency of the halogen cycle);

xenon halogen(Xe + I or Br is used as a filler, the most effective filler, the brightness is 3 times better than that of argon ones);

Xenon-halogen with IR reflector(since the main part of the radiation is in the IR range, the reflection of IR radiation inwards allows you to significantly increase the efficiency, such lamps can be found in hunting lamps);

Incandescent with a coating that converts infrared radiation to the visible range. At the moment, a lamp is being developed with a high-temperature phosphor, which, when heated, emits the visible spectrum;

Advantages and disadvantages of incandescent lamps

Advantages:

- high color rendering index, Ra 100;

- stable mass production;

- low cost;

- compact dimensions;

- there is no ballast;

- not afraid of ionizing radiation;

- purely active electrical resistance (unit power factor);

- ignition and re-ignition occurs instantly;

- resistant to power failures and power surges;

- does not contain toxic elements, so there is no need for collection and disposal points;

- can work on any kind of current;

- insensitivity to voltage polarity;

- you can make a lamp for any voltage (from fractions of a volt to hundreds of volts);

- when working on alternating current, there is no flicker (important in enterprises);

- when working on alternating current, there is no buzz;

- continuous emission spectrum;

- familiar and pleasant spectrum in everyday life;

- resistance to electromagnetic impulse;

- can work with brightness controls;

- not afraid of low and high temperatures environment, resistance to condensate;

Flaws:

- low light output;

- short service life;

- fragility, it is desirable to avoid shocks or vibrations;

- very large current surge when turned on (about ten times);

- in case of thermal shock or rupture of the thread under tension, the cylinder may explode;

- dependence of luminous efficiency and service life on voltage;

- may cause a fire. Already after 30 minutes the external surface of the lamp has a high temperature, which depends on the power: 25 W - 100 °C, 40 W - 145 °C, 75 W - 250 °C, 100 W - 290 °C, 200 W - 330 °C . If the lamp is placed on a textile material, the bulb will heat up even more. An ordinary 60 W light bulb is capable of igniting straw after 67 minutes of operation;

- since parts of the lamp heat up, heat-resistant fittings of fixtures are required;

- low light efficiency (the ratio of the power of the rays of the visible spectrum to the energy consumed) is about 4%. If you connect an electric lamp through a diode (this is done to extend the life of the lamp on landings or in vestibules), it will only get worse, since the efficiency drops significantly and light flickers appear;

Do you know how incandescent lamps are made? No? Then here is an introductory video from Discovery

And remember, a light bulb stuck in your mouth won't come out, so don't do it. 🙂

Despite the development of energy-saving technology, incandescent lamps still hold leadership in the lighting market.

What does an incandescent lamp look like?

Operating principle

The effect of the lamp is to significantly heat the filament with an electric current. To solid began to glow with red radiation, its temperature must be increased to 570 0 C. It becomes comfortable for the eyes with a 4-5-fold increase in temperature.

Of all metals, tungsten is the most refractory (3400 0 C), therefore, a wire from it is used as a filament. To increase the radiation area, it is rolled into a spiral, which in an incandescent lamp heats up to 2000-2800 0 C. At the same time, the color temperature is 2000-3000K, creating a yellowish spectrum. It is more energy-consuming and dull than daytime, but comfortable for the eyes.

Even in a school textbook, an experiment is given with an increase in the glow of a lamp depending on the strength of the electric current. As it grows, radiation and heat are released.

IN air environment tungsten filament quickly oxidizes and breaks down under high temperature. Previously, a vacuum was created in a glass flask, but now an inert gas is most often used: nitrogen, argon, krypton. At the same time, the strength of the glow increases. In addition, gas pressure prevents the evaporation of tungsten from the glow temperature.

Structure

Despite the apparent ease of manufacture, the lamp consists of 11 elements. At the same time, 7 different metals are used in the design. The most important element is the filament. She may be different types: round, have the form of one or more ribbons. In connection with the variety of elements where light energy is obtained from electrical energy, they are commonly called filaments. The flasks are in most cases round or pear-shaped, but may be of other shapes.

Types of incandescent lamps

The figure below shows the design of the lamp. Inside are electrodes (6), a spiral (2) (tungsten) and hooks (3) (molybdenum). Plinths (9) made of galvanized steel have been made mainly threaded since the days of Edison. Their diameters may vary: E 14, E 27, E 40 - according to the size of the outer diameter. The base is also connected to the cartridge by means of pins or pins. Its type is determined by the marking embossed on the outer surface.

Incandescent lamp device

Options

- electrical;

- technical (intensity and spectral composition of the light flux);

- operational (conditions of use, dimensions, light output, service life).

Power

The main characteristics are applied in the form of markings. These include the power by which the lamp is chosen (60 W - the most in demand). Here the light characteristic is more important. The table shows the characteristics of household lamps, from which it follows that the light energy from one lamp is more intense than from several, with the same total power. It is, however, cheaper.

Lamp characteristics

| Power, W | 5 | 15 | 25 | 40 | 60 | 75 | 100 |

| Light output, Lm/W | 4 | 8 | 8.8 | 10.4 | 11.8 | 12.5 | 13.8 |

Light energy is spent more on lamps of lower power. Therefore, saving electricity in this way will not work.

Specifications

Light energy depends on the power of an incandescent lamp non-linearly. The output of light increases with its increase, and after 75 W it begins to decrease.

The advantage of incandescent lamps is the uniformity of illumination. The intensity of light they have is almost the same in all directions.

Pulsating light has a negative effect on eye fatigue. A pulsation coefficient of no more than 10% is considered normal during small work. For incandescent lamps, it does not exceed 4%, and worst score observed with a 40 watt lamp.

Incandescent lamps heat up the most. In terms of power consumption, it is more of a space heater, rather than a lighting device. Light output is only 5-15%. In order to save energy, the use of incandescent lamps of 100 W or more is prohibited. A 60 W lamp does not heat up very much, and there is enough lighting for one room.

If we evaluate the emission spectrum, then compared to daylight in incandescent lamps, there is not enough blue light and an excess of red. But it is considered acceptable because it is less tiring for the eyes compared to fluorescent lamps.

Operating parameters

For lamps, the conditions where they are used are important. They can be operated in the temperature range from -60 0 С to +50 0 С, humidity not more than 98% at 20 0 С and pressure not less than 0.75∙10 5 Pa. They don't need additional devices with the exception of dimmers, which smoothly regulate the light output. Lamps are cheap and require no skill to replace.

The disadvantages include: the lowest reliability, strong heating and low efficiency.

Types of incandescent lamps

Although energy-saving light sources have best performance, incandescent lamps remain in first place. This is especially true for home use.

General purpose lamps (LON)

LONs are widely used, despite the fact that only 5% of the energy remains for lighting, and the rest is released as heat. LON are intended for household needs, enterprises, administrative buildings and external lights. They are divided into a stable voltage of 220 V and an increased voltage of up to 250 V. The burning time of the lamps is short and is about 1000 hours.

The first letter of the marking indicates the main feature, for example, C - vacuum, B - bispiral, G - monospiral.

- G 235-245-60-P (monospiral, voltage range 235-245 V, power 60 W, for utility rooms);

- B 230-240-60 (vacuum, 230-240 V, 60 W).

Lamps have a lot of power. The upper limit of 100 W does not apply to them. Lamps are used for directional lighting over long distances: for general-purpose searchlights, film projection and lighthouses. Their filament body has a compact arrangement to improve focusing. It is also provided by a special design of the plinths or by the presence of additional lenses.

![]()

What do spotlights look like?

mirror lamps

A special feature is the special design of the flask and the presence of a reflective screen made of aluminum. To give the light softness and reduce the contrast, the light guide area is made matte. The light distribution is concentrated (ZK), medium (ZS) and wide (ZSh). The composition of the glass of some mirror lamps is changed by adding neodymium oxide to it. This makes them brighter and shifts the color temperature towards white light.

What does a mirror lamp look like?

Lamps are used to illuminate stages, showcases, industrial complexes, medical offices and much more.

Halogen lamps

A feature of the lamp is the presence of halogen compounds in the bulb. When interacting with them, the evaporated tungsten molecules are deposited back onto the spiral, which allows you to create an increased temperature of its heating and double the life of the lamps.

Halogen lamp with pin base

When choosing a lamp, you need to know its features, usually indicated on the label, as well as the purpose of use.

How to turn on incandescent lamps

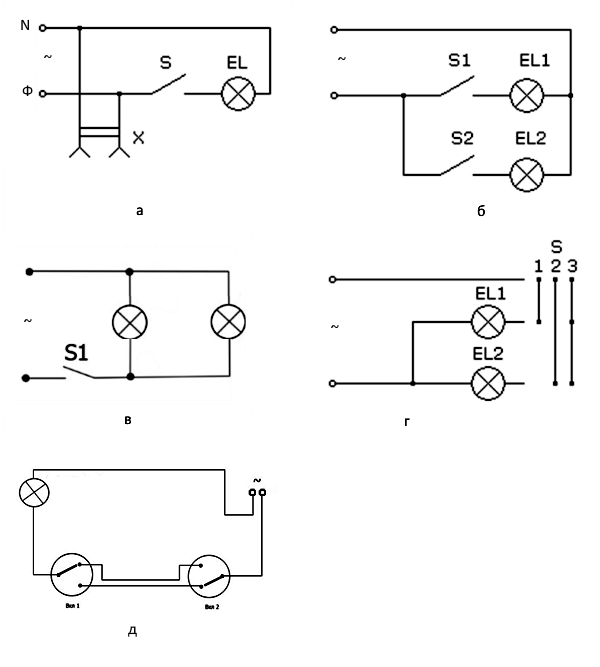

Although incandescent lamps do not require any starting devices, there are rules for connecting them that must be followed. First of all, it connects to the base neutral wire, and phase passes through the switch. When these rules are followed, accidental contact with the base will not cause electric shock.

To supply voltage to all lamps with one switch, they must be connected in parallel.

Lamp connection diagrams

In the circuits, the fixtures are connected in parallel. Usually, a common input is made to the room with sockets, but the switch is connected only to the lamps. Sources can be switched simultaneously (fig. c) or separately (fig. b). In chandeliers, lamps can be combined into groups from one switch. On fig. d shows a diagram of its operation, where 3 switch positions provide all the diagrams of the possible states of two lamps.

For long corridors, 2 pass-through switches are used, through which you can independently work with a lamp made of different places(Fig. e). This is especially convenient for switching outdoor lights from home. When you press one of them, one or more lamps light up or go out. Such a circuit requires more wires.

Ways to improve lamps

Incandescent lamps are developing in the same directions as other light sources: increasing efficiency, reducing energy costs and safe application. For this, a certain gas medium is selected, halogen and quartz-halogen lamps are used, specifications. Many are quite satisfied with the soft and warm light incandescent lamps.

The use of carbon nanotubes as an incandescent body made it possible to increase the light output by a factor of 2 compared to tungsten. Stable lamp parameters are maintained for 3000 hours. The reduced supply voltage makes it safer.

How to increase service life

The reasons for the rapid burnout of the lamps are as follows:

- power supply instability;

- mechanical shock;

- air temperature;

- broken connections in the wiring.

Over time, the filament evaporates, the resistance of the lamp increases, and it burns out. In addition, the resistance of a conventional cold and hot lamp at 60-100 W changes 10 times. The resistance of the cold spiral in a 60 W lamp is 61.5 ohms, and the hot one is 815 ohms. The brighter the light and the more often the inclusion, the more intense the process. In this case, the risk of failure increases towards the end of the service life. In this regard, it is required to select a suitable voltage for normal light output and a sufficient service life.

Ways to ensure the durability of incandescent lamps:

- When buying, choose the appropriate voltage range.

- Carriers are moved in the off state, since the slightest shaking leads to burnout of a working lamp.

- If a light bulb fails quickly in the same socket, it should be repaired or replaced.

- On the landing, a diode is installed in the power circuit or two identical lamps are turned on.

- A soft start device is installed in the break in the power circuit.

Energy saving. Video

You can learn how to save energy in home lighting by watching the video below.

At right choice and how they are used, incandescent lamps can be economical and last a long time. Their low cost, comfortable lighting and ease of use still allow them to take first place among different light sources.

History of occurrence. Device. Choosing a quality lamp

History of lamps. At present, it is difficult to meet a person who would not be familiar with incandescent lamps. Progress in the field of lighting devices has offered alternative light sources - fluorescent and diode lamps, but in some respects they have not yet been able to surpass the ordinary "Ilyich's light bulb".

The history of the incandescent lamp is very complicated and its appearance was preceded by the inventions of many scientists and inventors.

According to the generally accepted version, it began back in 1872, when the Russian scientist A.N. Lodygin guessed to pass an electric current through a carbon rod.

The rod itself was in the airless space of a transparent glass flask. Increasing the current caused more intense light output until the melting point was reached and the lamp went out. So empirically have been established optimal modes work for the first incandescent lamps and a year later - in 1873 in St. Petersburg, several lanterns with such lamps were first tested.

At the same time, in parallel with Lodygin, the American inventor Thomas Edison was engaged in the development of an incandescent lamp. In 1879, he was the first to patent an incandescent lamp with a carbon filament, which subsequently served as the reason that many consider him the real "father of the incandescent lamp."

In fact, as is often the case in the field of technical inventions, the lamp was invented in different countries almost simultaneously, so it is impossible to say with certainty who owns the authorship.

Working on the improvement of a lamp with a carbon filament, Lodygin in 1890 proposed replacing the incandescent filament with a metal one made of refractory metal - tungsten. Unlike other electrically conductive materials, tungsten has a very high melting point, around 3410°C.

At the same time, Edison proposes to use the threaded socket-cartridge system invented by him in the design of lamps. This design has reached our time practically without undergoing any significant changes. The base of incandescent lamps is designated "E-XX", where "E" is the base of Edison (Edison Screw), and "XX" is the outer diameter in mm. In Europe and on the territory of the post-Soviet space, E27 and E14 are widely used.

On the American continent, other base sizes are used to avoid compatibility with European counterparts, since the voltage in the mains is different (120 V. vs. 220 V., respectively). In 1910, the American physicist Langmuir proposed to replace the tungsten filament with one twisted into a thin spiral, which made it possible to reduce the dimensions of the glass bulb, improve the lamp's operating mode and increase light output.

Device. The modern incandescent lamp, despite its apparent simplicity, actually embodies many inventions and discoveries. For the manufacture of incandescent spirals, in addition to expensive tungsten, osmium or their compounds are currently used. The flask ceased to be just a vacuum - very often they began to fill it with an inert gas (argon, krypton, xenon, etc.).

Such a solution made it possible to eliminate the pressure of the atmosphere on the evacuated flask, as well as to increase the total duration of the lamp. The fact is that the electric current passing through the tungsten spiral causes it to heat up and glow. When heated to such high temperatures (up to 2900°C) in an airless flask, tungsten begins to evaporate intensively and settle on the glass. The glass gradually loses its transparency, and the intensity of light output decreases, and the duration of the filament decreases.

We all know how unpleasant it is to look at the bright light of a transparent incandescent lamp, so the industry produces not only transparent flasks, but also matte ones. Due to this, the light turns out to be a little diffused and softer, although it slightly loses in intensity.

We all know how unpleasant it is to look at the bright light of a transparent incandescent lamp, so the industry produces not only transparent flasks, but also matte ones. Due to this, the light turns out to be a little diffused and softer, although it slightly loses in intensity.

Choosing a quality incandescent lamp is not such an easy task as it might seem at first glance. Many people still have light bulbs in their homes that have been in operation for five years or more, and it happens that a recently purchased lamp burns out. The device of an ordinary incandescent lamp is shown in the figure:

where: 1 - glass bulb; 2 - the cavity of the flask filled with an inert gas; 3 - incandescent spiral; 4, 5 - electrodes; 6 - additional spiral supports; 7 - glass leg; 8 - external conductor; 9 - base; 10 - base insulator; 11 - bottom contact of the base.

Choosing an incandescent lamp. When buying a lamp, you should check the glass of the bulb for the presence of foreign inclusions, since only in this case is its sufficient strength ensured. With proper practice, the quality of the glass used can be checked by lightly tapping it with a phalanx of your finger - the sound should be slightly muffled, “strong”. There should be no damage on the metal base - holes or dents.

The presence of a small hole on the base does not mean that the lamp is completely inoperable, but it makes you think about the correctness of the production or transportation processes. The bottom contact of the base can be wide - with a diameter of about 7 mm, or maybe narrow - 5 mm. A wide contact is more preferable, as it provides good contact in the chuck even with a slight displacement of the inner contact plate (tongue).

However, most modern lamps come with narrow bottom contacts, so there may be a situation where there is nothing to choose from. The flask must be securely fixed with the cartridge and not lag behind in the places of gluing. External conductor (8) can be connected to the base or conventional soldering or spot welding.

Soldering should be small and neat, and when welding, hold tight. The glow plug (3) must not sag too much. If this happens, then the lamp has already been used and the spiral has stretched a little. Very important point is an inspection of the quality of the crimping of the spiral at the junctions of the electrodes with it (4, 5).

Insufficient crimping reduces lamp life significantly. For high-quality lamps, the leg (7) does not have holes on the side. The specified operating voltage must be higher than the actual voltage. That is, despite the 220 V standard, it is more profitable to choose lamps with 230-240 V. It should be especially noted that voltage over 240 V drastically reduces the lamp life.

An incandescent lamp uses the effect of heating a conductor (filament) when an electric current flows through it ( thermal effect of current). The temperature of the tungsten filament rises sharply after the current is turned on. The filament emits electromagnetic thermal radiation in accordance with Planck's law. The Planck function has a maximum whose position on the wavelength scale depends on temperature. This maximum shifts with increasing temperature towards shorter wavelengths (Wien's displacement law). To obtain visible radiation, it is necessary that the temperature be on the order of several thousand degrees, ideally 5770 (the temperature of the surface of the Sun). The lower the temperature, the lower the proportion of visible light and the more "red" the radiation appears.

36 W incandescent lamp

Part of consumed electrical energy an incandescent lamp converts into radiation, some goes away as a result of heat conduction and convection processes. Only a small fraction of the radiation lies in the visible light region, the bulk is in the infrared radiation. To increase the efficiency of the lamp and obtain the maximum "white" light, it is necessary to increase the temperature of the filament, which in turn is limited by the properties of the filament material - the melting point. The ideal temperature of 5770 K is unattainable, because at this temperature any known material melts, breaks down and ceases to conduct electricity. Modern incandescent lamps use materials with maximum temperatures melting - tungsten (3410 ° C) and, very rarely, osmium (3045 ° C).

At practically achievable temperatures of 2300-2900 ° C, far from white and not daylight. For this reason, incandescent lamps emit light that appears more "yellow-red" than daylight. To characterize the quality of light, the so-called. Colorful temperature .

In normal air at these temperatures, tungsten would instantly turn into an oxide. For this reason, the tungsten filament is protected by a glass bulb filled with a neutral gas (usually argon). The first lamps were made with evacuated flasks. However, in vacuum high temperatures the tungsten evaporates quickly, making the filament thinner (which causes it to burn out quickly) and darkening the glass bulb as it is deposited on it. Later, the flasks were filled with chemically neutral gases. Vacuum flasks are now used only for lamps low power.

Design

An incandescent lamp consists of a base, contact conductors, a filament, a fuse and a glass bulb filled with a buffer gas and protecting the filament from the environment.

Flask

The glass bulb protects the filament from combustion in the surrounding air. The dimensions of the flask are determined by the rate of deposition of the filament material. Higher wattage lamps require bulbs bigger size so that the deposited filament material is distributed over a large area and does not have a strong effect on transparency.

buffer gas

The flasks of the first lamps were evacuated. Modern lamps are filled with a buffer gas (except for low power lamps, which are still made vacuum). This reduces the rate of evaporation of the filament material. Heat losses arising in this case due to thermal conductivity are reduced by choosing a gas, if possible, with the heaviest molecules. Nitrogen-argon mixtures are an accepted compromise in terms of cost reduction. More expensive lamps contain krypton or xenon (molar masses: nitrogen: 28.0134/mol; argon: 39.948/mol; krypton: 83.798/mol; xenon: 131.293/mol)

Filament

Double helix of an incandescent lamp (Osram 200 W) with contact conductors and filament holders

Since the filament is at room temperature when turned on, its resistance is an order of magnitude less than the operating resistance. Therefore, when turned on, a very large current flows (ten to fourteen times the operating current). As the filament heats up, its resistance increases and the current decreases. Unlike modern lamps, early incandescent lamps with carbon filaments, when turned on, worked on the opposite principle - when heated, their resistance decreased, and the glow slowly increased.

In flashing lamps, a bimetallic switch is built in series with the filament. Due to this, such lamps independently work in a flashing mode.

plinth

In order to open the circuit when an arc ignites and prevent overloading the supply circuit, a fuse is provided in the design of the lamp. It is a piece of thin wire and is located in the base of an incandescent lamp. For household lamps with rated voltage 220 such fuses are usually rated for 7.

efficiency and durability

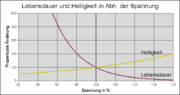

Durability and brightness depending on operating voltage

Almost all of the energy supplied to the lamp is converted into radiation. Losses due to heat conduction and convection are small. For the human eye, however, only a small range of wavelengths of this radiation is available. The main part of the radiation lies in the invisible infrared range and is perceived as heat. The efficiency of incandescent lamps reaches its maximum value of 15% at a temperature of about 3400. At practically achievable temperatures of 2700, the efficiency is 5%.

As the temperature rises, the efficiency of the incandescent lamp increases, but at the same time its durability is significantly reduced. At a filament temperature of 2700, the lamp life is approximately 1000 hours, at 3400 only a few hours. As shown in the figure on the right, when the voltage is increased by 20%, the brightness doubles. At the same time, the lifetime is reduced by 95%.

Reducing the supply voltage, although it lowers the efficiency, but increases the durability. So lowering the voltage by half (for example, when connected in series) greatly reduces the efficiency, but increases the lifetime by almost a thousand times. This effect is often used when it is necessary to provide reliable emergency lighting without special requirements for brightness, for example, in stairwells. Often for this when eating alternating current the lamp is connected in series with the diode, due to which the current flows into the lamp only during half the cycle.

The limited lifetime of an incandescent lamp is due, to a lesser extent, to the evaporation of the filament material during operation, and to a greater extent, inhomogeneities arising in the filament. Uneven evaporation of the filament material leads to the appearance of thinned areas with increased electrical resistance, which in turn leads to even greater heating and evaporation of the material in such places. When one of these constrictions becomes so thin that the filament material at that point melts or completely evaporates, the current is interrupted and the lamp fails.

The predominant part of the wear of the filament occurs when the lamp is suddenly energized, therefore, it is possible to significantly increase its service life using various kinds of soft starters. A tungsten filament has a cold resistivity that is only 2 times higher than that of aluminium. When a lamp burns out, it often happens that the copper wires that connect the base contacts to the spiral holders burn out. So, a conventional 60 W lamp consumes over 700 W at the time of switching on, and a 100-watt lamp consumes more than a kilowatt. As the spiral warms up, its resistance increases, and the power drops to the nominal value.

To smooth out peak power, thermistors with a strongly falling resistance as they warm up, reactive ballast in the form of a capacitance or inductance can be used. The voltage on the lamp increases as the spiral warms up and can be used to shunt the ballast with automatics. Without turning off the ballast, the lamp can lose from 5 to 20% of the power, which can also be beneficial for increasing the resource.

| type | efficiency | Light output( |

|---|